Neil Metals is a well-respected manufacturer and supplier of Stainless Steel 316L Bars and Rods, located in Kolkata, India. They specialize in providing top-notch stainless steel solutions for critical and high-purity applications. Known for their quality and dependability, Neil Metals offers SS 316L products that adhere to international standards, specifically designed for industries that demand exceptional corrosion resistance and weldability. Their SS 316L bars and rods cater to various sectors, including pharmaceuticals, marine, petrochemical, and food processing. With advanced manufacturing capabilities and a talented workforce, Neil Metals guarantees precise dimensions, a superb surface finish, and timely delivery to both Indian and global markets.

Stainless Steel 316L Bars and Rods are low-carbon variants of SS 316, featuring 16–18% chromium, 10–14% nickel, 2–3% molybdenum, and a maximum carbon content of 0.03%. This lower carbon content improves weldability and reduces the risk of carbide precipitation during welding. SS 316L boasts a tensile strength of about 485 MPa and a yield strength of roughly 170 MPa. It maintains excellent mechanical properties over a wide temperature range and shows outstanding resistance to pitting and crevice corrosion in chloride environments. Its austenitic structure ensures good toughness, even at cryogenic temperatures.

| Specification | ASTM A276/ A479, ASME SA276/SA479 |

|---|---|

| Grade | Stainless Steel 316L (UNS S31603) |

| Flat bar size | 1/2” to 10” in thickness range of 2mm to 150mm |

| Square bar size | 18mm – 47mm (11/16″ to 1-3/4″) |

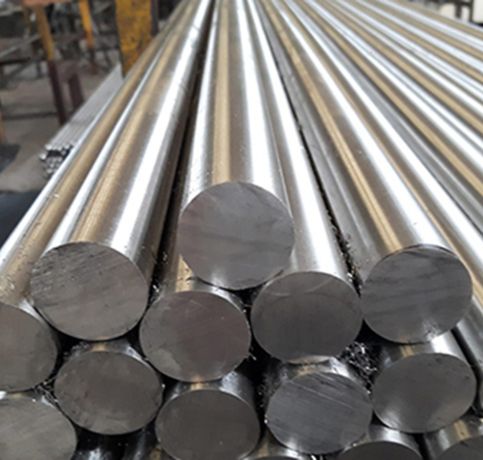

| Round bar size | Outside Diameter in the range of 4mm to 500mm |

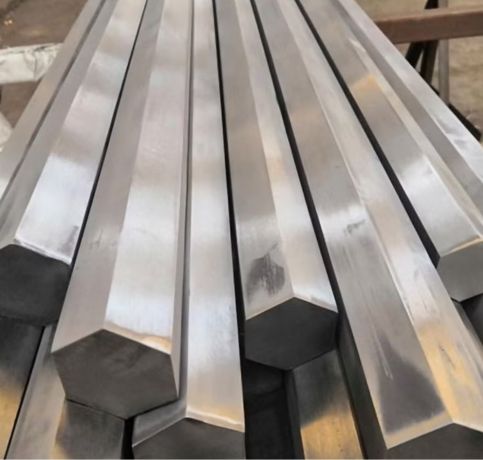

| Hex Bar size | 18mm – 57mm (11/16″ to 2-3/4″) |

| Bright Bar | Outside Diameter in the range of 4mm to 100mm |

| Channel Bar | 80 x 40mm to 150 x 75mm section; 5.0 to 6.0mm thickness |

| Hollow Bar | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| Billet Size | 1/2″ to 495mm Diameter |

| Angle bar size | 3mm*20mm*20mm~12mm*100mm*100mm |

| Rectangular bar Size | 33 x 30mm to 295 x 1066mm |

| Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Surface | Cold Drawn, Bright, Sand Blasting Finished, Hot Rolled Pickled, Hairline, Polished |

| Condition | Hardened & tempered, annealed |

| Technique | 316L Stainless Steel Cold Drawn, Hot Rolled, Forged Round Bar, Rod, Cold Rolled |

| Processing | Bar cutting to 650mm |

| Section | 3.0 to 12.0mm thickness |

| Form | Precision Ground Bar, Flat Bar, Square, Round, Half Round Bar, Rod, Rectangle, Hex (A/F), T-Bar, Channel Bar,Blocks, Round Rod, Threaded, Profiles, Billet, Ingot, I/H Bar, Forging, Rings, Hollow, Triangle etc. |

| Our 316L Stainless Steel Round bar conforms to NACE MR0175/ISO 15156 | |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| SS 316L | 0.3 max | 2 max | 0.75 max | 0.045 max | 0.030 max | 16 – 18 | 2 – 3 | 10 – 14 | 0.10 max |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1454 °C (2650 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 40 % |

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 316L | 1.4404 / 1.4435 | S31603 | SUS 316L | 316S11 / 316S13 | 03Ch17N14M3 / 03Ch17N14M2 | Z3CND17‐11‐02 / Z3CND18‐14‐032 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 |

Stainless Steel 316L contains molybdenum, which enhances resistance to chloride-induced pitting and corrosion, making it highly suitable for marine and coastal applications.

Yes, the low carbon content in 316L minimizes carbide precipitation during welding, ensuring excellent corrosion resistance even in heat-affected zones.

316L bars and rods are widely used in marine, chemical, pharmaceutical, food processing, and medical industries due to their corrosion resistance and durability.

Stainless Steel 316L Bars and Rods are commonly used in industries that require high corrosion resistance and cleanliness. In the pharmaceutical and food processing fields, SS 316L is favored for making equipment, storage vessels, and pipelines due to its low carbon content and non-reactive characteristics. It’s also widely utilized in marine and coastal settings for structural components and fasteners that are exposed to saltwater. Additionally, this alloy finds applications in chemical processing, medical implants, heat exchangers, and architectural projects where welding is necessary and corrosion resistance is crucial. Its excellent formability and non-magnetic properties further enhance its versatility across various industries.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved