Based in Kolkata, India, Neil Metals is a top producer and supplier of high-end stainless steel 440C bars and rods. Neil Metals produces precision-engineered products that satisfy exacting international standards thanks to its state-of-the-art manufacturing facilities and solid foundation in metallurgical expertise. Our 440C bars and rods are renowned for their exceptional hardness, high strength, and resistance to wear. They go through rigorous quality checks to guarantee performance and dependability, making them perfect for high-performance applications. Neil Metals has gained the trust of customers in a variety of industries in India and worldwide thanks to its effective supply chains and customer-focused services.

High-carbon martensitic stainless steel 440C has trace amounts of silicon, manganese, and molybdenum along with roughly 16–18% chromium and 0.95–1.20% carbon. With a tensile strength of up to 760 MPa and outstanding resistance to wear and abrasion, it is well-known for its remarkable hardness and strength following heat treatment. It has a maximum Rockwell hardness of 60 HRC. It works well in mild conditions but is not as resistant to corrosion as austenitic grades. Because of these mechanical characteristics, 440C is appropriate for precision parts that need to be durable and long-lasting.

| Specification | ASTM A479/ SA479 ASTM A276/ ASME SA276 |

|---|---|

| Grade | Stainless Steel 440C (UNS S44004) |

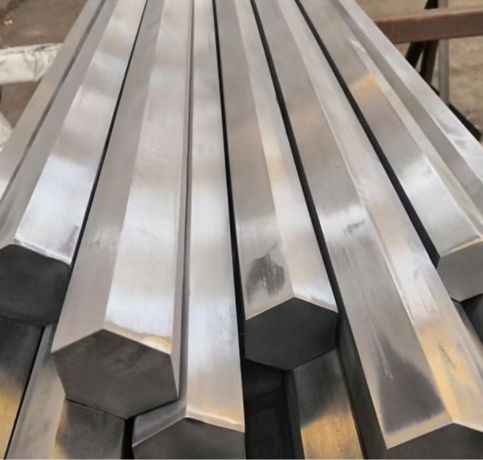

| Hex Bar size | 18 to 57mm (11/16″ – 2-3/4″) |

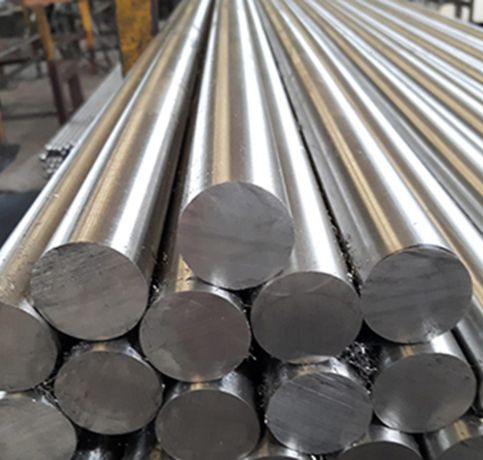

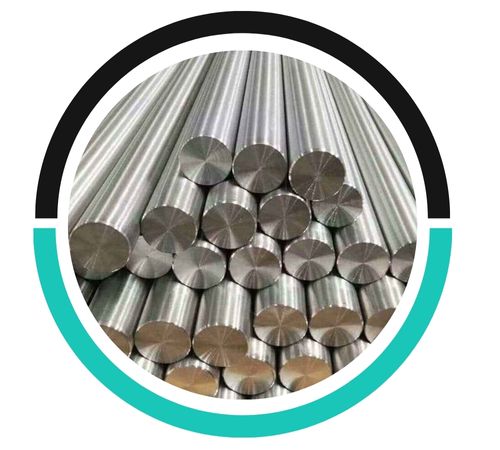

| Round bar size | OD 4mm to 500mm |

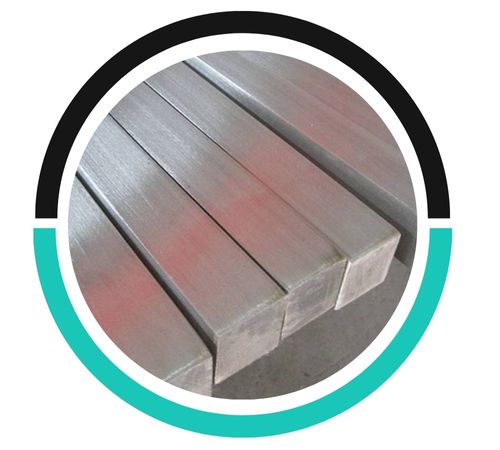

| Square bar size | 18mm to 47mm (11/16″- 1-3/4″) |

| Billet Size | 1/2″- 495mm Dia. |

| Rectangles Size | 33 x 30mm – 295 x 1066mm |

| Bright Bar | OD 4mm to 100mm |

| Tolerance | K12 H12, K10, H9, H11, H8, H13K9, H10, K11, or as per need |

| Flat bar size | 1/2” to 10” in thickness of 2 to 150mm |

| Angle bar size | 3*20*20~12*100*100 |

| Finish | centreless ground, Cold (bright) drawn, hot rolled, peeled, smooth turned, hot rolled annealed, slit rolled edge, Bright, Rough Turned, Grinding, Polish & Black |

| Form | Flat Bar, Hollow, Round, Square, Triangle, Rectangle, Half Round Bar, Rod, T-Bar, Precision Ground Bar, Hex (A/F), Blocks, Channel Bar, Threaded, Round Rod, Billet, Profiles, I/H Bar, Ingot, Rings, Forging etc. |

| Technique | 440C Stainless Steel Hot Rolled, Cold Drawn, Rod, Forged Round Bar, Cold Rolled |

| Condition | annealed, Hardened & tempered |

| Section | 3.0 -12.0 mm thickness, 80 x 40 to 150 x 75mm section |

| Channel Bar | 5.0 – 6.0mm thickness |

| Surface | Bright, Cold Drawn, Hot Rolled Pickled, Sand Blasting Finished, Polished, Hairline |

| Hollow Bar | 32mm OD x 16mm ID – 250mm OD x 200mm ID |

|

SS 440C |

Min |

Max |

|---|---|---|

|

Si |

– |

1.00 |

|

C |

0.95 |

1.20 |

|

Mo |

0.00 |

0.75 |

|

P |

– |

0.04 |

|

Ni |

– |

1.00 |

|

Mn |

– |

1.00 |

|

Cr |

16.00 |

18.00 |

|

S |

0.15 |

0.03 |

|

Element |

SS 440C |

|---|---|

|

Tensile (UTS)N/mm² |

1965 |

|

Temp°C |

20 |

|

Reductionof Area |

10 |

|

Elongation(50.8mm) %) |

2 |

|

0.2% YieldN/mm² |

1896 |

|

HardnessHRc |

57 |

|

STANDARD |

UNS |

WERKSTOFF NR. |

JIS |

|---|---|---|---|

|

SS 440C |

S44004 |

1.4125 |

SUS 440C |

Applications requiring high strength, hardness, and wear resistance frequently use stainless steel 440C bars and rods. Because of its exceptional machinability and toughness, 440C is frequently used in the production of ball bearings, valve components, surgical instruments, and high-performance cutting tools. Additionally, it is utilised in mould production, automotive parts, and aerospace components. It is the material of choice for industrial tools and knife blades because of its hardness and edge retention qualities. 440C provides dependable performance in conditions with moderate corrosion exposure, which makes it perfect for precision mechanical, engineering, and defence applications.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved