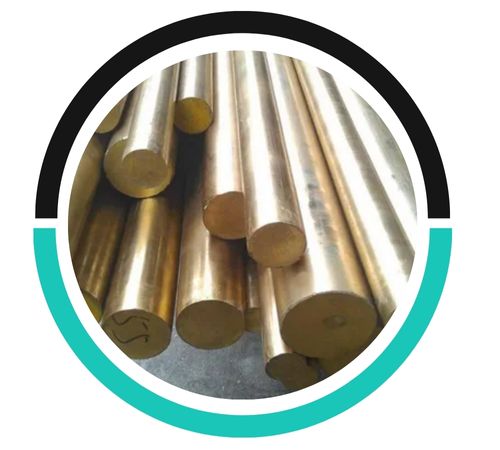

Neil Metals, located in Kolkata, India, stands out as a top-notch manufacturer and supplier of high-quality Phosphorous Bronze Bars and Rods. With a solid reputation for delivering precision-engineered non-ferrous metal products, Neil Metals caters to a diverse array of industries, ensuring that every order reflects reliability and excellence. Their phosphorous bronze offerings are crafted using cutting-edge processes that meet international standards, and they’re celebrated for their strength, durability, and resistance to corrosion. Trusted by clients nationwide, Neil Metals provides customized solutions and prompt delivery, making them a go-to partner for phosphorous bronze components across various industrial applications.

Phosphorous Bronze Bars and Rods typically consist of copper (around 89–95%), tin (4–8%), and a small amount of phosphorus (up to 0.35%). This distinctive blend boosts wear resistance, hardness, and fatigue strength. Mechanically, they boast a tensile strength of 350–550 MPa, impressive elasticity, and a Brinell hardness ranging from 70 to 150 HB, depending on the temper and alloy. They’re also recognized for their good machinability and excellent spring characteristics. These traits make phosphorous bronze perfect for precision engineering components, ensuring they perform reliably in demanding environments where strength and conductivity are crucial.

| Specifications | AMS 4625, ASTM B139, ASME SB139 |

| Phosphor Bronze Round bar size | Diameter: 3mm~800mm |

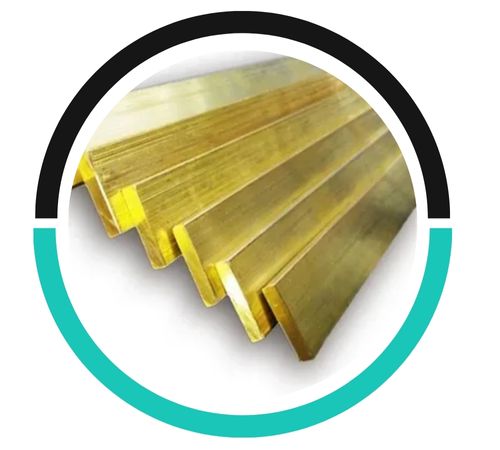

| Phosphor Bronze Angle bar size | 3mm*20mm*20mm~12mm*100mm*100mm |

| Phosphor Bronze Square bar size | 4mm*4mm~100mm*100mm |

| Phosphor Bronze Flat bar size | Thickness: 2mm~100mm |

| Width: 10mm~500mm | |

| Phosphor Bronze Hex Bar size | 2mm~100mm |

| Phosphor Bronze Billet Size | 1/2″ to 495mm Diameter |

| Phosphor Bronze Rectangles Size | 33mm x 30mm to 295mm x 1066mm |

| Finish | Bright, Polish, Bright, Rough Turned, Grinding, Centreless Ground & Black |

| Length | 1000mm-6000mm |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Surface | Hot Rolled Pickled or Sand Blasting Finished, Cold Drawn, Bright, Polished, Hairline |

| Condition | Cold Drawnd Pulished Cold Drawn Centreless Ground & Polished, Annealed round bar |

| Technique | Phosphor Bronze Hot Rolled, Cold Rolled, Cold Drawn, Forged Round Bar, Rod |

| Form | Round, Rod, Precision Ground Bar, Square, Round Rod, Hollow, Hex (A/F), Triangle, Rectangle, Threaded, T-Bar, Half Round Bar, Flat Bar, Rings, Blocks, Billet, Ingot, I/H Bar, Angle, Channel Bar, Profiles, Forging Etc. |

| Alloy number | Sn | P | Pb | Zn | Cu+Sn+P |

| C5191 | 5.5-7.0 | 0.03-0.35 | ≥99.5 | ||

| C5441 | 3.0-4.5 | 0.01-0.50 | 3.5-4.5 | 1.5-4.5 | ≥99.5 |

| Grade B.S. 1400: 1985 | Nominal Composition | 2% PS N/mm Min | Tensile Strength N/mm Min | Elongation % Min | Brinell Hardness Min |

| PB1 | 89/10/01 | 130 | 250 | 5 | 60 |

| PB1 | 88/12 | 140 | 260 | 7 | 80 |

| PB1 | 90/10 | 130 | 250 | 5 | 60 |

| PB1 | 90.5/9.5 | 130 | 240 | 5 | 80 |

| LPB-1 | 87/8/2/3 | 80 | 175 | 7 | 60 |

| Pb2 | 88/12 | 120 | 195 | 5 | 60 |

| Pb2 PB | 88/12 95/5 | 145 130 | 295 240 | 5 5 | 80 80 |

Phosphorus bronze bars can be welded, but it requires care. The material tends to be brittle at high temperatures, so preheating and using appropriate filler materials are recommended for successful welding.

To select the right phosphorous bronze bar, consider factors such as tensile strength, corrosion resistance, conductivity, the specific environmental conditions, required durability, and mechanical properties for your application.

To select the right phosphorous bronze bar, consider factors such as tensile strength, corrosion resistance, conductivity, the specific environmental conditions, required durability, and mechanical properties for your application.

Phosphorous bronze rods are available in diameters ranging from 1/8" to 12" and lengths up to 20 feet. Finishes include hot-rolled, cold-rolled, extruded, polished, and custom-machined.

Phosphorous Bronze Bars and Rods find extensive use in the electrical, automotive, marine, and industrial sectors, thanks to their outstanding mechanical and chemical properties. Their remarkable wear resistance and fatigue strength make them ideal for crafting bushings, bearings, thrust washers, connectors, and spring components. In the electrical field, they’re utilized in switchgear parts, terminals, and contact springs due to their superior conductivity and resistance to corrosion. Plus, their non-sparking and non-magnetic qualities make them suitable for use in explosive or sensitive environments, ensuring reliability and safety across a wide range of engineering applications.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved