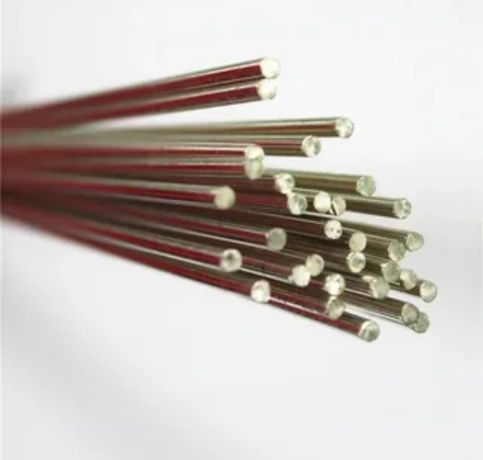

Neil Metals, a well-respected manufacturer and supplier located in Kolkata, India, is known for its top-notch Silver Brazing Rods, which are celebrated for their exceptional bonding strength and durability. With years of experience under their belt and a strong commitment to quality, Neil Metals serves a diverse array of industrial needs, providing products that adhere to both national and international quality standards. Their Silver Brazing Rods are meticulously engineered for seamless joining in various metalworking applications. Industries across the board trust Neil Metals for their timely deliveries, competitive pricing, and steadfast dedication to customer satisfaction.

Typically, Silver Brazing Rods are made up of silver (20–60%), along with copper, zinc, and other trace elements tailored to specific applications. These rods boast impressive mechanical properties, such as high tensile strength, low melting points (around 620–875°C), and remarkable ductility. They create strong, leak-proof joints with excellent corrosion resistance and good electrical conductivity. Designed for optimal capillary action and flow characteristics, these rods excel at joining dissimilar metals while minimizing thermal distortion. Their robust mechanical performance makes them perfect for both light and heavy-duty metal joining tasks.

Silver Grade of Brazing Alloy | Nominal Composition % | Melting Range | International Standards | |||||

Ag | Cu | Zn | Cd | Others | °C | DIN:8513 | AWS:A5.8 | |

| SILVER 67Cd | 67 | 11 | 12 | 10 | – | 635-720 | L-Ag67Cd | – |

| Used for brazing of silver goods made of silver alloys. | ||||||||

| SILVER 50Cd | 50 | 15.5 | 16.5 | 18 | – | 620-640 | L-Ag50Cd | BAg-1a |

| One of the lowest melting point Silver Brazing alloys available. It has excellent flow characteristics. The highest joint strength can be obtained with this alloy. Has better resistance to corrosion in chlorine, sulphur and steam environments. | ||||||||

| SILVER 45Cd | 45 | 15 | 16 | 24 | – | 605-620 | L-Ag45Cd | BAg-1 |

| This has the lowest brazing temperature range of the BAg filler metals. It also flows more freely into narrow clearance capillary joints. Its narrow melting range is suitable for rapid or slow methods of heating. | ||||||||

| SILVER 44Cd | 44 | 27 | 13 | 15 | 1P | 595-660 | – | – |

| Low melting filler metal for brazing electrical contacts and molybdenum or copper-tungsten electrodes. | ||||||||

| SILVER 43Cd | 43 | 16 | 20 | 21 | – | 615-620 | – | – |

| This has the shortest melting range of any silver brazing alloys. This alloy is regarded as the best brazing alloy by manu brazers. It is particularly recommended where a minimum brazing temperature is desirable to preserve the properties of the parent metals. Ideal where joints have a close fitup and will produce neat joints with optimum ductility and strength. | ||||||||

| SILVER 40Cd | 40 | 19 | 21 | 20 | – | 595-630 | L-Ag40Cd | – |

| SILVER 35Cd | 35 | 26 | 21 | 18 | – | 610-700 | L-Ag34Cd | BAg-2 |

| A free flowing general purpose brazing alloy. Its broader melting range is helpful where clearances are wide or are not uniform. Unless heating is rapid, care must be taken that the lower melting constituents do not separate out by liquation. | ||||||||

| SILVER 30Cd | 30 | 28 | 21 | 21 | – | 600-690 | L-Ag30Cd | BAg-2 |

| Similar to Silver 40Cd but more economical. | ||||||||

| SILVER 251Cd | 25 | 30 | 27.5 | 17.5 | – | 605-680 | – | BAg-33 |

| Silver 251, 250 & 20Cd have good fillet forming properties with an ability to bridge wide gaps. Their wide melting range limit their applications. Due to their wide melting range they are somewhat more subject to liquation and may require more care during brazing. Therefore, they are not normally recommended for applications with slow heating rates. | ||||||||

| SILVER 250Cd | 25 | 35 | 26 | 14 | – | 605-745 | – | BAg-27 |

| SILVER 20Cd | 20 | 40 | 25 | 15 | – | 605-765 | L-Ag20Cd | – |

| SILVER 12Cd | 12 | 50 | 31 | 7 | – | 620-825 | L-Ag12Cd | – |

| Economical alloy with wide melting range. Like above, preferred for applications having short heating cycles to avoid liquation. Ideal for bridging wider gaps where work pieces are insensitive to heat. | ||||||||

| SILVER 5Cd | 5 | – | – | 7 | – | 335-392 | – | – |

| Used where alloy having higher melting point and better strength than soft solder is required. | ||||||||

| C | Si | Mn | P | S | Cr |

| 95/1.25 | .40 max. | .37 | .045 max | .045 max. | .35 / .45 |

Silver brazing rods generally do not require corrosion protection coatings for most applications. However, in highly corrosive environments, additional coatings or protective measures may be beneficial to prevent degradation.

Silver brazing rods are not designed for welding, as they are intended for brazing. Attempting to weld them can result in poor joint strength and structural integrity.

When installing silver brazing rods, ensure the joint surfaces are clean and properly prepared for effective bonding. Also, control the heating process to avoid overheating or damaging the material.

Silver Brazing Rods find extensive use in various industries, including HVAC, aerospace, automotive, electrical, and refrigeration, for joining both ferrous and non-ferrous metals. Their low melting point and superb flow characteristics enable precise and clean joints, making them ideal for intricate assemblies. In the electronics field, they are essential for components that require high conductivity. In plumbing and air conditioning systems, they provide reliable, leak-proof seals. Their versatility and reliability also make them suitable for high-stress applications like turbine blades, fuel lines, and structural assemblies, ensuring durability and performance even in demanding conditions.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved