Neil Metals is a leading Indian manufacturer and supplier of **Inconel X-750 Bars and Rods**, providing precision-crafted superalloy components for demanding high-performance applications. Leveraging the latest manufacturing and rigorous quality control processes in accordance with ASTM B637, AMS, ASME, and ISO specifications, Neil Metals provides superior dimensional quality, corrosion resistance, and elevated temperature strength. Their technical expertise serves industries like aerospace, nuclear, petrochemical, and power generation, in which parts face extreme stress and temperature. With technically sound pricing, competitive pricing, and guaranteed delivery, Neil Metals emerges as the reliable partner for Inconel X‑750 inventory.

**Inconel X-750 Bars and Rods** (UNS N07750) are nickel-chromium superalloy material with a minimum 70% nickel, 14–17% chromium, 2.25–2.75% titanium, 0.4–1.0% aluminum, and 0.7–1.2% niobium + tantalum, iron 5–9%, trace elements (C ≤ 0.08%, Mn ≤ 1%, Si ≤ 0.5%, Co ≤ 1%) ([aircraftmaterials.com][1]). They are strengthened through precipitation hardening, resulting in room-temperature mechanical properties of tensile strength ~1267 MPa, yield strength ~868 MPa, and elongation ~25% ([robustspecialmetals.com][2]). These bars have very good creep, fatigue, and relaxation resistance up to ~650 °C, tensile strength in excess of 1000 MPa at elevated temperatures.

Specification : ASTM B 637 / ASME SB 637, AMS 5669, AMS 5698, AMS 5699

Dimensions : ASTM, ASME and API

Size : 5 mm To 500 mm

Diameter : 0.1 mm to 100 mm

Length : 100 mm To 3000 mm Long & Above

Finish : Bright, Polish & Black

Grade : Inconel X-750 – UNS N07750

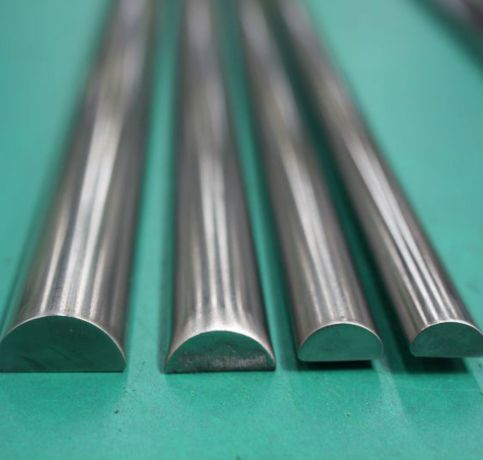

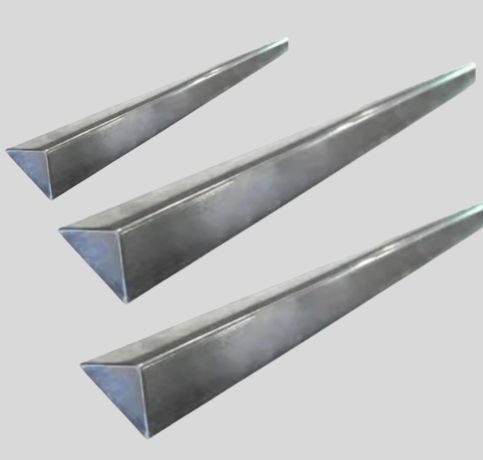

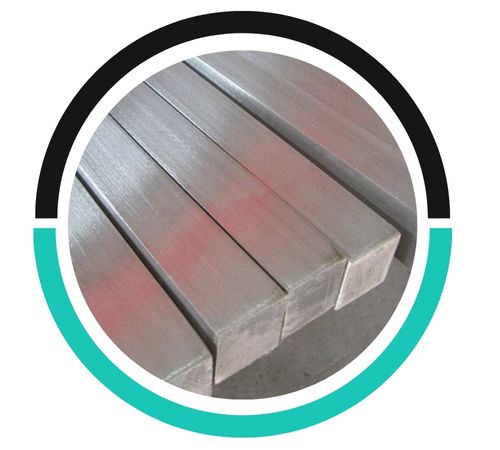

Form : Round, Square, Hex (A/F), Rectangle, Wire (Coil Form), Wire-mesh, Billet, Ingot, Forging Etc.

Our Inconel X-750 Round Bars conforms to NACE MR0175/ISO 15156

| Grade | Ni | Cr | Al | C | Mn | Ti | Cu | Si | S |

| Inconel X-750 | 70.0 min | 14.0 – 17.0 | 0.40 – 1.0 | .08 max | 1.00 max | 2.25 – 2.75 | 0.50 max | .50 max | .01 max |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.28 g/cm3 | 1430°C | 1267 MPa | 868 MPa | 25 % |

| STANDARD | WERKSTOFF NR. | UNS |

| Inconel X750 | 2.4669 | N07750 |

| Temperature, °F | Mean Linear Expansion, in./in./°F x 10-6 from 70° F to Temperature Shown | Thermal Conductivity, Btu/in./hr/sq ft/°F | Specific Heat Btu/lb/°F | Diffusivity, sq ft/hr | Electrical Resistivity, ohm/circ mil/ft |

|---|---|---|---|---|---|

| -100 | 6.7 | 74 | 0.090 | 0.135 | – |

| 70 | – | 83 | 0.103 | 0.132 | 731 |

| -250 | 6.5 | 67 | 0.073 | 0.150 | – |

| -200 | 6.6 | 70 | 0.080 | 0.143 | – |

| 600 | 7.5 | 109 | 0.120 | 0.148 | 761 |

| 800 | 7.8 | 120 | 0.125 | 0.158 | 771 |

| 200 | 7.0 | 89 | 0.109 | 0.133 | 739 |

| 400 | 7.2 | 98 | 0.116 | 0.140 | 746 |

| 1000 | 8.1 | 131 | 0.130 | 0.169 | 783 |

| 1600 | 9.3 | 164 | 0.171 | 0.164 | 761 |

| 1800 | 9.8 | – | – | – | – |

| 1200 | 8.4 | 143 | 0.137 | 0.173 | 786 |

| 1400 | 8.8 | 154 | 0.151 | 0.172 | 775 |

**Inconel X-750 Bars and Rods** have wide application for **high-temperature springs, bolting, and fasteners** in rocket engines, nuclear reactors, and gas turbines because of their high relaxation and creep resistance. They are used in **pressure vessels, aircraft components, and ducting systems**, where high strength and resistance to oxidation up to 700 °C are required ([aircraftmaterials.com][1]). They also find applications in **forming dies, extrusion dies, thrust chambers**, and high-temperature power generation equipment like burner nozzles and heat exchanger parts. Their successful use in corrosive and oxidative environments makes them a first preference for severe mechanical and structural applications.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved