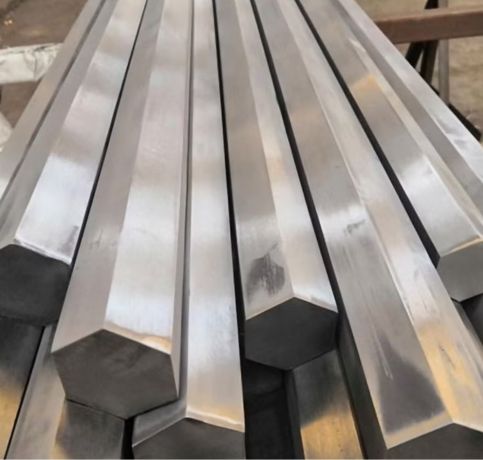

High-performance Super Duplex Steel Hex Bars, designed for use in the most demanding industrial environments, are the speciality of Neil Metals, a reputable manufacturer and supplier with headquarters in Kolkata, India. Our hex bars are perfect for chemical processing, offshore, and marine applications because they combine outstanding mechanical strength with remarkable corrosion resistance. Our Super Duplex hex bars, which are made with sophisticated procedures and stringent quality control, are offered in a range of sizes and specifications and satisfy international standards. Neil Metals is dedicated to providing clients in India and overseas markets with precision, dependability, and timely service while producing high-quality products.

In addition to nitrogen and manganese for strength and corrosion resistance, Super Duplex Steel Hex Bars normally contain 24–26% chromium, 6–8% nickel, and 3–5% molybdenum. This dual-phase alloy has exceptional mechanical strength and toughness because it combines austenitic and ferritic structures. It has a yield strength above 550 MPa and a tensile strength of roughly 750–800 MPa, which is almost twice as high as that of regular stainless steels. Over a broad temperature range, the bars maintain good weldability and impact resistance while demonstrating exceptional resistance to stress corrosion cracking, pitting, and crevice corrosion caused by chloride.

| Standard | : | ASTM / ASME SA 276 / A 479 |

| Grade | : | UNS S 32750, S 32760 , S 32950 |

| Range | : | 10 mm To 100 mm Dia in 100 mm TO 6000 mm Length. |

| Finish | : | Bright Black Polish |

| Form | : | Hexagonal |

| Material | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| Super Duplex Steel | 0.030 max | 1.20 max | 0.80 max | 0.035 max | 0.020 max | 24.00 – 26.00 | 3.00 – 5.00 | 6.00 – 8.00 | 0.24 – 0.32 | 58.095 min |

| Tensile Strength | 90,000 psi |

| Yield Strength | 50,000 psi |

| Elongation In 2” | 20% |

Reduction of Area | 30% |

Brlnell Hardness | 180-220 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.8 g/cm3 | 1350 °C (2460 °F) | Psi – 80000 , MPa – 550 | Psi – 116000 , MPa – 800 | 15 % |

| Size (inch) | sizes in mm | Thickness (in Inches) | Thickness (mm) |

|---|---|---|---|

| 1-3/16 | 30 | 3/16 – 4/5 | 5 to 20 |

| 1 | 25 | 3/16 – 4/5 | 5 to 20 |

| 1-1/4 | 32 | 1/4 – 4/5 | 6 to 20 |

| 1-7/9 | 45 | 3/16 – 1 | 5 to 25 |

| 1-4/7 | 40 | 3/16 – 1 | 5 to 25 |

| 1-3/8 | 35 | 3/16 – 3/16 | 5 to 20 |

| 2 | 50 | 3/16 – 1-1/4 | 5 to 32 |

| 1-6/7 | 47 | 2/3, 1 & 1-1/4 | 17,25 & 32 |

| 2-1/16 | 55 | 3/16 – 1 | 5 to 25 |

| 2-3/8 | 60 | 3/16 – 1-3/8 | 5 to 35 |

| 7/8 | 22 | 2/3 – 5/7 | 17 & 18 |

| 2-1/4 | 57 | 1-1/4 | 32 |

Applications requiring strength, durability, and resistance to corrosion make extensive use of Super Duplex Steel Hex Bars. Because of their resistance to saltwater and chlorides, they are essential parts of desalination systems, offshore platforms, subsea equipment, and marine applications. They are employed in the production of connectors, pumps, heat exchangers, and valves in the petrochemical and chemical industries. They are appropriate for fasteners, shafts, and structural frameworks in mechanical engineering and construction due to their high load-bearing capacity. Power plants, pulp and paper mills, and pollution control systems—where dependability under challenging circumstances is critical—also depend heavily on these hex bars.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved