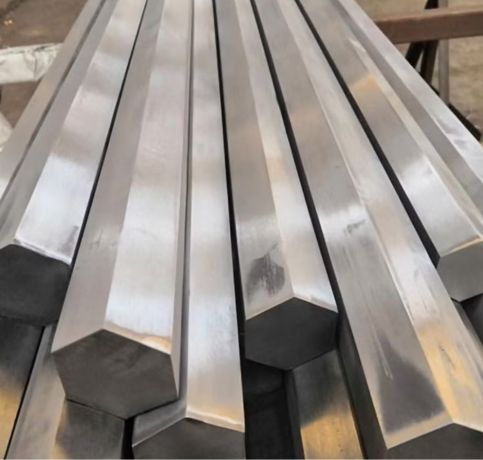

Neil Metals, being a Kolkata-based supplier and manufacturer, specializes in the production of premium **Stainless Steel 253MA Hex Bars and Rods** according to international standards such as UNS S30815 and ASTM A240. Constructed through precision forging and stringent quality-controls, their items provide superior oxidation resistance to 1150 °C and excellent creep strength in austenitic conditions. Used in sectors like power generation, petrochemical, metallurgy, and industrial furnace manufacturers, Neil Metals provides reliable supply, technical assistance, and timely delivery of 253MA bars and rods customized to improve industrial efficiency.

**Stainless Steel 253MA Hex Bars and Rods** have 20–22% chromium, 10–12% nickel, 1.4–2.0% silicon, and 0.14–0.20% nitrogen, trace cerium (0.03–0.08%), and low carbon, manganese, and sulfur content. The lean austenitic alloy features tensile strength between 550–750 MPa, yield strength of 250–350 MPa, elongation of 40–50%, and high impact toughness even at cryogenic temperatures ([metalzenith.com][1]). The alloy exhibits weldability, formability, high-temperature creep, and oxidation resistance, suitable for precision-engineered hex-shaped parts.

Specification : EN, DIN, JIS, ASTM, BS, ASME, AISI

Standard Specification : ASTM A276, A479 / ASME SA276, SA479

Size : 15NB to 150NB IN

Diameter : 3.17mm to 350mm diameter

Length : 100 mm to 3000 mm Long & Above

Tolerance : H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements

Finish : Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish

Form : Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc

Surface : Hot Rolled Pickled or Sand Blasting Finished, Cold Drawn, Bright, Polished, Hairline

Condition : Cold Drawnd Pulished Cold Drawn Centreless Ground & Polished

| Grade | C | Mn | Si | S | N | Cr | Ni |

| 253 MA | 0.05 – 0.1 | 0.8 min | 1.1 – 2.0 | 0.03 min | 0.14 – 0.2 | 20 – 22 | 10 – 12 |

| Element | Density | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 253 MA | 7.8 g/cm3 | Psi – 87,000, MPa – 600 | Psi – 45,000, MPa – 310 | 40 % |

| STANDARD | WERKSTOFF NR. | UNS | EN | SS |

| 253 MA | 1.4835 | S30815 | X9CrNiSiNCe21-11-2 | 2368 |

**Stainless Steel 253MA Hex Bars and Rods** find their application in high-temperature industrial processes. They are employed to make burner nozzles, radiant tubes, and heat exchanger components, kilns, and industrial furnace components, providing superior oxidation resistance in carbon-rich environments. In refinery and petrochemical operations, they are tube hangers, expansion bellows, and mechanical components in furnaces. Their durability up to 1150 °C and machinability render them irreplaceable in power plants, cement kilns, and metallurgical processing machinery where shape accuracy, thermal stability, and durability are of utmost importance.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved