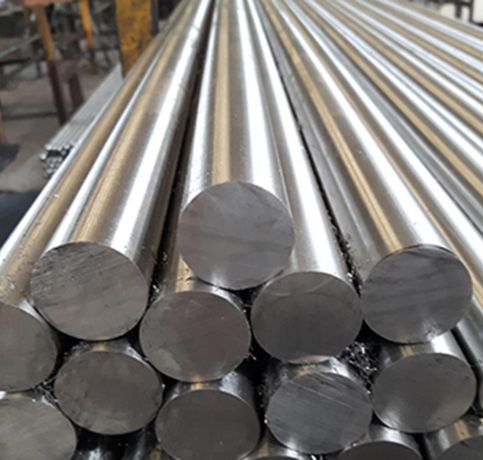

Based in Kolkata, India, Neil Metals is a reputable company in the production and distribution of stainless steel with a focus on providing premium stainless steel hollow bars. Neil Metals is renowned for its accuracy, robustness, and reliable quality. It offers hollow bars that meet a range of industrial needs. Our stainless steel hollow bars are manufactured with cutting-edge techniques and stringent quality checks, providing exceptional strength, resistance to corrosion, and machinability. These products, which are appropriate for both mechanical and structural applications, are supplied with a dedication to prompt service and client satisfaction. Neil Metals proudly serves both domestic and international clients with superior stainless steel solutions.

Depending on the requirements of the application, austenitic grades such as 304, 316, or duplex and super duplex alloys are usually used to make stainless steel hollow bars. They typically contain 8–22% nickel, 16–25% chromium, and trace amounts of silicon, manganese, and molybdenum. These bars have high tensile strength (varying from 485 MPa to 750 MPa depending on the grade), good weldability, and outstanding corrosion resistance. They can be machined into completed parts because they have good elongation, toughness, and pressure resistance. Under chemical and mechanical stress, their smooth structure improves performance.

|

Standard

|

ASTM A511 or equivalent

|

|

Size Range

|

32 x 16 mm – 250 x 200 mm

|

|

Grades

|

316

|

|

Finishes

|

As rolled

|

|

Condition

|

Annealed and pickled

|

|

Processing

|

Bar Cutting

|

|

Outside diameter 1

|

Wall thickness 1

|

Type

|

Specification

|

Quality

|

|---|---|---|---|---|

|

|

11,600

|

Hollow bar

|

EN 10216-5

|

1.4404

|

|

|

20,050

|

Hollow bar

|

EN 10216-5

|

1.4404

|

|

|

9,700

|

Hollow bar

|

EN 10216-5

|

1.4404

|

|

100,000

|

10,000

|

Hollow bar

|

EN 10294-1

|

E470

|

|

100,000

|

10,000

|

Hollow bar

|

EN 10294-1

|

E470

|

|

100,000

|

10,000

|

Hollow bar

|

EN 10216-5

|

1.4306

|

|

100,000

|

10,000

|

Hollow bar

|

EN 10216-5

|

1.4404

|

|

100,000

|

10,000

|

Hollow bar

|

EN 10294-1

|

E470

|

|

100,000

|

10,000

|

Hollow bar

|

ISO2938-

|

20MNV6

|

|

100,000

|

10,000

|

Hollow bar

|

EN 10216-5

|

1.4306

|

|

100,000

|

10,000

|

Hollow bar

|

EN 10216-5

|

1.4404

|

|

100,000

|

12,500

|

Hollow bar

|

EN 10294-1

|

E470

|

|

100,000

|

12,500

|

Hollow bar

|

EN 10294-1

|

E470

|

|

100,000

|

12,500

|

Hollow bar

|

ISO2938-

|

20MNV6

|

|

100,000

|

12,500

|

Hollow bar

|

EN 10294-1

|

E470

|

|

100,000

|

12,500

|

Hollow bar

|

EN 10294-1

|

E470

|

|

100,000

|

14,500

|

Hollow bar

|

EN 10216-5

|

1.4404

|

|

100,000

|

14,500

|

Hollow bar

|

EN 10294-1

|

E470

|

|

100,000

|

14,500

|

Hollow bar

|

ISO2938-

|

20MNV6

|

|

100,000

|

14,500

|

Hollow bar

|

EN 10216-5

|

1.4404

|

|

100,000

|

15,000

|

Hollow bar

|

EN 10294-1

|

E470

|

|

100,000

|

15,000

|

Hollow bar

|

EN 10294-1

|

E470

|

|

100,000

|

15,000

|

Hollow bar

|

EN 10294-1

|

E470

|

|

100,000

|

17,500

|

Hollow bar

|

EN 10294-1

|

E470

|

|

100,000

|

17,500

|

Hollow bar

|

EN 10294-1

|

E470

|

|

100,000

|

18,500

|

Hollow bar

|

EN 10294-1

|

E470

|

|

100,000

|

18,500

|

Hollow bar

|

EN 10294-1

|

E470

|

|

100,000

|

18,500

|

Hollow bar

|

ISO2938-

|

20MNV6

|

|

100,000

|

18,500

|

Hollow bar

|

EN 10216-5

|

1.4404

|

|

100,000

|

20,000

|

Hollow bar

|

EN 10294-1

|

E470

|

|

100,000

|

20,000

|

Hollow bar

|

EN 10294-1

|

E470

|

|

100,000

|

20,000

|

Hollow bar

|

EN 10294-1

|

E470

|

|

100,000

|

22,000

|

Hollow bar

|

EN 10216-5

|

1.4404

|

|

100,000

|

22,000

|

Hollow bar

|

EN 10216-5

|

1.4306

|

|

100,000

|

22,000

|

Hollow bar

|

EN 10294-1

|

E470

|

|

100,000

|

22,000

|

Hollow bar

|

ISO2938-

|

20MNV6

|

|

100,000

|

22,000

|

Hollow bar

|

EN 10216-5

|

1.4404

|

|

100,000

|

22,500

|

Hollow bar

|

EN 10294-1

|

E470

|

|

100,000

|

22,500

|

Hollow bar

|

EN 10294-1

|

E470

|

|

100,000

|

22,500

|

Hollow bar

|

EN 10294-1

|

E470

|

|

100,000

|

45,000

|

Hollow bar

|

EN 10294-1

|

E470

|

|

101,000

|

30,000

|

Hollow bar

|

EN 10294-1

|

E470

|

|

101,600 (3 1/3″)

|

12,500

|

Hollow bar

|

ISO2938-

|

20MNV6

|

|

101,600 (3 1/3″)

|

14,900

|

Hollow bar

|

EN 10294-1

|

OVAKO 280

|

|

101,600 (3 1/3″)

|

16,000

|

Hollow bar

|

ISO2938-

|

20MNV6

|

|

101,600 (3 1/3″)

|

28,000

|

Hollow bar

|

ISO2938-

|

20MNV6

|

|

102,000

|

11,000

|

Hollow bar

|

ISO2938-

|

20MNV6

|

|

105,000

|

12,500

|

Hollow bar

|

EN 10294-1

|

E470

|

|

105,000

|

12,500

|

Hollow bar

|

EN 10294-1

|

E470

|

|

105,000

|

12,500

|

Hollow bar

|

EN 10294-1

|

E470

|

Stainless steel hollow bars offer excellent strength, corrosion resistance, and durability, making them ideal for demanding industrial applications. They are lightweight yet strong, resistant to rust, and perform well in harsh environments like chemicals, high temperatures, and marine conditions. Their versatility suits industries like automotive, aerospace, and construction.

Industries such as automotive, aerospace, construction, and oil & gas benefit greatly from stainless steel hollow bars due to their strength, corrosion resistance, and versatility. These bars are ideal for structural components, hydraulic systems, shafts, and piping, providing reliability in demanding environments like high pressure, extreme temperatures, and exposure to chemicals.

Stainless steel hollow bars are manufactured through processes like extrusion, piercing, or rotary piercing, followed by elongation to form hollow tubes. These bars undergo heat treatment for strength and durability, followed by machining to achieve precise dimensions. The process ensures high-quality, corrosion-resistant, and versatile hollow bars for industrial applications.

Applications needing strength, resistance to corrosion, and effective material use frequently use stainless steel hollow bars. They are perfect for producing precisely machined parts like hollow spindles, pump shafts, valve bodies, and hydraulic cylinders. Hollow bars, which are frequently used in the food and beverage, chemical processing, oil and gas, marine, and power generation industries, help cut down on material waste and machining time. They are appropriate for high-stress mechanical assemblies and pressure vessels due to their superior internal surface finish and dimensional accuracy. Hollow bars made of stainless steel are also utilised in pipelines, instrumentation parts, and architectural structures.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved