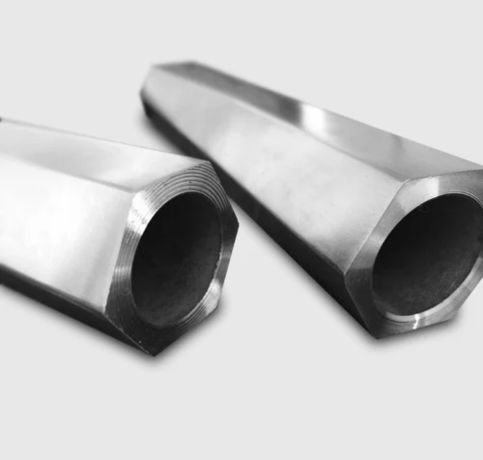

Neil Metals is a reliable producer and supplier of Monel Hollow Bars, based in Kolkata, India. Known for high-grade nickel-copper alloys, Neil Metals provides precision-engineered Monel solutions that work with consistency in harsh and stressful conditions. Monel Hollow Bars are produced through sophisticated metallurgical processes to achieve superior dimensional accuracy, strength, and corrosion resistance. Industrial sectors like marine engineering, oil & gas, chemical processing, and defense are served by Neil Metals with tailor-made solutions to satisfy various industrial requirements. Prioritizing quality, service, and punctual delivery, the company is an entrenched favourite as a prime supplier of high-quality hollow bar stock.

Monel Hollow Bars are generally manufactured using Monel 400 or Monel K500 alloys. Monel 400 is about 63% nickel and 30–34% copper with residual amounts of iron, manganese, and silicon and is noted for its excellent corrosion resistance and good mechanical strength. Monel K500 introduces aluminum and titanium, which gives it greater tensile and yield strength with the same corrosion resistance. Mechanical properties vary between 550–860 MPa tensile strength and 170–690 MPa yield strength based on grade and condition. Monel Hollow Bars come in different outer and inner diameters and wall thicknesses to suit the needs of particular applications.

| Specifications | : | ASTM B164 / ASTM SB164 |

| Dimensions | : | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Size | : | 5 mm To 500 mm |

| Diameter | : | 0.1 mm to 100 mm |

| Length | : | 100 mm To 3000 mm Long & Above |

| Finish | : | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

| Tolerance | : | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Form | : | Hollow |

| Designation | C% | Co% | Cr% | Mo% | Ni% | V% | W% | Ai% | Cu% | Nb/Cb Ta% | Ti% | Fe% | Sonstige Autres-Other % |

| – | 0.12 | – | – | – | 65.0 | – | – | – | 32.0 | – | – | 1.5 | Mn 1.0 |

| – | 0.10 | – | – | – | 43.0 | – | – | – | 53.0 | – | – | 0.75 | Si 0.25; Mn 2.25 |

| – | 0.15 | – | 52.0-57.0 | – | – | 0.05 | rest/bal | – | – | 0.50 | Mn 0.10; Si 0.10;S o.024 | ||

| – | 0.10 | – | – | – | 63.0-17.0 | – | – | 2.5-3.5 | rest/bal | – | 0.50 | 2.0 | Mn 1.5;Si 0.5; S 0.010 |

| – | 0.13 | – | – | – | 64.0 | – | – | 2.8 | 30.0 | – | 0.6 | 1.0 | Mn 0.8 |

| – | 0.15 | – | – | – | 66.0 | – | – | – | 31.0 | – | – | 1.2 | Mn 1.0; S 0.04 |

| Element | Monel |

| Density | 8.8 g/cm3 |

| Melting Point | 1350 °C (2460 °F) |

| Tensile Strength | Psi – 80,000 , MPa – 550 |

| Yield Strength (0.2%Offset) | Psi – 35,000 , MPa – 240 |

| Elongation | 40 % |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved