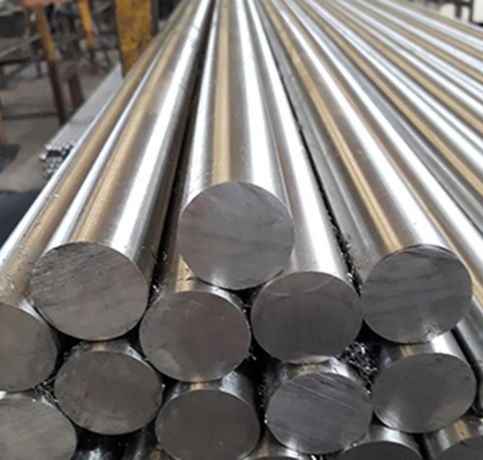

Neil Metals, located in Kolkata, India, has built a solid reputation as a reliable manufacturer and supplier of top-notch Stainless Steel 410 Round Bars and Rods. These products are celebrated for their precision, durability, and impressive wear resistance, all thanks to the use of high-quality raw materials and cutting-edge manufacturing techniques. With a strong focus on quality and customer satisfaction, Neil Metals serves a variety of industries, ensuring their offerings meet both national and international standards. Their SS 410 Round Bars and Rods are particularly valued for their strength, resistance to corrosion, and superb finish, making them perfect for demanding industrial applications.

The composition of Stainless Steel 410 Round Bars and Rods primarily includes chromium (11.5–13.5%), along with trace amounts of carbon, manganese, silicon, phosphorus, sulfur, and iron as the base metal. This martensitic steel grade is known for its excellent hardness and moderate resistance to corrosion. It boasts a tensile strength of about 500–700 MPa and a yield strength of around 275 MPa, along with good toughness and machinability. Plus, the material can be heat-treated to boost its mechanical properties, enhancing wear and impact resistance, which is crucial for high-stress environments.

Stainless Steel Round Bar Specification : ASTM A276 / A479, ASME SA276 / A479

Dimension Standard : EN, DIN, JIS, ASTM, BS, ASME, AISI

Size : 14mm-300mm

Thickness : 50 mm to 6000 mm Long

Length : 1 To 6 Meters, Custom Cut Length

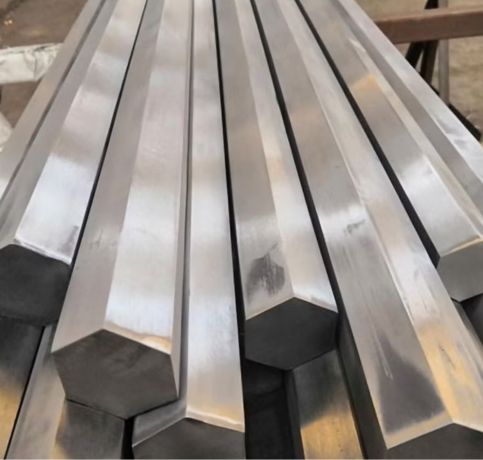

Form : Round, Square, Hex(A/F), Rectangle, Billet, Ingot, Forging Etc.

| Element | S | Cr | Si | C | P | Mn | Ni |

| SS 410 | 0.030 | 11.5-13.5 | 1.00 | 0.15 | 0.040 | 1.00 | 0.75 |

| Elongation | Melting Point | Yield Strength (0.2%Offset) | Density | Tensile Strength |

| – | – | MPa – 275 | – | MPa – 480 |

| STANDARD | UNS | BS | EN | JIS | WERKSTOFF NR. | GOST | AFNOR |

| SS 410 | S41000 | 410S21 | 56A | SUS 410 | 1.4006 | – | – |

Type | SIZES (Inches) | ISO Tolerance | SIZES (mm) |

|---|---|---|---|

Peeled and Polished | 1.50″ to 6.00″ | h11-DIN 1013 | 40.00 to 150.00 |

Cold Drawn and Ground | 5/6″ to 2.50″ | h9-h8-h11-h10 | 10.00 to 75.00 |

Cold Drawn and Polish | 1/8″ to 3.00″ | h9-h8-h11-h10 | 3.00 to 75.00 |

Peeled and Ground | 3/4″ to 2.00″ | h10-h9-h11 | 20.00 to 50.00 |

Cut to size on request (tolerance +2/-0 mm). 410 Stainless Steel Bars Standard lengths of 2000 mm up to 6000 mm.

50.0 | 6.0 |

45.0 | 5.0 |

60.0 | 8.0 |

55.0 | 7.0 |

70.0 | 10.0 |

65.0 | 9.0 |

75.0 | 12.0 |

90.0 | 20.0 |

80.0 | 16.0 |

100.0 | 25.0 |

160.0 | 35.0 |

130.0 | 30.0 |

200.0 | 40.0 |

Cut to size on request (tolerance +2/-0 mm). Standard lengths of 904L Stainless Steel Bars 2000 mm up to 6000 mm available

5.0 | 45.0 |

6.0 | 50.0 |

7.0 | 55.0 |

8.0 | 60.0 |

9.0 | 65.0 |

10.0 | 70.0 |

12.0 | 75.0 |

16.0 | 80.0 |

20.0 | 90.0 |

25.0 | 100.0 |

30.0 | 130.0 |

35.0 | 160.0 |

40.0 | 904L.0 |

Stainless Steel 410 Round Bars/Rod generally does not require additional corrosion protection coatings, as it offers moderate corrosion resistance due to its chromium content. However, in highly corrosive environments, coatings may enhance durability.

When selecting Stainless Steel 410 Round Bars/Rod, consider factors like strength requirements, corrosion resistance, heat treatment needs, and the specific application environment to ensure optimal performance and durability.

Stainless Steel 410 Round Bars/Rod is not ideal for hygienic and sanitary applications due to its moderate corrosion resistance. For such uses, higher grades like 304 or 316 are recommended for better resistance.

Across various industries, Stainless Steel 410 Round Bars and Rods are widely utilized due to their versatility and strength. They are commonly found in the production of fasteners, pump shafts, valves, machine components, and automotive parts. Thanks to their hardness and corrosion resistance, they perform well in environments exposed to mild chemicals, water, and air. These rods and bars also play a vital role in construction, aerospace, and defense sectors, where structural integrity and reliability are paramount. Their adaptability and mechanical performance make them a go-to choice for engineering and industrial applications.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved