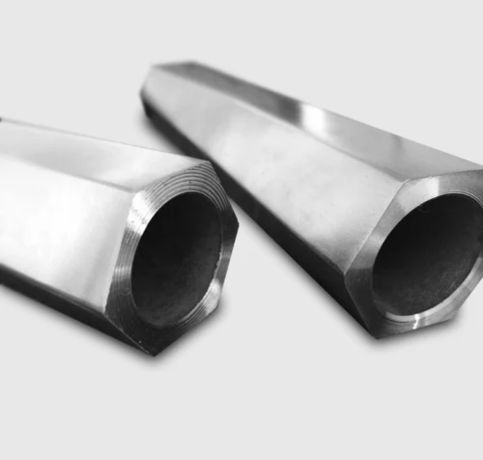

Neil Metals stands out as a leading manufacturer and supplier of Inconel Hollow Bars, proudly based in Kolkata, India. Known for their top-notch nickel alloy products, Neil Metals specializes in precision-engineered Inconel hollow bars that boast exceptional strength, heat resistance, and corrosion resistance. These bars are perfect for high-temperature and high-stress environments, making them ideal for industries like chemical processing, aerospace, marine, and power generation. With a commitment to advanced technology and rigorous quality control, Neil Metals guarantees that each product meets international standards. Their focus on performance, durability, and timely delivery has made them a trusted name in the specialty alloys market.

Inconel hollow bars are crafted from high-performance nickel-chromium-based alloys, mainly Inconel 600, 625, or 718. These alloys typically consist of about 58% nickel, 20–23% chromium, along with varying amounts of molybdenum, iron, and niobium depending on the specific grade. Inconel bars are known for their impressive mechanical strength, with tensile strength ranging from 750 MPa to over 1300 MPa, and they exhibit high creep resistance even at elevated temperatures. They maintain their structural integrity in extreme conditions and resist oxidation, carburization, and chloride-induced stress corrosion cracking. Plus, their hollow design helps reduce weight and material usage in certain structural or fluid-handling applications.

| Ni | Cr | Fe | Mo | Nb+Ta | C | Mn | Si | Ph | S | Al | Ti | Co | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min | Bal | 20 | – | 8 | 3.15 | – | – | – | – | – | – | – | – |

| Max | – | 23 | 5 | 10 | 4.15 | 0.10 | 0.50 | 0.50 | 0.015 | 0.015 | 0.40 | 0.40 | 1.0 |

| 0.2% Proof Stress | Tensile Strength | Elongation | Reduction of area | Hardness |

|---|---|---|---|---|

| MPA | MPA | % | % | HRB |

| Min | Min | Min | Min | Min |

| 414 | 827 | 30 | 40 | 145 |

Inconel Hollow Bars find extensive use in industries that require high-temperature strength, corrosion resistance, and durability under harsh conditions. This includes the aerospace sector for components like exhaust ducts, turbine blades, and rocket motors; the chemical and petrochemical industries for heat exchangers, reactors, and piping; and the marine industry for components exposed to saltwater. They are also utilized in nuclear reactors, oil and gas drilling tools, and high-performance automotive parts. The hollow design not only enhances material efficiency but also reduces weight and simplifies machining, making Inconel hollow bars a smart choice for various applications.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved