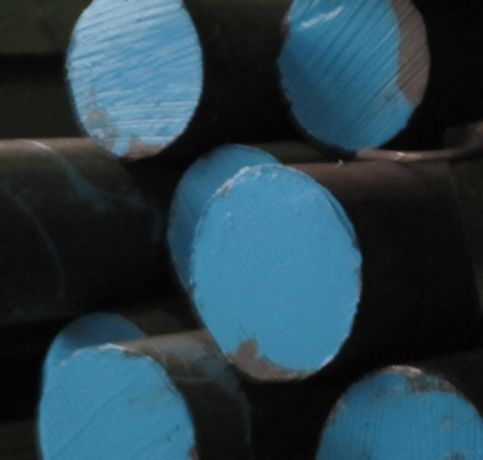

High-performance tool and die steel S7 bars, renowned for their exceptional impact resistance and shock-loading capacity, are the speciality of Neil Metals, a reputable manufacturer and supplier with headquarters in Kolkata, India. Neil Metals supplies S7 tool steel in a range of sizes and specifications to satisfy a variety of industrial needs, serving the automotive, forging, and heavy engineering sectors. The company guarantees consistent product performance and reliability with its cutting-edge infrastructure, strict quality control, and on-time delivery. Neil Metals is dedicated to providing robust, precisely engineered S7 bars that are appropriate for demanding applications that call for strength and toughness under harsh operating conditions.

Die steel and tools The balanced composition of S7 Bars, which are air-hardening tool steels, includes 0.45–0.55% carbon, 3.0–3.5% chromium, 2.0–3.0% nickel, and trace amounts of molybdenum and vanadium. S7 steel, which can be hardened to 55–59 HRC, provides a great mix of toughness, hardness, and shock resistance. It has a high resistance to softening at high temperatures, good machinability, and little distortion during heat treatment. It is perfect for tools that are subjected to high levels of impact and mechanical stress because of these features.

| ASTM A681-2008 | C | Si | Mn | P | S | Cr | V | Mo | ||||||

| S7/T41907 | 0.45 | 0.55 | 0.20 | 1.00 | 0.20 | 0.90 | 0.03 | 0.03 | 3.00 | 3.50 | – | 0.35 | 1.30 | 1.80 |

| DIN ISO 4957 | C | Si | Mn | P | S | Cr | V | Mo | ||||||

| 1.2355/50CrMoV13-15 | 0.45 | 0.55 | 0.20 | 0.80 | 0.50 | 0.90 | 0.03 | 0.02 | 3.00 | 3.50 | 0.15 | 0.35 | 1.30 | 1.70 |

| Properties | Metric |

| Hardness, Rockwell C (air cooled from 941°C, 649°C temper temperature) | 41 |

| Hardness, Rockwell C (air cooled from 941°C, 449°C temper temperature) | 53 |

| Hardness, Rockwell C (air cooled from 941°C, 149°C temper temperature) | 57 |

| Modulus of elasticity | 207 GPa |

| Charpy impact (V-notch; air cooled from 941°C; 425°C temper temperature) | 13.6 J |

| Charpy impact (V-notch; air cooled from 941°C; 649°C temper temperature) | 16.3 J |

| Charpy impact (V-notch; air cooled from 941°C; 200°C temper temperature) | 16.9 J |

| Machinability (1% carbon steel) | 70.0 – 75.0% |

| Poisson’s ratio | 0.27-0.30 |

| Country | USA | German |

| Standard | ASTM A681 | DIN EN ISO 4957 |

| Grades | S7/T41907 | 1.2355/50CrMoV13-15 |

| Properties | Conditions | ||

|---|---|---|---|

| T (°C) | Treatment | ||

| Thermal expansion | 12.6 x 10-6/ºC | 20-200 | – |

The standard annealing temperature for Tool and Die Steel S7 bars is typically around 1,600°F to 1,650°F (871°C to 899°C), followed by slow cooling to relieve internal stresses.

Yes, Tool and Die Steel S7 bars are available in custom lengths and shapes, often tailored to specific customer requirements, ensuring versatility for various tooling and die applications.

Tool and Die Steel S7 bars should be stored in a dry, clean environment, ideally on elevated racks to prevent rust or contamination. They should be kept away from moisture and corrosive substances.

Die and Use a Tool Applications like chisels, shear blades, riveting tools, and pneumatic hammers that demand remarkable shock resistance and toughness frequently use steel S7 bars. S7 is a popular option for cold-work dies, punches, and forming tools in the forging and stamping industries because of its ability to withstand impact without breaking. Additionally, it is used in precision dies and plastic moulds where wear resistance and dimensional stability are crucial. The steel is perfect for high-load and repetitive shock applications because of its adaptability, which enables it to function dependably in both hot and cold working conditions.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved