Neil Metals, based in Kolkata, India, is a prime manufacturer and supplier of **Inconel 783 Bars/Rods**, which are high-performance superalloy products designed for challenging aerospace, power generation, and high-temperature industrial applications. Precision manufacturing and stringent quality control are characteristics of Neil Metals that supply Inconel 783 bars with outstanding oxidation resistance, high-temperature strength, and dimensional stability. These bars are designed to satisfy industries demanding exceptional performance in harsh thermal and corrosive conditions. Through sophisticated manufacturing capabilities and customer-oriented production, Neil Metals provides secure delivery and consistent quality for high-pressure engineering parts.

**Inconel 783 Bars/Rods** are nickel-cobalt-iron superalloys with an almost **39% Nickel**, **25% Iron**, **20% Cobalt**, and additions of **up to 15% Chromium**, **Niobium**, **Titanium**, and **Aluminum**. This alloy is formulated for superior **oxidation and creep resistance** together with **low thermal expansion**. The common mechanical properties are **tensile strength over 900 MPa**, **yield strength in excess of 700 MPa**, and **improved fatigue resistance** at high temperatures. Inconel 783 has structural stability in temperatures above **700°C**, so it is suitable for precision components subjected to thermal cycling and mechanical loading.

| Dimensions | ASTM, ASME and API |

| Size | 5 mm to 500 mm |

| Diameter | 0.1 mm to 100 mm |

| Grade | Inconel 783 – UNS R30783 |

| Finish | Bright, Polish & Black |

| Length | 100 mm To 3000 mm Long & Above |

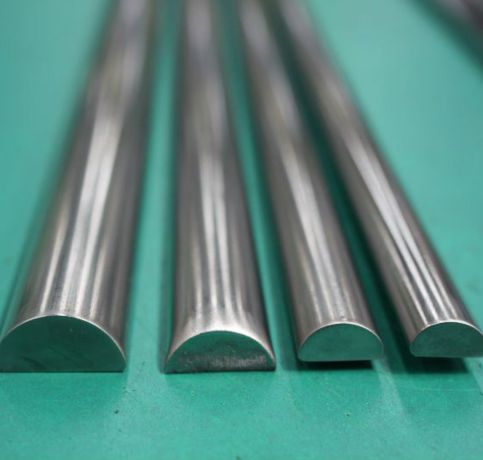

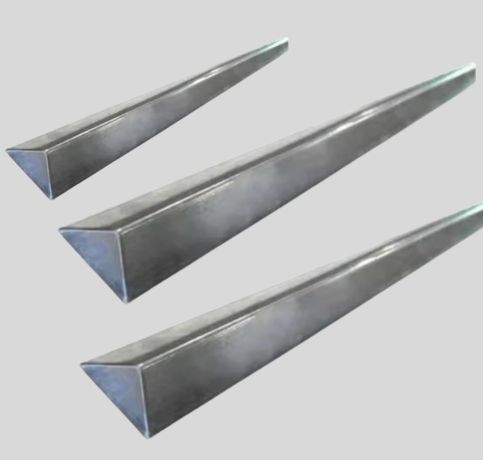

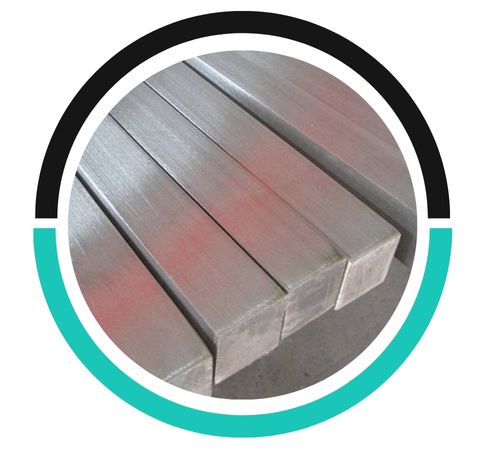

| Form | Round, Square, Hex (A/F), Rectangle, Wire (Coil Form), Wire-mesh, Billet, Ingot, Forging Etc. |

| Grade | C | Mn | Si | Cu | S | Al | Ti | Ni | Cr |

| Inconel 783 | 0.03 max | 0.05 max | 0.50 max | 0.50 max | 0.05 max | 5-6 | 0.1 – 0.4 | 26-30% | 2.5 – 3.5 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.81 g/cm3 | 1407°C | 1194 MPa | 779 MPa | 24 % |

Density |

7.7-8.03 g/cm3 |

Melting point |

1338-1380 ℃ |

Hardess |

HB335 |

**Inconel 783 Bars/Rods** find applications in **aerospace engine parts, gas turbine casings, afterburner components, exhaust systems, and high-temperature fasteners** where there is a need for oxidation resistance and thermal stability. As the alloy has **low coefficient of thermal expansion**, it is highly suitable for **tight-tolerance aerospace and turbine components** that require to maintain their dimensions despite harsh heat. Inconel 783 is also used in **nuclear, marine, and power generation applications** where high temperature, oxidation, and mechanical loading performance is essential. Its balanced properties render it a choice for parts working in thermally and chemically aggressive environments.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved