Neil Metals stands out as a leading manufacturer and supplier of Stainless Steel 410 Bars and Rods, proudly based in Kolkata, India. They specialize in high-quality, heat-treatable stainless steel products designed for applications that demand strength, hardness, and a bit of corrosion resistance. With a reputation for precision engineering and a commitment to international standards, Neil Metals provides SS 410 bars and rods that are perfect for tough tasks in industries like automotive, engineering, petrochemical, and tooling. Thanks to their state-of-the-art manufacturing facilities and dedication to customer satisfaction, Neil Metals guarantees reliable delivery and consistent quality of Stainless Steel 410 Bars and Rods for both local and global markets.

Stainless Steel 410 Bars and Rods are martensitic stainless steel alloys that contain 11.5–13.5% chromium and up to 0.15% carbon, along with trace amounts of manganese, silicon, and sulfur. This unique blend allows SS 410 to be hardened through heat treatment, achieving a tensile strength of up to 700–900 MPa and a yield strength of around 275 MPa, depending on the temper condition. SS 410 is known for its good wear resistance, moderate corrosion resistance, and excellent machinability, making it a great choice for components that need to be strong and durable in mildly corrosive environments.

| Specification | ASTM A479/ SA479 ASTM A276/ ASME SA276 |

|---|---|

| Grade | Stainless Steel 410 (UNS S41000) |

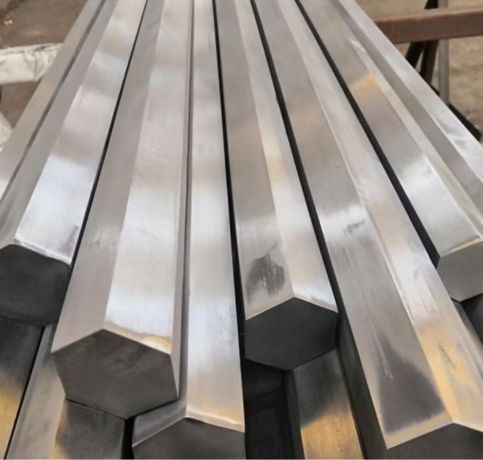

| Hex Bar size | 18 to 57mm (11/16″ – 2-3/4″) |

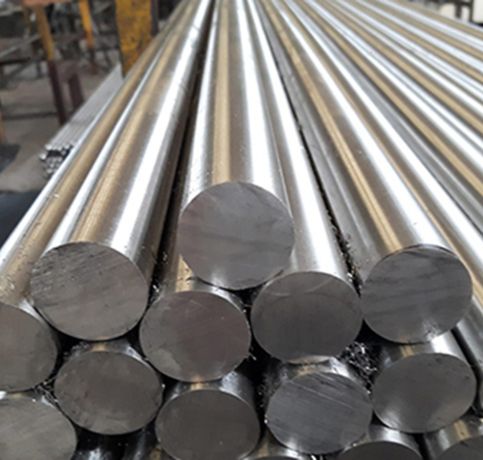

| Round bar size | OD 4mm to 500mm |

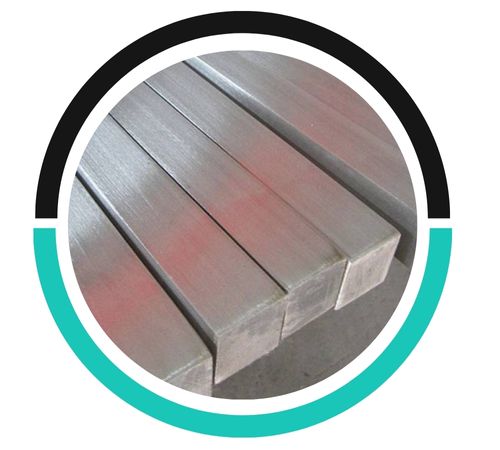

| Square bar size | 18mm to 47mm (11/16″- 1-3/4″) |

| Billet Size | 1/2″- 495mm Dia. |

| Rectangles Size | 33 x 30mm – 295 x 1066mm |

| Bright Bar | OD 4mm to 100mm |

| Tolerance | K12 H12, K10, H9, H11, H8, H13K9, H10, K11, or as per need |

| Flat bar size | 1/2” to 10” in thickness of 2 to 150mm |

| Angle bar size | 3*20*20~12*100*100 |

| Finish | centreless ground, Cold (bright) drawn, hot rolled, peeled, smooth turned, hot rolled annealed, slit rolled edge, Bright, Rough Turned, Grinding, Polish & Black |

| Form | Flat Bar, Hollow, Round, Square, Triangle, Rectangle, Half Round Bar, Rod, T-Bar, Precision Ground Bar, Hex (A/F), Blocks, Channel Bar, Threaded, Round Rod, Billet, Profiles, I/H Bar, Ingot, Rings, Forging etc. |

| Technique | 440C Stainless Steel Hot Rolled, Cold Drawn, Rod, Forged Round Bar, Cold Rolled |

| Condition | annealed, Hardened & tempered |

| Section | 3.0 -12.0 mm thickness, 80 x 40 to 150 x 75mm section |

| Channel Bar | 5.0 – 6.0mm thickness |

| Surface | Bright, Cold Drawn, Hot Rolled Pickled, Sand Blasting Finished, Polished, Hairline |

| Hollow Bar | 32mm OD x 16mm ID – 250mm OD x 200mm ID |

| Element | S | Cr | Si | C | P | Mn | Ni |

| SS 410 | 0.030 | 11.5-13.5 | 1.00 | 0.15 | 0.040 | 1.00 | 0.75 |

| Elongation | Melting Point | Yield Strength (0.2%Offset) | Density | Tensile Strength |

| – | – | MPa – 275 | – | MPa – 480 |

| STANDARD | UNS | BS | EN | JIS | WERKSTOFF NR. | GOST | AFNOR |

| SS 410 | S41000 | 410S21 | 56A | SUS 410 | 1.4006 | – | – |

Stainless Steel 410 Bars and Rods offer excellent wear resistance, good corrosion resistance, and high strength. These properties make them suitable for applications that require strength and durability, such as in the aerospace, automotive, and food processing industries.

These bars and rods are widely used in industries such as petrochemical, chemical processing, power generation, and marine applications. They are also suitable for heat exchangers, boiler parts, furnace components, and high-temperature exhaust systems.

Stainless Steel 410 Bars and Rods are commonly used in the manufacturing of cutlery, surgical instruments, pumps, valves, and shafts, thanks to their combination of strength, corrosion resistance, and machinability. They are also employed in industries like aerospace and automotive.

You’ll find Stainless Steel 410 Bars and Rods in a variety of applications where mechanical strength, hardness, and wear resistance are crucial. Common uses include pump shafts, valves, fasteners, machine parts, kitchen utensils, and components for steam or gas turbines. SS 410 is also popular in the automotive and aerospace sectors for crafting high-strength parts that can handle mechanical stress and friction. Its heat-treatable nature for increased hardness, combined with moderate corrosion resistance, makes it a go-to option for tools, dies, and components that face light chemical exposure and moisture.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved