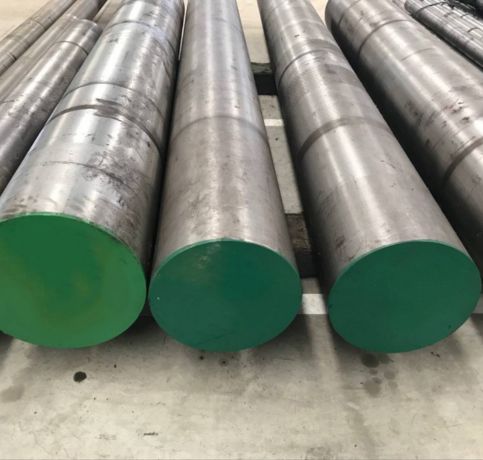

Based in Kolkata, India, Neil Metals is a reputable producer and supplier of high-performance Tool and Die Steel O1 Bars that meet the exacting requirements of the die and toolmaking industries. O1 tool steel bars from Neil Metals are well-known for offering premium materials with precise specifications and outstanding finish, making them perfect for cold work applications. These oil-hardening bars provide a dependable blend of toughness, hardness, and dimensional stability. Neil Metals provides premium O1 steel bars at affordable prices to a range of industries, including general engineering, automotive, and aerospace, with a dedication to on-time delivery and quality control.

Die steel and tools Approximately 0.90 to 1.00% carbon, 0.50% manganese, 0.60% chromium, and trace amounts of vanadium and tungsten are present in O1 Bars, which are oil-hardening cold work steels. Excellent wear resistance and edge retention are provided by this composition. After heat treatment, O1 steel typically has a hardness of 57–62 HRC, good toughness, and little distortion when quenched. In addition to its dependable machinability when annealed, it possesses a tensile strength of 900–1100 MPa. These bars are particularly well-suited for uses that call for resistance to abrasive wear and a fine cutting edge.

| CHEMICAL PROPERTIES | O1 STEEL (%) |

|---|---|

| Carbon | 0.85-1.00 |

| Manganese | 1.00-1.40 |

| Silicon | 0.50 |

| Chromium | 0.40-0.60 |

| Nickel | 0.30 |

| Tungsten | 0.40-0.60 |

| Vanadium | 0.30 |

| Copper | 0.25 |

| Phosphorus | 0.03 |

| Sulfur | 0.03 |

| MECHANICAL PROPERTIES | O1 STEEL (Imperial) |

|---|---|

| Tensile Strength | 245000 psi |

| Yield Strength | 218000 psi |

| Elongation at Break | 0.00% |

| Modulus of Elasticity | 31000 ksi |

| Hardness (Rockwell) | 50 |

| Hardness (Vickers) | 517 |

| Hardness (Knoop) | 513 |

| Country | USA | German | Japan |

| Standard | ASTM A681 | DIN EN ISO 4957 | JIS G4404 |

| Grades | O1 | 1.2510/100MnCrW4 | SKS3 |

| Properties | Conditions | ||

| T (°C) | Treatment | ||

| Thermal expansion | 10.6 x 10-6/ºC | 20-260 | – |

When choosing O1 tool and die steel bars, consider factors like hardness, wear resistance, machinability, heat treatment requirements, intended application (e.g., cutting, stamping), and cost-effectiveness for long-term use.

O1 tool and die steel bars have moderate resistance to corrosion due to their carbon content and alloy composition. However, they are not stainless and can rust without proper maintenance, such as coating or regular oiling.

O1 tool and die steel can be welded, but it's crucial to preheat and control cooling rates to prevent cracking. Post-welding heat treatment is recommended to restore its hardness and properties.

Die steel and tools Cold working tools that need wear resistance and sharp edges frequently use O1 bars. Cutting tools, punches, forming dies, blanking dies, knives, broaches, and gauges are among the frequently used items. O1 steel is appropriate for intricate mould components and precision-ground tools due to its capacity to preserve dimensional stability during hardening. Additionally, it is utilised in woodworking tools, thread rolling dies, and metal stamping tools where edge retention is essential. O1 bars are preferred in processes that require consistent hardening and low distortion because of their oil-hardening properties, which guarantee long-term dependability and performance.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved