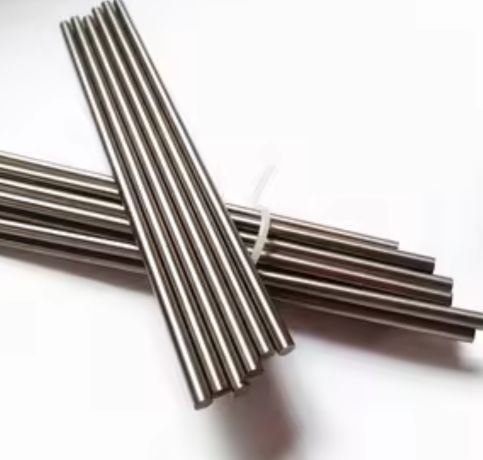

Kolkata, India-based Neil Metals produces and distributes **Nitinol shape memory bars**, providing high-quality nickel-titanium alloy solutions known for their remarkable capacity to “remember” shapes. Produced with accurate heat treatment, these bars are subjected to strict quality control to provide reliability in superelasticity, fatigue strength, and biocompatibility. Supplying key industries in medical devices, aerospace, robotics, and oil & gas, Neil Metals guarantees consistent performance under demanding conditions, backed by their knowledge, international standards compliance, and prompt delivery of tailored Nitinol solutions.

**Nitinol Shape Memory Bars** are usually made up of approximately 54.5–57% nickel and the balance titanium, together with trace quantities of oxygen and iron, forming ASTM F2063-conforming bar stock ([lintsteels.com][1]). They have a melting point of approximately 1310 °C, density of ~6.45 g/cm³, and tensile elongation of approximately 10% ([en.wikipedia.org][2]). What is most remarkable about them is the shape memory and superelastic behavior: recoverable strains of 8–10 ‰ or higher, induced by a reversible martensitic–austenitic phase transformation ([asme.org][3]). With elasticity moduli approximately 28–75 GPa depending on phase, high fatigue life, good corrosion properties, and biocompatibility, Nitinol bars are well suited for challenging dynamic applications ([asme.org][3]).

| Standards : | ASTM F2063, ASME SF2063 |

| Dimensions : | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Round bar size : | Diameter: 3-~800mm |

| Hex Bar size : | 2-100mm A/F |

| Flat bar size : | Thickness: 2 -100mm / Width: 10 to 500mm |

| Square bar size : | 4 to 100mm |

| Rectangular Bars Size : | 33 x 30mm to 295 x 1066mm |

| Hollow Bar : | 32mm OD x 16mm ID to 250mm OD x 200mm ID |

| Tolerance : | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Finish : | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

| Grade | Ni | N+O | Fe | Co | C | Nb | Cr | Cu | H | Ti |

| Nitinol | 54.5 – 57.0 | 0.050 | 0.050 | 0.050 | 0.050 | 0.025 | 0.010 | 0.010 | 0.005 | Bal |

| Element | Density | Melting Point | Elongation |

| Nickel-titanium Alloy | 6.45 g/cm3 – 0.234 lb/in3 | Around 1310 °C. | 10 % |

| STANDARD | UNS |

| NiTi Alloys | N01555 |

**Nitinol Shape Memory Bars** are applied widely in industries: in **medicine**, they create stents, guidewires, orthopedic implants, and dental archwires, utilizing their biocompatibility and superelasticity. In **aviation and automobile**, they function as actuators in morphing jet-engine chevrons, thermal valves, sensors, vibration dampers, and robotics. They are also utilized in **industrial applications**—flexible hinges, springs, pipe assembly couplings, and consumer items like flexible eyeglasses ([blog.accupathmed.com][4]). Their capacity to transform mechanical loads into accurate motion, combined with fatigue resistance and corrosion resistance, qualifies them for use in automated systems, intelligent mechanisms, and minimally invasive medical devices.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved