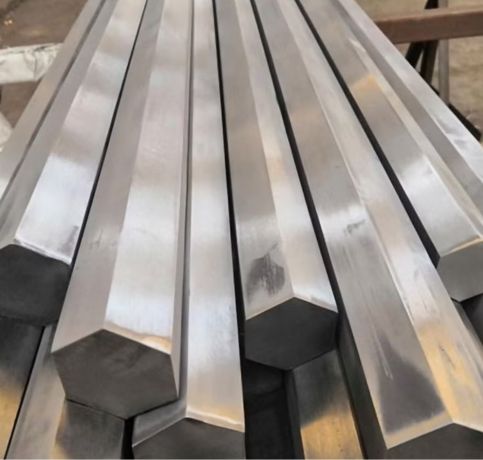

Based in Kolkata, India, Neil Metals is a reputable producer and supplier of premium stainless steel hexagon bars for a variety of engineering and industrial uses. To ensure dimensional accuracy, strength, and resistance to corrosion, our hex bars are meticulously crafted using premium stainless steel and cutting-edge processing technology. Our stainless steel hex bars, which come in a variety of grades and sizes, are perfect for structural and machining applications. Neil Metals is a reputable supplier of long-lasting and high-performing stainless steel products in India and abroad, thanks to its strong dedication to quality, prompt delivery, and customer satisfaction.

304, 316, 410, and 446 grades of stainless steel, which contain 16–25% chromium, 8–22% nickel, and trace elements like silicon, manganese, and molybdenum, are frequently used to make stainless steel hex bars. These bars have good ductility, high tensile strength (from 485 MPa to over 750 MPa), and outstanding corrosion resistance. They may also offer enhanced hardness, magnetic qualities, or heat resistance, depending on the grade. They provide mechanical stability and dependable performance in demanding industrial environments, and their hexagonal shape increases torque strength and makes them appropriate for machining operations.

| Name | Stainless Steel Hexagonal Bars |

| Stainless Steel Hex Bar Standard | EN, AISI, DIN, ASTM, SUS |

| Grades | 304L, 201, 202, 301, 304LN, 309S, 17L, 347, 347H, 316N, 316LN, 304, 316, 316L, 317,3 304N 310S, 316Ti, |

| Stainless Steel Hex Bar Size (Hexagonal bar) | 6 x 6 milimeter to 75 x 75 milimeter |

| Shape | Stainless steel hexagonal bar |

| Price Term | CIF/FOB/CNF or as per need |

| Stainless Steel Hex Bar Length | 5MTR, 4MTR, 6MTR, 3MTR or as per need |

| Application | Architectural Applications, Kitchen Equipment , Sanitary Wares, Furniture, Precision Engineering |

| Stainless Steel Hex Bar Certificate | NDT Test Reports, NABL Approved Lab Test Reports, IGC Practice E Test Reports, Mill TC EN 10204 3.1, |

| Grade | Si | C | Mn | Cr | Ni | N | S | P |

| SS 304 | 0.75 max | 0.03 max | 2 max | 18 – 20 | 8 – 12 | 0.10 Max | 0.030 max | 0.045 max |

| SS 304L | 0.75 max | 0.03 max | 2 max | 18 – 20 | 8 – 12 | 0.10 Max | 0.030 max | 0.045 max |

| SS 316 | 0.75 max | 0.08 max | 2 max | 15 – 18 | 10 – 14 | 0.1 Max | 0.030 max | 0.045 max |

| SS 316L | 0.75 max | 2.00 max | 18.00 max | 14.00 Max | 0.10 Max | 0.1 Max | 0.030 max | 0.045 max |

| Grade | Tensile Strength | Yield Strength (0.2%Offset) | Elongation | Density | Melting Point |

| SS 304 | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 40% | 8.0 g/cm3 | 1400 °C (2550 °F) |

| SS 304L | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 40% | 8.0 g/cm3 | 1400 °C (2550 °F) |

| SS 316 | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % | 8.0 g/cm3 | 1454 °C (2650 °F) |

| SS 316L | 485 Min | 170 Min. | 40 % | 8.0 g/cm3 | 1400 °C (2550 °F) |

| Length in inch | Size in Inch | Weight (lbs/ft) |

|---|---|---|

| 144 | 1/4 | .180 |

| 3/8 | .415 | |

| 7/16 | .565 | |

| 1/2 | .735 | |

| 9/16 | .930 | |

| 5/8 | 1.15 | |

| 11/16 | 1.390 | |

| 3/4 | 1.655 | |

| 7/8 | 2.255 | |

| 1 | 2.945 | |

| 1-1/16 | 3.31 | |

| 1-1/8 | 3.73 | |

| 1-1/4 | 4.60 | |

| 1-3/8 | 5.58 | |

| 1-1/2 | 6.63 | |

| 1-5/8 | 7.78 | |

| 2 | 11.79 | |

| 4 | 47.160 |

| Sizes in Inch | Stainless Steel Hex Bar Sizes In inch |

| H-1/8 | 1/8 |

| H-1/4 | 1/4 |

| H-5/32 | 5/32 |

| H-3/16 | 3/16 |

| H-7/32 | 7/32 |

| H-5/16 | 5/16 |

| H-3/8 | 3/8 |

| H-7/16 | 7/16 |

| H-7/8 | 7/8 |

| H-1/2 | 1/2 |

| H-9/16 | 9/16 |

| H-5/8 | 5/8 |

| H-11/16 | 11/16 |

| H-3/4 | 3/4 |

| H-1 | 1 |

| H-1-1/8 | 1-1/8 |

| H-1-1/4 | 1-1/4 |

| H-2 | 2 |

| H-1-3/8 | 1-3/8 |

| H-1-1/2 | 1-1/2 |

| H-1-5/8 | 1-5/8 |

| H-1-3/4 | 1-3/4 |

| H-1-7/8 | 1-7/8 |

| H-2-1/4 | 2-1/4 |

| H-2-3/4 | 2-3/4 |

| H-2-1/2 | 2-1/2 |

| H-3 | 3 |

| Section | Size, diameter | Permitted overall variation | ||

| Class A | Class B | Class C | ||

| mm | mm | mm | mm | |

| Round | ≧ 6 <75 | 0.05 | 0.025 | 0.013 |

Because of their strength, resistance to corrosion, and ease of machining, stainless steel hex bars are used extensively in many different industries. These bars are perfect for manufacturing machine parts, nuts, bolts, shafts, valves, and fasteners. They are appropriate for applications requiring better grip and torque gearbox because of their hexagonal shape. For structural integrity and performance in corrosive or high-stress environments, industries like chemical processing, automotive, aerospace, marine, oil & gas, and construction depend on stainless steel hex bars. They are the preferred option for mechanical manufacturing and precision engineering applications due to their durability and adaptability.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved