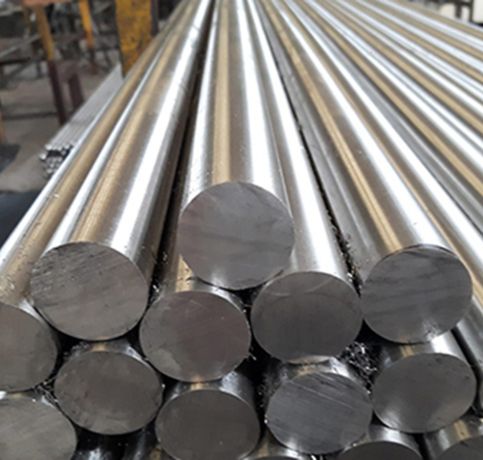

Reputable manufacturer and supplier Neil Metals, with headquarters in Kolkata, India, specialises in providing premium stainless steel 420 round bars for a range of industrial uses. Our SS 420 round bars are famed for their exceptional strength, high hardness, and good resistance to corrosion because they are made with high-quality raw materials and sophisticated manufacturing processes. To satisfy particular client needs, these bars come in a variety of sizes and finishes. Neil Metals has a strong reputation in both domestic and foreign markets thanks to its stringent quality control, prompt delivery, and technical know-how. It serves a wide range of industries, including the tools, machinery, automotive, and medical sectors.

Stainless Steel 420 is a martensitic stainless steel with 0.15–0.40% carbon and 12–14% chromium. Heat treatment can harden it, giving it exceptional wear resistance and tensile strength (up to 700–850 MPa). SS 420 round bars are magnetic in both annealed and hardened states and provide good corrosion resistance in mild environments. They are appropriate for applications needing strength and hardness because they also offer fair ductility and moderate toughness. When exposed to mild acids, steam, and fresh water, the alloy continues to function as intended.

Stainless Steel Round Bar Specification : ASTM A276 / A479, ASME SA276 / A479

Dimension Standard : EN, DIN, JIS, ASTM, BS, ASME, AISI

Size : 14mm-300mm

Thickness : 50 mm to 6000 mm Long

Length : 1 To 6 Meters, Custom Cut Length

Form : Round, Square, Hex(A/F), Rectangle, Billet, Ingot, Forging Etc.

| Grade | C | Mn | Si | P | S | Cr | |

| 420 | min. | – | – | – | – | – | 12.0 |

| max. | 0.15 | 1.0 | 1.00 | 0.04 | 0.03 | 14.0 | |

| Grade | Tensile Strength (ksi) min | Elongation (% in 50mm) min | Yield Strength 0.2% Proof (ksi) min | Hardness |

| 420 | 95,000 | 25 | 50,000 | 175 |

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 420 | 1.4021 | S42000 | SUS 420 J1 | 420S29 | – | – | FeMi35Cr20Cu4Mo2 |

|

Type |

SIZES (mm) |

SIZES (Inches) |

ISO Tolerance |

|---|---|---|---|

|

Cold Drawn and Polish |

3.00 – 75.00 |

1/8″ – 3.00″ |

h8-h9-h10-h11 |

|

Cold Drawn and Ground |

10.00 – 75.00 |

5/6″ – 2.50″ |

h8-h9-h10-h11 |

|

Peeled and Polished |

40.00 – 150.00 |

1.50″ – 6.00″ |

h11, h11-DIN 1013 |

|

Peeled and Ground |

20.00 – 50.00 |

3/4″ – 2.00″ |

h9-h10-h11 |

|

5.0 |

45.0 |

|

6.0 |

50.0 |

|

7.0 |

55.0 |

|

8.0 |

60.0 |

|

9.0 |

65.0 |

|

10.0 |

70.0 |

|

12.0 |

75.0 |

|

16.0 |

80.0 |

|

20.0 |

90.0 |

|

25.0 |

100.0 |

|

30.0 |

130.0 |

|

35.0 |

160.0 |

|

40.0 |

200.0 |

Industries that require high strength, moderate corrosion resistance, and wear resistance frequently use stainless steel 420 round bars. Surgical instruments, cutlery, shear blades, valve parts, shafts, moulds, and fasteners are examples of common applications. They are utilised for gears, bearings, and other precise parts that are subjected to mechanical stress in the engineering and automotive industries. They are perfect for industrial machinery parts and tooling because they can be hardened. Additionally, SS 420 round bars are used in the chemical, oil and gas, and food processing industries where mechanical durability and cleanliness are crucial in mildly corrosive settings.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved