Neil Metals is a reputable manufacturer and supplier of top-quality Inconel 718 Bars and Rods, proudly based in Kolkata, India. Known for their commitment to quality and precision, Neil Metals provides high-performance nickel-based alloy products that excel in extreme conditions. Inconel 718 is a superalloy that hardens through precipitation, celebrated for its remarkable strength, resistance to corrosion, and ability to endure high temperatures and pressures. The company caters to vital industries such as aerospace, power generation, oil & gas, and chemical processing. With cutting-edge manufacturing techniques and rigorous quality controls, Neil Metals guarantees that its Inconel 718 bars and rods comply with global standards and meet specific customer needs.

Inconel 718 Bars and Rods consist of about 50–55% Nickel, 17–21% Chromium, 4.75–5.5% Niobium + Tantalum, 2.8–3.3% Molybdenum, 0.65–1.15% Titanium, along with trace amounts of Aluminum, Iron, and Cobalt. This alloy boasts impressive mechanical properties, achieving tensile strength up to 1240 MPa and yield strength around 1035 MPa after heat treatment. It retains high strength and toughness even at temperatures reaching 700°C. Inconel 718 also showcases exceptional fatigue resistance, stress corrosion cracking resistance, and creep-rupture strength, making it ideal for high-stress environments.

| Specifications | ASTM B116 / ASTM SB116 |

| Dimensions | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Size | 5 mm to 500 mm |

| Diameter | 0.1 mm to 100 mm |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Finish | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

| Length | 100 mm To 3000 mm Long & Above |

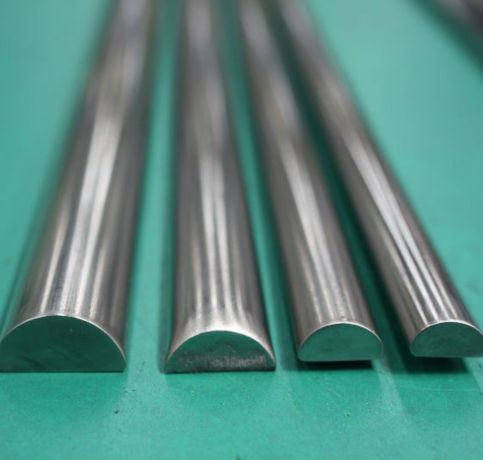

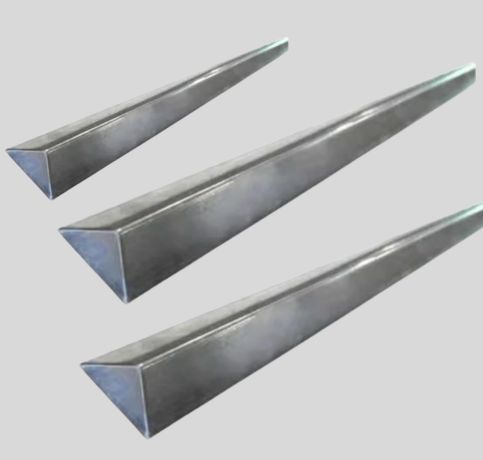

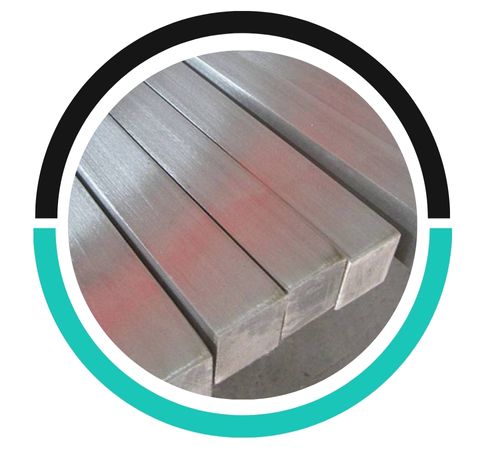

| Form | Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc. |

| Grade | C | Mn | Si | Cu | S | Fe | Mo | Ni | Cr |

| Inconel 718 | 0.08 max | 0.35 max | 0.35 max | 0.30 max | 0.15 min | – | – | 50 – 55 | 17 – 21 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.2 g/cm3 | 1350 °C (2460 °F) | Psi – 1,35,000 , MPa – 930 | Psi – 75,000 , MPa – 482 | 45 % |

Density | 8.2 g/cm³ |

Melting point | 1260-1340 ℃ |

Inconel 718 Bars and Rods find extensive applications in industries that demand high strength and corrosion resistance at elevated temperatures. In aerospace, they are crucial for components like jet engine parts, turbine blades, fasteners, and rocket motors. The oil & gas sector utilizes them in downhole equipment, wellhead components, and tools that face high pressures and corrosive conditions. In power generation, Inconel 718 is relied upon for heat exchangers, boiler components, and nuclear reactors. Its outstanding mechanical performance also makes it a great fit for high-performance automotive parts.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved