Neil Metals, Kolkata, India, is a reliable producer and supplier of **Stainless Steel 15-5 PH Bars/Rods**, providing premium stainless steel products for critical industrial uses. With a reputation of commitment to precision, reliability, and timely delivery, Neil Metals produces 15-5 PH bars that provide a distinct combination of **high strength, superior corrosion resistance, and good mechanical properties**. These bars are produced with state-of-the-art processes and rigorous quality control procedures, guaranteeing consistency and strength. Aerospace, petrochemical, marine, and power generation industries have come to depend on Neil Metals for reliable stainless steel products designed for demanding performance.

**Stainless Steel 15-5 PH Bars/Rods** are precipitation-hardened martensitic stainless steels with about **15% Chromium**, **4–5% Nickel**, and additions of **Copper (2.5–4%)** and **Niobium/Columbium** for increased strength and toughness. They provide better mechanical properties with a **tensile strength of up to 1310 MPa**, **yield strength of more than 1170 MPa**, and **good impact resistance**. They can be hardened through a simple heat treatment process without scaling or distortion. 15-5 PH also contains good corrosion resistance in most environments, and it’s perfectly suited for corrosive, high-stress, or high-pressure applications.

Dimension : EN, DIN, JIS, ASTM, BS, ASME, AISI

Grade : 15-7MO (UNS No. S15700) Round Bars 1.4532

Finish : Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish

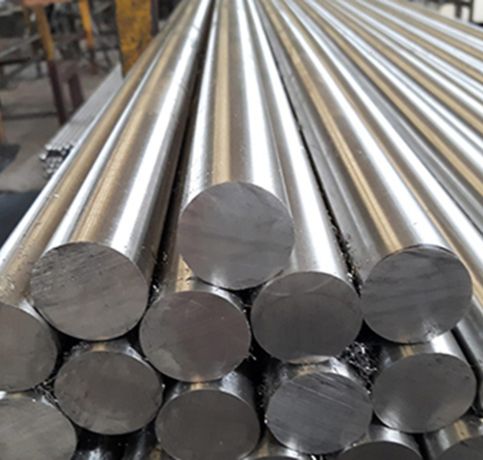

Form : Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc.

Surface : Hot Rolled Pickled or Sand Blasting Finished, Cold Drawn, Bright, Polished, Hairline

Application : Chemical process, Food processing, Petrochemical, Pollution control, Pulp and Paper, Refining

Condition : Cold Drawnd Pulished Cold Drawn Centreless Ground & Polished.

Our 15-7MO Round Bars conforms to NACE MR0175/ISO 15156

| Weight% | C | Mn | Si | P | S | Cr | Ni | Mo | Al |

| 15-7Mo | 0.09 | 1 | 1 | 0.04 | 0.03 | 14-16 | 6.50-7.75 | 2-3 | 0.75-1.5 |

| Material | Condition | Thickness (in) | Tensile Strength (ksi) | Yield Strength (ksi) | Elongation % | Hardness |

| Alloy 15-7 Mo | Solution Treated | <0.005 | 150 (max) | 65 (max) | 25 | 100 HB (max) |

| Alloy 15-7Mo | TH1050 (AMS 5520) | 0.010-0.020 | 190 | 170 | 4 | 40 HRC |

| Alloy 15-7 Mo | TH1050 (AMS 5520) | 0.020-0.1875 | 190 | 170 | 5 | 40 HRC |

| Alloy 15-7 Mo | TH1050 (AMS 5520) | 0.1875-0.500 | 190 | 170 | 6 | 40 HRC |

| Alloy 15-7 Mo | RH950 (AMS 5520) | 0.010-0.020 | 225 | 220 | 3 | 45 HRC |

| Alloy 15-7 Mo | RH950 (AMS 5520) | 0.020-0.1875 | 225 | 220 | 4 | 45 HRC |

| Alloy 15-7 Mo | RH950 (AMS 5520) | 0.1875-0.500 | 225 | 220 | 5 | 45 HRC |

| Alloy 15-7 Mo | Condition C | – | 200 | 175 | 1 | 41 HRC |

| Alloy 15-7 Mo | Condition CH900 | – | 240 | 230 | 1 | 46 HRC |

| STANDARD | WERKSTOFF NR. | UNS |

| SS 15-7MO | 1.4532 | S15700 |

**Stainless Steel 15-5 PH Bars/Rods** find extensive applications in **aerospace parts, shafts, valves, fasteners, marine fittings, petrochemical equipment**, and **nuclear reactor components**. Due to their high strength-to-weight ratio and corrosion and stress cracking resistance, they find applications in **high-pressure uses** like **hydraulic fittings and turbine blades**. These bars are also popular in the **oil & gas**, **chemical processing**, and **defense industries**, where they provide dependable performance under severe operating conditions. The integration of fabrication ease, heat treatability, and structural integrity under load makes 15-5 PH a leading choice for demanding engineering applications.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved