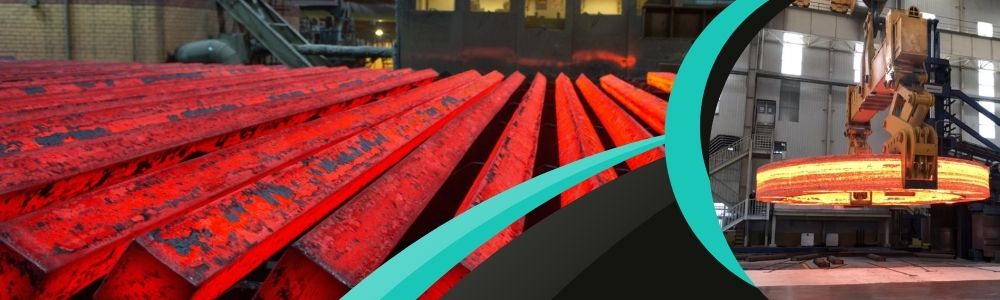

Premium-grade Super Duplex Steel Forgings designed to satisfy the most demanding industrial requirements are available from Neil Metals, a well-known manufacturer and supplier with headquarters in Kolkata, India. Our forgings are well-known for their outstanding resistance to corrosion and superior mechanical strength, making them perfect for harsh environments and high pressure. Super Duplex forgings from Neil Metals, which are made with sophisticated forging methods and stringent quality controls, come in a range of sizes and shapes to accommodate uses in the petrochemical, chemical, offshore, and marine industries. We are known for our accuracy, dependability, and prompt delivery, and we consistently provide excellent service to clients in India and abroad.

Super Duplex Steel forgings contain 50–55% iron, 22–25% chromium, 4–7% nickel, 3–5% molybdenum, 0.1–0.5% nitrogen, and small quantities of copper, manganese, and silicon. The alloy is resistant to corrosion, especially in chloride-rich environments. The material has a tensile strength of 800-1000 MPa and a yield strength of 550-700 MPa. The hardness is between 250 to 350 HV. It also has good ductility and toughness, with elongation usually in the range of 25-40%. The high resistance of the steel to stress corrosion cracking and pitting improves its performance in extreme conditions.

| Standard | ASTM A182, ASME SA182 |

| Specification | DIN, ASTM, BS and all International Standards |

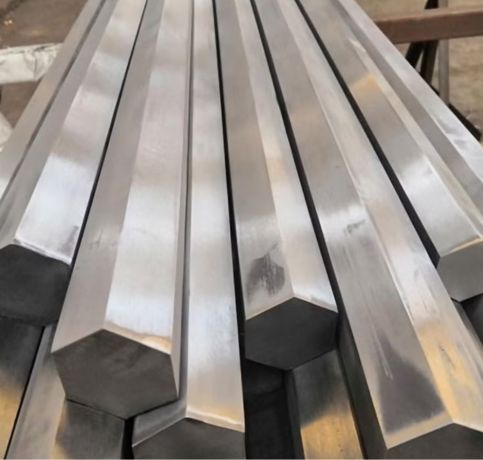

| Flat bar blocks | up to 27″ width and 15,000 lbs. |

| Cylinders and sleeves | up to 50″ maximum O.D. and 65″ maximum length |

| Discs and hubs | up to 50″ diameter and 20,000 lbs. |

| Rolled, hand forged or mandrel forged rings | up to 84″ maximum O.D. and 40″ maximum length |

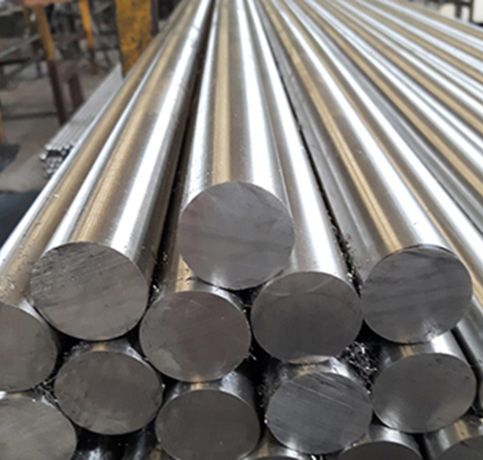

| Rounds, shafts and step shafts | up to 144″ maximum length and 20,000 lbs. |

| Forging Types | Impression Die Forging, Open Die Forging, Seamless Rolled Forging, Hot Forging, Cold Forging, Open die hammer forging, Impression die drop forging, Closed Die Forging, Press Forging, Upset Forging, Compression Forging, Swaging, Rotary Forging, Roll forging. |

Industries that require exceptional corrosion resistance and high mechanical strength frequently use super duplex steel forgings. Their ability to function in chloride-rich environments makes them indispensable in subsea systems, pressure vessels, offshore oil and gas platforms, and marine equipment. They are utilised in the petrochemical and chemical industries for shafts, manifolds, pump parts, valves, and flanges. Lighter and more durable structures are made possible by their strong strength. Additionally, pulp and paper mills, heat exchangers, and desalination plants use super duplex forgings. They are the perfect option for critical infrastructure applications because of their dependability in harsh environments.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved