Based in Kolkata, India, Neil Metals is a well-known producer and supplier of premium 904L stainless steel bars and rods. Our SS 904L bars and rods are designed to satisfy difficult industrial requirements and are renowned for their exceptional corrosion resistance, especially in harsh acid and chloride environments. These bars are perfect for crucial applications in sectors like chemical processing, marine, and pharmaceuticals because they are precisely manufactured and adhere to international standards. Neil Metals provides tailored solutions to domestic and international clients looking for long-lasting, high-performance stainless steel products, with a strong emphasis on quality, prompt delivery, and client satisfaction.

Stainless Steel 904L is an austenitic, low-carbon, high-alloy steel that contains 19–23% chromium, 23–28% nickel, 4–5% molybdenum, and 1-2 percent copper. Particularly in harsh conditions with phosphoric or sulphuric acids, this special composition offers exceptional resistance to pitting, crevice corrosion, and stress corrosion cracking. SS 904L bars and rods have excellent formability, good toughness, and tensile strength ranging from 490 to 710 MPa. The alloy is appropriate for demanding and long-lasting structural applications because it is non-magnetic, stable over a broad temperature range, and maintains its mechanical integrity under corrosive and high pressure conditions.

| Grade | SS 904L – UNS N08904 |

|---|---|

| Specification | ASTM A276 UNS N08904, WS 1.4539, AFNOR Z2CNDU 25-20 |

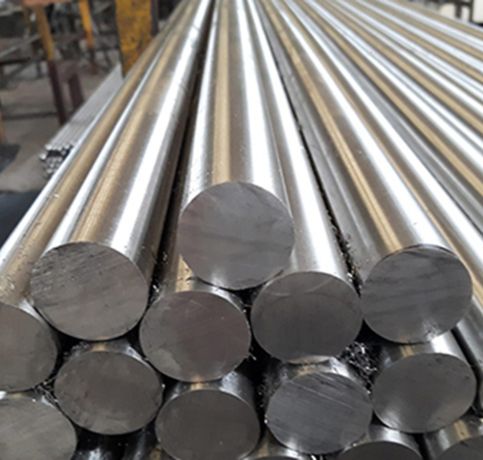

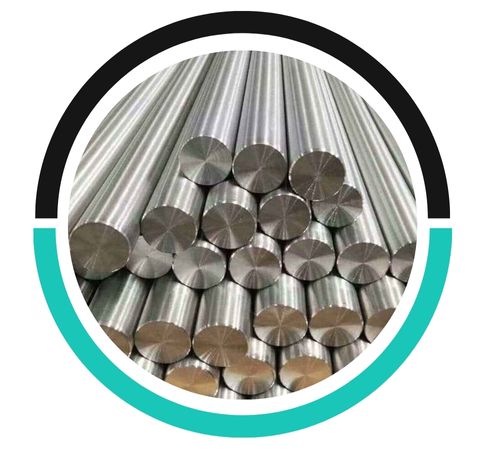

| Round bar size | Diameter: 3-~800mm |

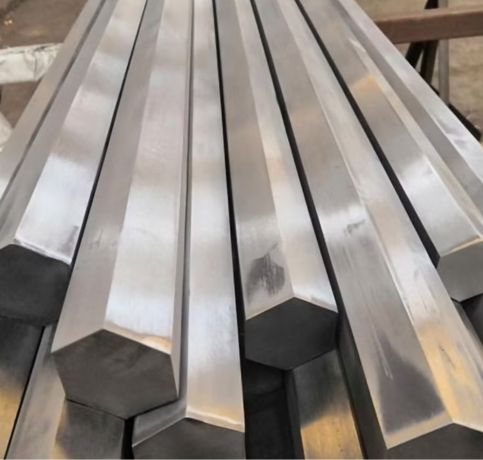

| Hex Bar size | 2-100mm A/F |

| Flat bar size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

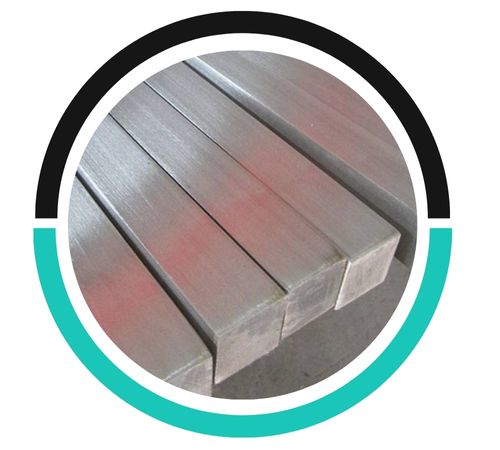

| Square bar size | 4 to 100mm |

| Angle bar size | 3mm*20mm*20mm~12mm*100mm*100mm |

| Section | 3.0 to 12.0mm thickness |

| Channel Bar | 80 x 40mm to 150 x 75mm section; 5.0 to 6.0mm thickness |

| Hollow Bar | 32mm OD x 16mm ID to 250mm OD x 904Lmm ID) |

| Billet Size | 1/2″ to 495mm Diameter |

| Rectangles Size | 33 x 30mm to 295 x 1066mm |

| Round Bar Standard Dimensions | Diameter / Height: |

| Finish | Cold (bright) drawn, centreless ground,smooth turned, peeled, slit rolled edge, hot rolled, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Surface | Bright, Hot Rolled Pickled, Cold Drawn, Sand Blasting Finished, Polished, Hairline |

| Condition | Hardened & tempered, annealed |

| Technique | Stainless Steel 904L Hot Rolled, Cold Drawn, Cold Rolled, Forged Round Bar, Rod |

| Processing | Bar cutting to 650mm |

| Form | Stainless Steel 904L Welding Rod, Round, Rod, T-Bar, Channel Bar, Precision Ground Bar, Flat Bar, Square, Blocks, Round Rod, Rings, Hollow, Triangle, Rectangle, Hex (A/F), Threaded, Half Round Bar, Profiles, Billet, Ingot, I/H Bar, Forging etc. |

| Our stockyad location for fast delivery across India | Coimbatore, Bhubaneswar, Ahmedabad, Bengaluru, Thiruvananthapuram, Agra, Chennai, Noida, Mumbai, Shivamogga, Dhanbad, Hyderabad, Tiruchirappalli, Tirunelveli, Pune, Pimpri-Chinchwad, Navi Mumbai |

| Our Stainless Steel 904L Round bar conforms to NACE MR0175/ISO 15156 | |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Cu |

|---|---|---|---|---|---|---|---|---|---|

| SS 904L | 0.020 max | 2 max | 1 max | 0.040 max | 0.030 max | 19.0-23.0 | 4.0-5.0 max | 23.00 – 28.00 | 1.0-2.0 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 7.95 g/cm3 | 1350 °C (2460 °F) | Psi – 71000 , MPa – 490 | Psi – 32000 , MPa – 220 | 35% |

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | KS | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| SS 904L | 1.4539 | N08904 | SUS 904L | 904S13 | STS 317J5L | Z2 NCDU 25-20 | X1NiCrMoCu25-20-5 |

Industries needing robust resistance to harsh conditions and corrosive chemicals frequently use stainless steel 904L bars and rods. The chemical, petrochemical, and pharmaceutical industries frequently use heat exchangers, chemical storage tanks, gas scrubbers, condenser tubes, and process piping. They are utilised in shipbuilding components, offshore machinery, and seawater handling systems in maritime environments. These bars and rods are also appropriate for equipment used in food handling, pollution control, and pulp and paper processing. They are perfect for high-performance equipment that needs durability, dependability, and little maintenance under demanding service conditions because of their exceptional weldability and formability.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved