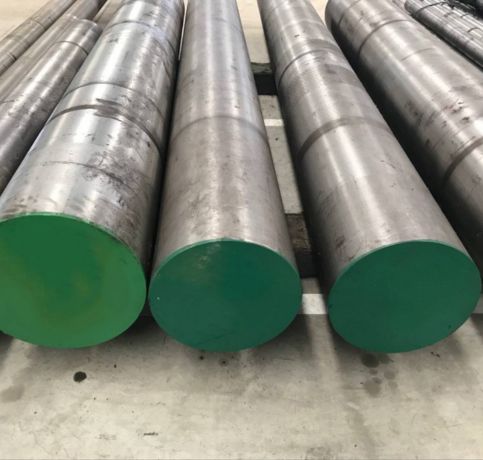

Based in Kolkata, India, Neil Metals is a well-known producer and supplier of high-performance Tool and Die Steel W1 Bars, serving the industrial engineering, die-making, and toolroom industries. Neil Metals provides W1 tool steel bars, which are renowned for their outstanding wear resistance, high hardness, and remarkable machinability, with an emphasis on quality and accuracy. These bars come in a variety of sizes and are made with sophisticated manufacturing processes, making them perfect for cold work applications. Neil Metals provides dependable delivery and consistent product performance for the precision component and toolmaking industries to clients in India and abroad.

Die steel and tools W1 Bars are water-hardening tool steels that can achieve high hardness after quenching because of their high carbon content, which is normally between 0.90 and 1.05%. W1 steel is mostly made of carbon and iron, with trace amounts of silicon and manganese, and has very few alloying elements. W1 steel achieves a hardness of about 60 to 65 HRC after appropriate heat treatment, providing good toughness, wear resistance, and high compressive strength. Its shock resistance and dimensional stability are inferior to those of steels that harden in air or oil, though.

| Element | Content (%) |

|---|---|

| C | 0.70-1.50 |

| Mn | 0.10-0.40 |

| Si | 0.10-0.40 |

| Cr | 0.15 |

| Ni | 0.2 |

| Mo | 0.1 |

| W | 0.15 |

| V | 0.1 |

| Cu | 0.2 |

| P | 0.025 |

| S | 0.025 |

| Properties | Metric | Imperial |

|---|---|---|

| Tensile strength, ultimate | 1680 MPa | 244000 psi |

| Tensile strength, yield | 1500 MPa | 218000 psi |

| Poisson’s ratio (25°C) | 0.27-0.30 | 0.27-0.30 |

| Elongation at break | 3.50% | 3.50% |

| Bulk modulus | 140 GPa | 20300 ksi |

| Shear modulus | 80.0 GPa | 11600 ksi |

| Elastic modulus | 190-210 GPa | 27557-30458 ksi |

| Charpy impact, unnotched | 86.0 J | 63.4 ft-lb |

| Hardness, Brinell (converted from Rockwell C Hardness) | 498 | 498 |

| Hardness, Knoop (converted from Rockwell C Hardness) | 558 | 558 |

| Hardness, Rockwell C | 50.0-51.0 | 50.0-51.0 |

| Hardness, Vickers (converted from Rockwell C Hardness) | 531 | 531 |

| Machinability (based on AISI 1212 steel as 100% machinability) | 40 | 40 |

| Properties | Metric | Imperial |

|---|---|---|

| Density | 7.83 g/cm3 | 0.283 lb/in3 |

| Melting point | 1435°C | 2615°F |

| Properties | Conditions | ||

|---|---|---|---|

| T (ºC) | Treatment | ||

| Thermal expansion | 10.4 x 10-6/ºC | 20-100 | – |

| Thermal conductivity | 48.3 x W/mK | 100 | – |

Tool and Die Steel W1 bars are recyclable, reducing environmental impact. However, their production involves energy-intensive processes. Sustainable practices can enhance their eco-friendliness, such as using recycled materials and cleaner manufacturing methods.

Tool and Die Steel W1 bars are not highly resistant to corrosion, as they are high-carbon steels. They can rust when exposed to moisture, requiring proper maintenance, such as coating or regular oiling, to prevent corrosion.

Tool and Die Steel W1 bars are not ideal for structural applications due to their high carbon content, which makes them brittle and less ductile. They are better suited for tools, dies, and cutting applications where hardness and wear resistance are crucial. For structural applications, steels with better toughness and strength, like carbon or alloy steels, are preferred.

Die steel and tools W1 Bars are frequently utilised in cold work tooling applications where edge retention and high hardness are crucial. Cutting tools, chisels, punches, reamers, drills, hand tools, knives, and razor blades are all made with them. Because of its exceptional machinability and capacity to retain a sharp edge, W1 is also utilised in gauges, template guides, and engraving tools. Because of its water-hardening ability, it can be used in situations where quick cooling is useful. W1 is still an affordable option for precision tools used in metal stamping, woodworking, and general toolmaking, even though it is not the best for high-temperature or high-impact settings.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved