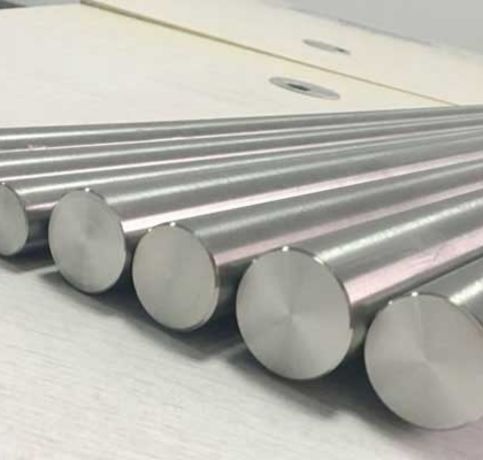

Premium-grade tantalum R05240 bars and rods made to satisfy demanding industrial requirements are available from Neil Metals, a reputable manufacturer and supplier with headquarters in Kolkata, India. These bars are perfect for use in highly corrosive and high-temperature applications because of their remarkable resistance to corrosion, particularly in acidic environments. Tantalum R05240 is available from Neil Metals in a range of sizes and tolerances, guaranteeing that it will work with a variety of specifications. Neil Metals has emerged as a leading supplier of tantalum materials for industries including chemical processing, electronics, and defence both domestically and internationally by placing a high value on product quality, accurate machining, and dependable service.

High-purity, unalloyed tantalum (≥99.95% Ta) with exceptional chemical inertness is known as tantalum R05240. It has a density of 16.65 g/cm³ and a high melting point of about 3017°C. Depending on the processing method, the typical tensile strength is between 200 and 400 MPa, the yield strength is approximately 150 MPa, and the elongation is between 20 and 30 percent. Even at cryogenic temperatures, this grade provides exceptional ductility and formability. It is appropriate for demanding service conditions in chemical and electronic environments due to its exceptional resistance to corrosion from strong acids such as sulphuric, hydrochloric, and nitric acids.

| Specification | ASTM B365, ASME SB365 |

| Tantalum Bar Form | Tantalum Round, Hex, Flat, Half Round, Oval, Rectangular in Black & Bright Finish |

| Tantalum Round Bar Diameter | 0.125″ (3.18mm)~2.5″ (63.5mm) |

| Length | 2-12m |

| Purity | ≥99.95% or 99.99% |

| Tantalum Round Bar Length | 1-12m, Random, Fix & Cut Length or as per clients’ requirement |

| Tantalum | C | O | N | H | Nb | Fe | Ti | W | Mo | Si | Ni | Ta |

| R05240 | 0.010 | 0.020 | 0.010 | 0.0015 | 35.0 – 42.0 | 0.010 | 0.010 | 0.050 | 0.020 | 0.005 | 0.010 | Remainder |

| Grade | Tensile strength δbpsi (MPa), ≥ | Yield strength δ0.2, psi (MPa),≥ | Elongation in 1″/2″ gage length, %, ≥ |

|---|---|---|---|

| R05240 | 40000 (276) | 28000 (193) | 20 |

| 3/16” (4.76mm) | 25mm | 2.1/2” (63.5mm) |

| ¼” (6.35mm) | 1” (25.4mm) | 2.3/4” (69.85mm) |

| 5/16” (7.94mm) | 1.1/8” (28.58mm) | 3” (76.2mm) |

| 3/8” (9.53mm) | 30mm | 3.1/4” (82.55mm) |

| 10mm | 1.1/4” (31.75mm) | 3.1/2” (88.9mm) |

| 12mm | 1.3/8” (34.93mm) | 4” (101.6mm) |

| ½” (12.7mm) | 1.1/2” (38.1mm) | 4.1/2” (114.3mm) |

| 15mm | 40mm | 5” (127mm) |

| 5/8” (15.88mm) | 1.3/4” (44.45mm) | 5.1/2” (139.7mm) |

| ¾” (19.05mm) | 2” (50.8mm) | 6” (152.4mm) |

| 20mm | 2.1/8” (53.98mm) | 7” (177.8mm) |

| 7/8” (22.23mm) | 2.1/4” (57.15mm) | 8” (203.2mm) |

| Size | Kgs / Foot | Kgs / Mtr | Size | Kgs / Foot | Kgs / Mtr | Size | Kgs / Foot | Kgs / Mtr |

|---|---|---|---|---|---|---|---|---|

| 3mm | 0.017 | 0.055 | 20mm | 0.753 | 2.470 | 3″ | 10.900 | 35.762 |

| 1/8″ | 0.019 | 0.062 | 22mm | 0.908 | 2.979 | 3-1/4″ | 12.800 | 41.996 |

| 5/32″ | 0.029 | 0.095 | 7/8″ | 0.926 | 3.038 | 3-1/2″ | 14.850 | 48.772 |

| 4mm | 0.030 | 0.098 | 24mm | 1.080 | 3.543 | 3-3/4″ | 17.001 | 55.780 |

| 3/16″ | 0.043 | 0.141 | 25mm | 1.180 | 3.871 | 4″ | 19.306 | 63.340 |

| 5mm | 0.047 | 0.154 | 1″ | 1.210 | 3.970 | 4-1/4″ | 21.908 | 72.249 |

| 7/32″ | 0.058 | 0.190 | 26mm | 1.271 | 4.170 | 4-1/2″ | 24.4487 | 80.340 |

| 6mm | 0.068 | 0.223 | 27mm | 1.368 | 4.490 | 4-3/4″ | 27.366 | 90.249 |

| 1/4″ | 0.076 | 0.249 | 1-1/8″ | 1.534 | 5.033 | 5″ | 30.461 | 99.940 |

| 7mm | 0.091 | 0.298 | 30mm | 1.691 | 5.548 | 5-1/2″ | 36.690 | 121.000 |

| 5/16″ | 0.118 | 0.387 | 1-1/4″ | 1.924 | 6.349 | 6″ | 43.860 | 143.900 |

| 8mm | 0.120 | 0.398 | 32mm | 1.894 | 6.314 | 6-1/2″ | 51.093 | 167.630 |

| 9mm | 0.152 | 0.498 | 1-3/8″ | 2.303 | 7.550 | 7″ | 59.432 | 196.000 |

| 3/8″ | 0.170 | 0.557 | 35mm | 2.390 | 7.553 | 7-1/2″ | 68.226 | 225.000 |

| 10mm | 0.189 | 0.620 | 36mm | 2.438 | 7.999 | 8″ | 77.586 | 254.55 |

| 11mm | 0.228 | 0.748 | 38mm | 2.792 | 8.903 | 10″ | 121.048 | 397.140 |

| 7/16″ | 0.232 | 0.761 | 1-1/2″ | 2.715 | 8.951 | |||

| 12mm | 0.271 | 0.889 | 40mm | 3.009 | 9.872 | |||

| 1/2″ | 0.303 | 0.994 | 1-5/8″ | 3.200 | 10.449 | |||

| 13mm | 0.318 | 1.043 | 1-3/4″ | 3.712 | 12.179 | |||

| 14mm | 0.368 | 1.207 | 45mm | 3.807 | 12.555 | |||

| 9/16″ | 0.383 | 1.256 | 1-7/8″ | 4.260 | 13.977 | |||

| 15mm | 0.424 | 1.391 | 48mm | 4.330 | 14.205 | |||

| 5/8″ | 0.473 | 1.551 | 50mm | 4.698 | 15.414 | |||

| 16mm | 0.481 | 1.578 | 2″ | 4.848 | 15.906 | |||

| 17mm | 0.543 | 1.791 | 2-1/8″ | 5.475 | 17.963 | |||

| 11/16″ | 0.573 | 1.880 | 2-1/4″ | 6.135 | 20.128 | |||

| 18mm | 0.610 | 2.001 | 60mm | 6.768 | 22.205 | |||

| 3/4″ | 0.682 | 2.237 | 2-3/8″ | 6.838 | 22.435 | |||

| 2-1/2″ | 7.576 | 24.856 | ||||||

| 2-5/8″ | 8.354 | 27.409 | ||||||

| 2-3/4″ | 9.169 | 30.083 |

Tantalum R05240 bars and rods are highly corrosion-resistant, making them suitable for potable water applications. However, it's essential to confirm material compliance with local regulations for drinking water systems.

Yes, Tantalum R05240 bars are customizable. Manufacturers often offer tailored dimensions, finishes, and specifications to meet unique project requirements across industries, ensuring precision and suitability for specific applications.

Tantalum R05240 bars are highly durable due to their exceptional corrosion resistance, high melting point, and robust mechanical properties, making them ideal for demanding applications in harsh environments.

Because of their resistance to extremely corrosive acids, tantalum R05240 bars and rods are frequently used in the chemical processing industry for equipment like heat exchangers, reactors, and liners. They are employed in the manufacturing of high-performance resistors and capacitors in electronics. Tantalum is used in the aerospace and defence industries for vital parts that are subjected to harsh chemicals and high temperatures. This material is also used in laboratory equipment, medical implants, and semiconductor fabrication. Because it is non-reactive, it can also be used in food-grade and pharmaceutical components, guaranteeing chemical stability and longevity in challenging environments.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved