Neil Metals, located in Kolkata, India, is a well-known manufacturer and supplier of high-performance Inconel 738 Bars and Rods. They cater to industries that operate in tough thermal and mechanical conditions. With a solid reputation for precision engineering, Neil Metals creates Inconel 738 products that boast impressive creep strength, oxidation resistance, and structural stability even at high temperatures. These bars and rods are specifically designed for critical applications in aerospace, gas turbines, and power generation. Neil Metals is committed to delivering consistent quality, adhering to global standards, and ensuring timely delivery to both domestic and international markets.

Inconel 738 is a nickel-based superalloy, primarily made up of about 60% Nickel, 16% Chromium, 8.5% Cobalt, 3.4% Titanium, 3.4% Aluminum, along with Tungsten, Molybdenum, and trace amounts of Carbon, Boron, and Zirconium. This precipitation-hardened alloy is crafted for high-temperature strength and oxidation resistance. Inconel 738 Bars and Rods demonstrate high tensile strength, typically exceeding 1000 MPa, exceptional creep resistance, and maintain their mechanical stability at temperatures reaching up to 980°C. The alloy is generally used in cast form and is enhanced by gamma prime (γ’) precipitates.

Specification : ASTM B 166 / ASME SB 166

Dimensions : ASTM, ASME and API

Size : 5 mm To 500 mm Dia in 100 mm TO 6000 mm Length available with NACE MR 01-75.

Length : 100 mm To 3000 mm Long & Above

Finish : Bright, Polish & Black

Grade : Inconel 738 – UNS N07738

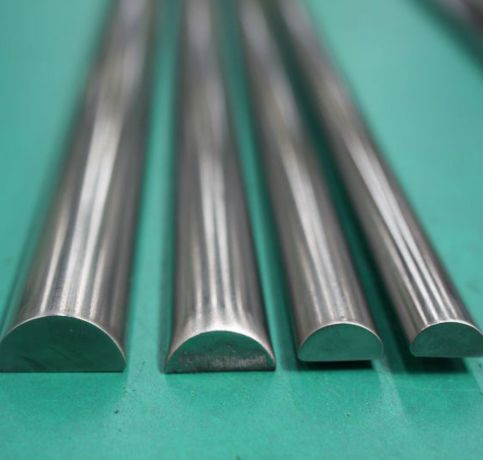

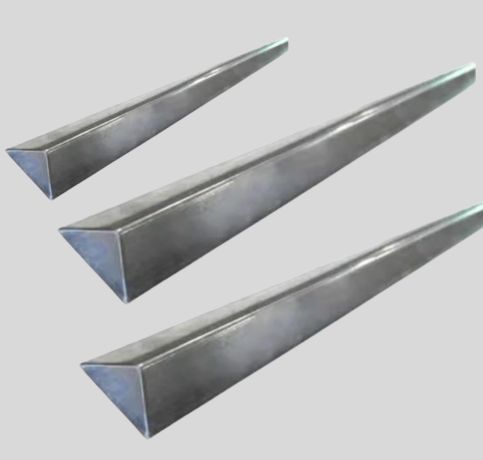

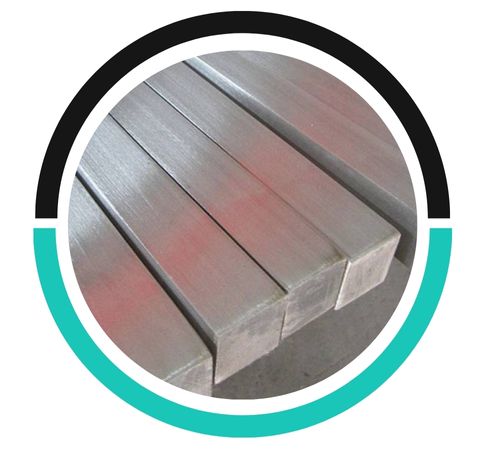

Form : Round, Square, Hex (A/F), Rectangle, Wire (Coil Form), Wire-mesh, Billet, Ingot, Forging Etc.

Our Inconel 738 Round Bars conforms to NACE MR0175/ISO 15156

| Appearance | Metallic powder or solid in various forms |

|---|---|

| Melting Point | 1230-1315 °C |

| Boiling Point | N/A |

| Density | 8.11 g/cm3 |

| Solubility in H2O | N/A |

| Specific Heat | 0.10 Btu/lb/° F (70 ° F) |

| Tensile Strength | 159000 psi (70 °F) |

| Thermal Conductivity | 82 Btu/ft2/in/hr/°F (400 °F) |

| Thermal Expansion | 6.45 x 10-6 (70-200 °F) |

Inconel 738 bars and rods are not typically used in cryogenic applications, as their properties are optimized for high-temperature environments. For cryogenic conditions, alloys specifically designed for low temperatures are preferred.

To choose the right Inconel 738 bars and rods, consider factors such as temperature requirements, corrosion resistance, mechanical strength, specific application needs, and compatibility with other materials in the operating environment.

Yes, Inconel 738 bars and rods should undergo regular inspection, especially in high-stress and high-temperature applications, to ensure they maintain their structural integrity and performance over time.

These Inconel 738 Bars and Rods find extensive use in aerospace and industrial gas turbine engines, especially in hot section components like turbine blades, nozzles, and combustion hardware. They’re also utilized in power plants, particularly in high-efficiency, high-temperature turbine systems. Thanks to their outstanding thermal fatigue and oxidation resistance, these bars are perfect for applications that demand long-term stability under cyclic loading. Additionally, they are used in components for heat treatment equipment, high-performance exhaust systems, and high-temperature tooling where superior strength and resistance to thermal degradation are crucial.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved