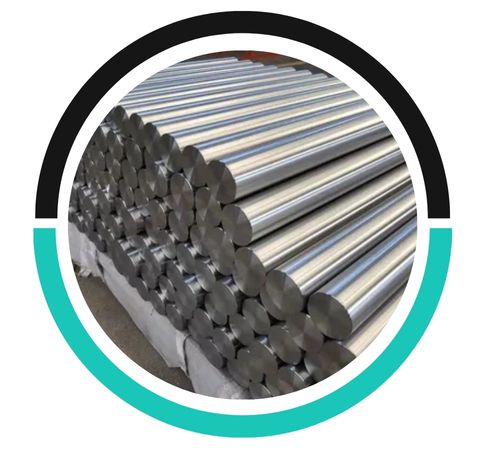

Neil Metals, located in Kolkata, India, stands out as a top manufacturer and supplier of high-performance Nimonic 86 Bars and Rods. These products are designed for industries that require exceptional heat and corrosion resistance. Engineered specifically for high-temperature and high-stress environments, these bars and rods boast impressive strength and oxidation resistance. Renowned for their durability and metallurgical stability, Neil Metals’ Nimonic 86 offerings come in various sizes and can be customized to meet global quality standards. With a commitment to precision, timely delivery, and customer satisfaction, Neil Metals has built a solid reputation both domestically and internationally.

The composition of Nimonic 86 Bars and Rods primarily includes nickel and cobalt, along with significant amounts of chromium, molybdenum, aluminum, and titanium. This unique alloy formulation provides remarkable mechanical properties, such as high tensile strength, excellent creep resistance, and reliable stress-rupture performance at temperatures reaching up to 1050°C. Typically, the tensile strength hovers around 140 ksi (965 MPa), all while ensuring outstanding structural stability and oxidation resistance. Its well-balanced composition makes it perfect for applications that require long-lasting performance under intense mechanical and thermal stress.

| Grade | Nimonic 86 – UNS |

|---|---|

| Specification | ASTM UNS |

| Standard | ASTM, ASME, API, GB, AISI, DIN, EN, SUS, UNS ASTM B166, ASTM B160, ASTM B164, ASTM B446, ASTM B637, ASTM B408, ASTM B425, ASTM B574, ASTM B335, ASTM B473, ASTM B649 |

| Nimonic 86 Round bar size | Diameter: 3mm~800mm |

| Nimonic 86 Angle bar size | 3mm*20mm*20mm~12mm*100mm*100mm |

| Nimonic 86 Square bar size | 4mm*4mm~100mm*100mm |

| Nimonic 86 Flat bar size | Thickness: 2mm~100mm |

| Width: 10mm~500mm | |

| Nimonic 86 Hex Bar size | 2mm~100mm |

| Nimonic 86 Billet Size | 1/2″ to 495mm Diameter |

| Nimonic 86 Rectangles Size | 33mm x 30mm to 295mm x 1066mm |

| LENGTHS | 12 RANDOM LENGTHS AND LONG BARS:15 20 RANDOM LENGTHS |

| Nimonic 86 Round Bar Standard Dimensions | Diameter / Height:As the customer required |

| Finish | Bright, Polish, Bright, Rough Turned, Grinding, Centreless Ground & Black |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Surface | Hot Rolled Pickled or Sand Blasting Finished, Cold Drawn, Bright, Polished, Hairline |

| Condition | Cold Drawnd Pulished Cold Drawn Centreless Ground & Polished, Annealed round bar |

| Technique | Nimonic 86 Hot Rolled, Cold Rolled, Cold Drawn, Forged Round Bar, Rod |

| Form | Round, Rod, Precision Ground Bar, Square, Round Rod, Hollow, Hex (A/F), Triangle, Rectangle, Threaded, T-Bar, Half Round Bar, Flat Bar, Rings, Blocks, Billet, Ingot, I/H Bar, Angle, Channel Bar, Profiles, Forging Etc. |

| Weight% | Ni | Cr | Mo | Ce | C |

|---|---|---|---|---|---|

| Alloy 86 | 65 | 25.0 | 10.0 | 0.03 | 0.05 max |

| Material | Treatment | Temperature °C | UltimateTensile Strength MPa | Yield Strength (0.2% Offset) MPa | Elongation on 5.65 √ 50(%) |

|---|---|---|---|---|---|

| Alloy 86 Bar | Heat Treatment 4h/1150°C/ AC | 300 | 251 | 692 | 49 |

| Allloy 86 Bar | Heat Treatment 4h/1150°C/ AC | 500 | 243 | 661 | 54 |

| Allloy 86 Bar | Heat Treatment 4h/1150°C/ AC | 700 | 239 | 557 | 56 |

| Allloy 86 Bar | Heat Treatment 4h/1150°C/ AC | 850 | 173 | 319 | 69 |

Nimonic 86 rods are available in various sizes ranging from 6mm to 100mm in diameter, with finishes including hot-rolled, cold-drawn, and polished options for enhanced surface quality.

Yes, Nimonic 86 rods can be supplied in both polished and matte finishes, depending on the supplier and specific requirements for your application or aesthetic preferences.

Nimonic 86 rods typically come in standard sizes ranging from 0.25 inches to 3 inches in diameter, with lengths varying between 3 feet to 12 feet, depending on the supplier.

Nimonic 86 Bars and Rods find extensive use in the aerospace, power generation, automotive, and chemical processing sectors. They are particularly effective in manufacturing turbine blades, combustion chambers, exhaust valves, and high-temperature fasteners. In the aerospace industry, these rods perform consistently under extreme flight conditions, while in power plants, they are utilized in components that face high pressures and temperatures. The chemical industry also benefits from their corrosion resistance in harsh environments. Thanks to their remarkable durability and resistance to thermal degradation, Nimonic 86 Bars and Rods are a reliable choice for challenging engineering applications.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved