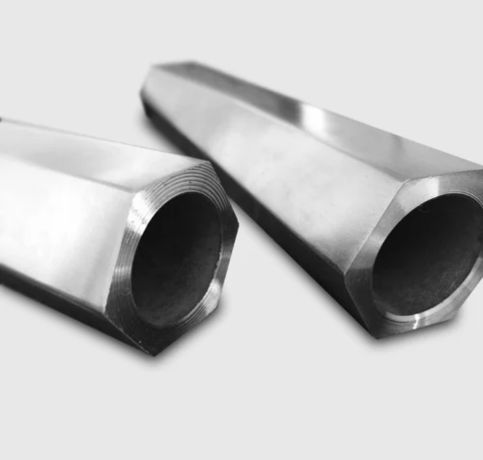

High-quality titanium hollow bars made for demanding industrial and engineering applications are available from Neil Metals, a reputable manufacturer and supplier in Kolkata, India. These hollow bars, which are produced with sophisticated procedures and stringent quality controls, are well-known for their remarkable strength, lightweight design, and superior resistance to corrosion. The aerospace, marine, chemical processing, and medical industries are just a few of the many industries that Neil Metals serves. To satisfy customer demands and international standards, the company offers titanium hollow bars in a range of grades, sizes, and finishes. Neil Metals distinguishes itself as a trustworthy partner for titanium solutions by emphasising accuracy, robustness, and prompt delivery.

Grade 2 (commercially pure titanium) and Grade 5 (Ti-6Al-4V alloy) are the two most common grades of titanium hollow bars. While Grade 5 offers good fatigue strength, heat resistance, and high tensile strength up to 900 MPa, Grade 2 offers exceptional ductility, weldability, and corrosion resistance. Titanium typically makes up 90–99.5% of the composition, with Grade 5 alloying elements like aluminium and vanadium. They are appropriate for structural and precision applications in demanding or weight-sensitive environments due to their low density (4.5 g/cm2), high melting points, and exceptional resistance to oxidising environments.

Hardness, Brinell | 120 | 120 | annealed |

Hardness, Knoop | 132 | 132 | Estimated from Brinell. |

Hardness, Rockwell B | 70 | 70 | annealed |

Hardness, Vickers | 122 | 122 | Estimated from Brinell |

Tensile Strength, Ultimate | 240 MPa | 34800 psi | – |

Tensile Strength, Yield | 170 – 310 MPa | 24700 – 45000 psi | – |

Elongation at Break | 24 % | 24 % | – |

Reduction of Area | 35 % | 35 % | – |

Modulus of Elasticity | 105 GPa | 15200 ksi | In Tension |

Compressive Modulus | 110 GPa | 16000 ksi | – |

Poisson’s Ratio | 0.37 | 0.37 | – |

Charpy Impact | 310 J | 229 ft-lb | V-notch |

Shear Modulus | 45 GPa | 6530 ksi | – |

|

Physical Properties |

Metric |

English |

|

Density |

4.51 g/cc |

0.163 lb/in³ |

|

STANDARD |

WERKSTOFF NR. |

UNS |

|

Titanium |

3.7035 / 3.7165 / 3.7235 |

R50400 / R56400 / R52400 |

Yes, titanium hollow bars are highly recyclable, with the material retaining its strength and properties after recycling. This makes them environmentally friendly and cost-effective for sustainable manufacturing.

Titanium hollow bars offer exceptional strength-to-weight ratio, corrosion resistance, and high-temperature performance, making them ideal for demanding applications. They are also lightweight, durable, and provide excellent machinability.

Yes, we provide bars and rods in standard and customized dimensions and polishes to meet your specific project requirements. For more details mail us on sales@neilmetals.co.in

In aerospace engineering, titanium hollow bars are widely used to create strong, lightweight parts like structural supports and hydraulic tubes. They are perfect for offshore structures, piping systems, and propeller shafts in the marine industry because of their resistance to seawater corrosion. They are utilised in reactors and condensers in chemical processing facilities where aggressive fluid corrosion is an issue. They are appropriate for orthopaedic implants and surgical instruments in the medical field due to their biocompatibility. They are also utilised in the energy, automotive, and defence sectors, where a blend of durability, strength, and resistance to corrosion is essential.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved