Neil Metals is a reliable maker and supplier of SMO 254 Bars and Rods in Kolkata, India. Being a specialist in high-performance stainless steels, the organization stands out in its ability to supply corrosion-resistant and long-lasting products ideal for rigorous industrial conditions. Guided by quality, accuracy, and innovation, Neil Metals offers SMO 254 Bars and Rods in international standards. Their advanced production units, skilled technical staff, and stringent quality testing guarantee exemplary product performance. Supplying industries such as marine, chemical processing, and power generation, Neil Metals remains a trusted source of premium alloy solutions throughout India and overseas.

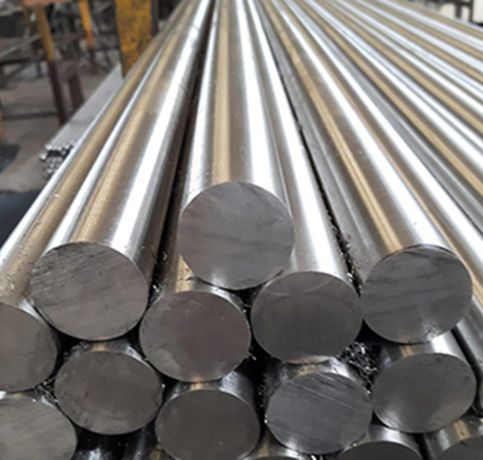

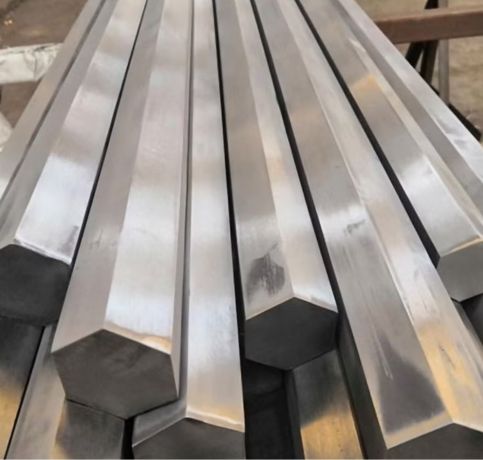

SMO 254 is a high-alloy austenitic stainless steel that has about 20% chromium, 18% nickel, 6% molybdenum, and trace additions of nitrogen and copper. Its exceptional pitting, crevice corrosion, and chloride-induced stress corrosion cracking resistance comes from its distinctive composition. Its mechanical characteristics comprise tensile strength of approximately 650 MPa, yield strength of 300 MPa, and elongation of 35–40%. SMO 254 Bars and Rods are very resistant and have superior weldability and formability. Neil Metals supplies these products in a range of sizes, lengths, and finishes based on specific industry specifications for strength, corrosion resistance, and long service life.

Standards : EN, DIN, JIS, ASTM, BS, ASME, AISI

Size : 1/2″ to 100″

Length : 100 mm to 6000 mm

Specifications : ASTM A276, A279, A479

Form : Round, Square, Hex (A/F), Rectangle, Wire (Coil Form), Wire-mesh, Billet, Ingot, Forging Etc.

Finish : Bright, Polish & Black

| Elements | Carbon | Chromium | Manganese | Molybdenum | Nickel | Nitrogen | Phosphorus | Silicon | Sulphur |

|---|---|---|---|---|---|---|---|---|---|

| SMO 254 UNS S31254 | 0.02 max | 19.5-20.5 | 1.0 max | 6.0-6.5 | 17.5-18.5 | 0.18-0.22 | 0.03 max | 0.8 max | 0.01 max |

| 0.2% Proof Stress (N/mm2 ) [ksi] minimum | 300 [43.5] |

| Tensile Strength (N/mm2) [ksi] minimum | 650 |

| Elongation (%) minimum | 35 |

| Hardness (HBN) | 270 max |

| Reduction of Cross Section Area (%) | 50 |

SMO 254 Bars and Rods are being applied wherever better corrosion resistance is required, particularly in chloride-enriched and acidic conditions. Typical applications include seawater handling systems, desalination plants, heat exchangers, chemical processing equipment, pulp and paper bleaching systems, and offshore oil and gas platforms. As a result of its high strength and resistance to localized corrosion, SMO 254 is best suited for applications in marine components and hydraulic tubing. It also comes into use in flue gas cleaning, food processing, and the pharmaceutical industry where hygiene as well as durability are essential. Its reliability in the long term is a cause for preference in extreme operating conditions.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved