Neil Metals, established in Kolkata, India, is a well-known producer and distributor of **Inconel 722 Bars/Rods**, offering world-class nickel alloy solutions for extremely demanding and high-temperature industrial applications. Popular for its quality and reliable service, Neil Metals manufactures Inconel 722 bars with unmatched strength, corrosion resistance, and stability in extreme conditions. These bars are produced under sophisticated metallurgical operations and are perfectly suitable for serious industries such as aerospace, nuclear, marine, and chemical processing. With a prime emphasis on performance and toughness, Neil Metals ensures every product to international standards and customized to the most stringent application requirements.

**Inconel 722 Bars/Rods** are precipitation-hardenable, high-strength nickel-chromium alloys with **around 55% Nickel**, **14–17% Chromium**, **7–9% Iron**, and with added **Titanium, Aluminum, and Niobium** to provide strength and heat stability. They possess excellent mechanical properties with **tensile strength greater than 1000 MPa**, **yield strength greater than 800 MPa**, and **impressive creep resistance**. They have their integrity intact even at high temperatures and are immune to oxidation, chloride-induced stress corrosion cracking, and general corrosion in oxidizing or acidic environments, making them suitable for severe service conditions.

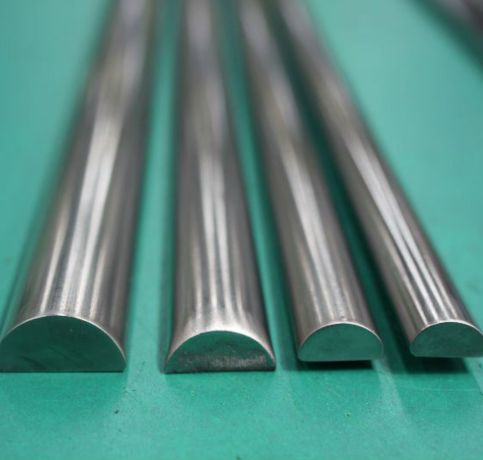

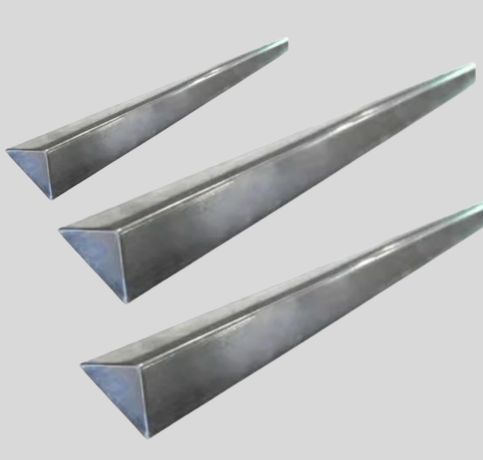

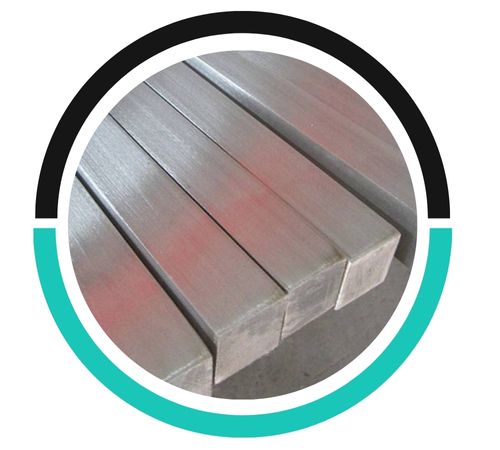

| Type: | Round | Application: | Construction,Industry,Mechineal |

|---|---|---|---|

| Standard: | DIN,ASTM,AISI,JIS,EN | Grade: | Inconel738 LC |

| Shape: | Round | Certification: | ISO,BV,SGS |

| Dimensions: | 5.5mm-500mm | Surface: | Bright, Polished, black |

| Technique: | Cold Drawn & hot Rolled | Packing: | Standard Seaworthy Package |

| Price Term: | – | – | – |

Carbon: 0.15-0.20

Cobalt: 8.00-9.00

Chromium: 15.70-16.30

Molybdenum: 1.50-2.00

Tungsten: 2.40-2.80

Tantalum: 1.50-2.00

Columbium: 0.60-1.10

Aluminum: 3.20-3.70

Titanium: 3.20-3.70

Aluminum+Titanium: 6.50-7.20

Boron: 0.005-0.015

Zirconium: 0.05-0.15

Iron: 0.50 max

Manganese: 0.20 max

Silicon: 0.30 max

Sulfur: 0.015 max

| Appearance | Metallic powder or solid in various forms |

|---|---|

| Melting Point | 1230-1315 °C |

| Boiling Point | N/A |

| Density | 8.11 g/cm3 |

| Solubility in H2O | N/A |

| Specific Heat | 0.10 Btu/lb/° F (70 ° F) |

| Tensile Strength | 159000 psi (70 °F) |

| Thermal Conductivity | 82 Btu/ft2/in/hr/°F (400 °F) |

| Thermal Expansion | 6.45 x 10-6 (70-200 °F) |

**Inconel 722 Bars/Rods** find extensive use in applications where there is a requirement for high strength, corrosion resistance, and thermal stability. Some common applications include **aerospace parts, jet engine components, turbine blades, fasteners used at high temperature, pressure vessels, valves**, and **chemical processing equipment**. They are also used in **nuclear reactors**, **marine engineering**, and **oil and gas exploration equipment**, where exposure to hostile media and high pressures is typical. The cyclic heating resistance and resistance of Inconel 722 to oxidation as well as fatigue make it an ideal material for parts working in harsh mechanical as well as thermal conditions.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved