Neil Metals, based in Kolkata, India, has built a solid reputation as a manufacturer and supplier of top-notch Molybdenum Bars and Rods. They cater to a variety of industries that demand exceptional strength and heat resistance. With a strong emphasis on precision and durability, Neil Metals provides molybdenum products that adhere to strict global standards. These bars and rods are perfect for tough environments, thanks to their high melting point, impressive thermal conductivity, and resistance to corrosion and creep. With state-of-the-art production capabilities and a dedication to customer satisfaction, Neil Metals guarantees consistent quality and timely delivery of their molybdenum products for both industrial and technological uses.

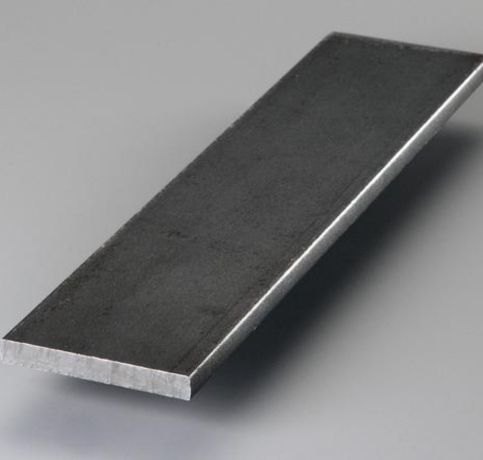

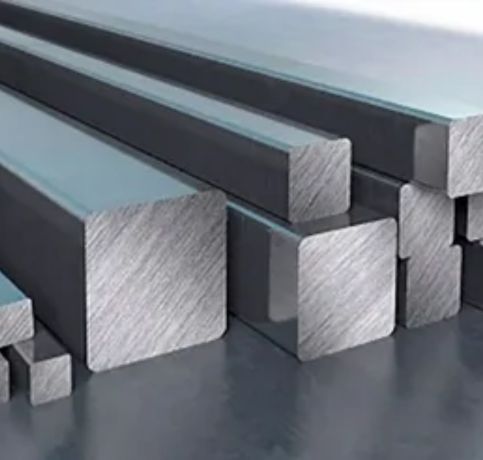

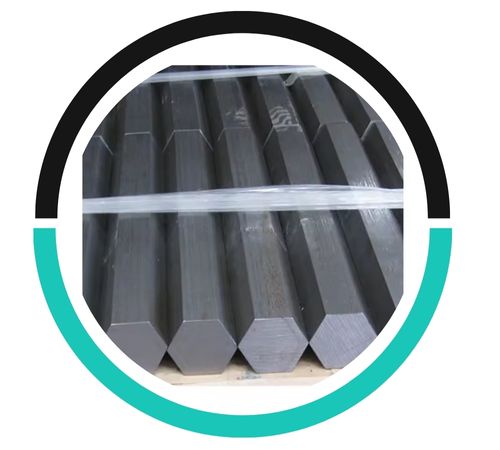

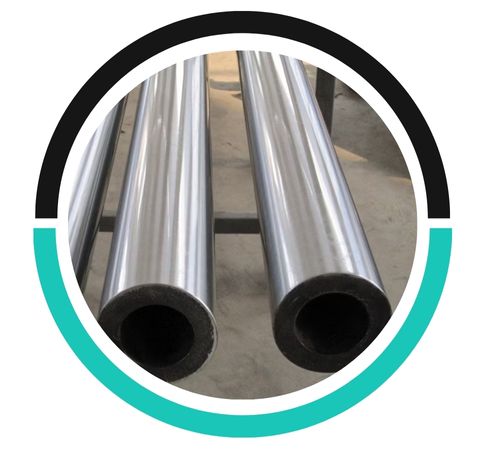

Molybdenum Bars and Rods are primarily made of pure molybdenum, boasting a minimum content of 99.95%. This refractory metal is celebrated for its high melting point (2623°C), low thermal expansion coefficient, and good electrical conductivity. In terms of mechanics, these bars and rods have a tensile strength of around 620 MPa, excellent dimensional stability even under extreme heat, and remarkable creep resistance. These characteristics make them ideal for high-temperature structural applications and processes that involve thermal cycling, all while maintaining their shape and integrity under stress.

| Product | Molybdenum Rod |

|---|---|

| Standard | ASTM B387, Type 361/364 |

| Process | Drawing, swaging |

| Purity | Mo≥99.95% |

| Size | 0.16”~6.0” diameter x L |

| Surface | Grinding, Finish turning, Black Oxide, Chemically clneaned |

| Grade | The impurity content is not more than % | |||||||

| Fe | Ni | Al | Si | Mg | C | N | O | |

| Mo-1 | 0.01 | 0.005 | 0.002 | 0.01 | 0.005 | 0.01 | 0.003 | 0.008 |

| Mo-2 | 0.01 | 0.005 | 0.005 | 0.01 | 0.005 | 0.01 | 0.003 | 0.02 |

| Tensile Strength | KSI (Mpa)-RT | 110 (760) |

| KSI (Mpa)-500°C | — | |

| KSI (Mpa)-1000°C | — | |

| Elongation | % in 1.0″. | 15 |

| Hardness | DPH | 220 |

Yes, molybdenum bars can be welded, but they require special techniques due to their high melting point. Proper care, such as using appropriate filler materials and preheating, is essential.

Molybdenum rods are generally resistant to galvanic corrosion due to their excellent corrosion resistance. However, in certain environments, especially when paired with more anodic metals, galvanic corrosion can still occur.

You’ll find Molybdenum Bars and Rods in a variety of industries, including aerospace, electronics, nuclear energy, and metallurgy. They play a crucial role in creating high-temperature furnace components, heat shields, and support structures due to their thermal and mechanical stability. In the electronics field, they are essential components in semiconductor devices and sputtering targets. Molybdenum also finds its way into medical and defense applications, as well as in glass manufacturing and chemical processing, where resistance to chemical corrosion and structural performance under high heat are vital.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved