Neil Metals, located in Kolkata, India, has earned a solid reputation as a reliable manufacturer and supplier of Inconel 713C Bars and Rods. These high-performance nickel-based superalloys are specifically designed for extreme-temperature applications. With a keen emphasis on metallurgical precision and adherence to global quality standards, Neil Metals serves various industries, including aerospace, power generation, and high-temperature processing. Their Inconel 713C products are built to endure thermal stress, oxidation, and creep, making them perfect for critical components. Neil Metals prides itself on timely deliveries, exceptional dimensional accuracy, and consistent performance, establishing itself as a go-to supplier for Inconel 713C bars and rods in demanding environments.

Inconel 713C Bars and Rods are made from a nickel-chromium base alloy, enhanced with aluminum, titanium, molybdenum, and carbon. This precipitation-hardened alloy boasts impressive strength and oxidation resistance at temperatures reaching up to 980°C. Typically, it consists of about 75% nickel, 13% chromium, 6% aluminum, 1.5% titanium, and 4.5% molybdenum. With a tensile strength of around 965 MPa, it exhibits high creep resistance, making it ideal for situations that involve prolonged exposure to heat and stress. Inconel 713C maintains its structural integrity even under thermal cycling and in corrosive environments.

Specification : ASTM B 166 / ASME SB 166

Dimensions : ASTM, ASME and API

Size : 5 mm To 500 mm Dia in 100 mm TO 6000 mm Length available with NACE MR 01-75.

Length : 100 mm To 3000 mm Long & Above

Finish : Bright, Polish & Black

Grade : Inconel 713C – UNS N07713

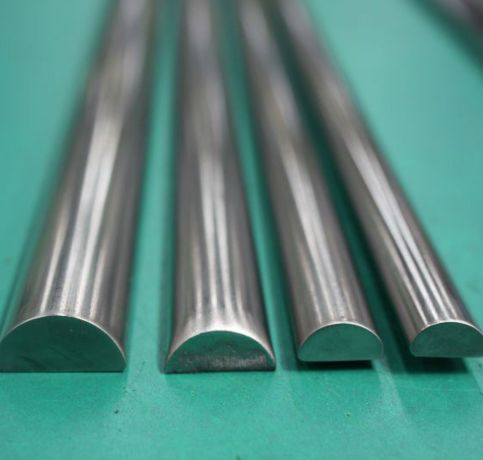

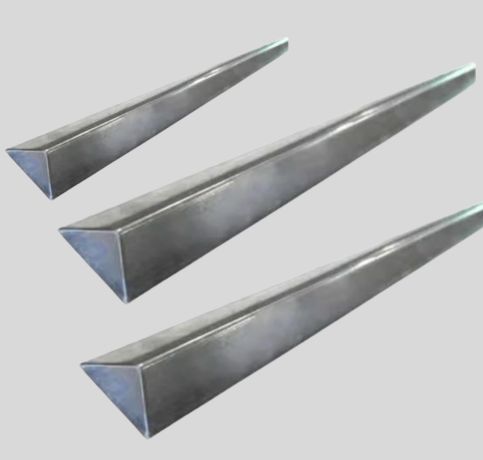

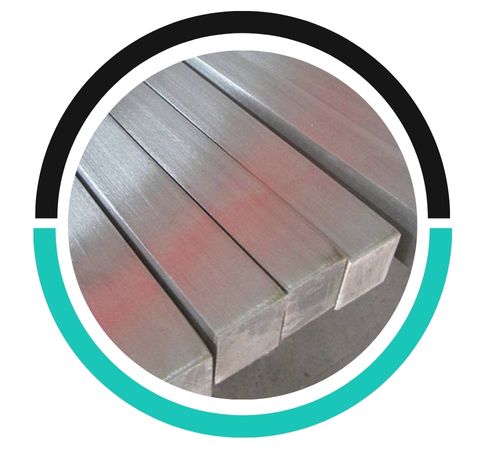

Form : Round, Square, Hex (A/F), Rectangle, Wire (Coil Form), Wire-mesh, Billet, Ingot, Forging Etc.

Our Inconel 713C Round Bars conforms to NACE MR0175/ISO 15156

| Element | Inconel 713C |

| Ni | 72.0 min |

| C | 0.15 max |

| Mn | 1.0 max |

| Cu | 0.5 max |

| S | 0.015 max |

| Si | 0.5 max |

| Cr | 14.0 – 17.0 |

| Fe | 6.0 – 10.0 |

| Element | Inconel 713C |

| Density | 1413 °C (2580 °F) |

| Melting Point | 1413 °C (2580 °F) |

| Tensile Strength | Psi – 95,000 , MPa – 655 |

| Yield Strength (0.2%Offset) | Psi – 45,000 , MPa – 310 |

| Elongation | 40 % |

| Hardness (Brinell) | – |

Yes, Inconel 713C bars/rods can withstand high temperatures due to their excellent heat resistance and ability to maintain strength in extreme thermal environments.

Yes, Inconel 713C bars and rods are customizable, offering options in dimensions, finishes, and tolerances to meet specific application and industry requirements. For more details mail us on sales@neilmetals.co.in

Yes, Inconel 713C bars and rods offer exceptional corrosion resistance, especially against oxidation and high-temperature environments, making them suitable for critical industrial applications.

These Inconel 713C Bars and Rods find their primary application in high-temperature aerospace and turbine settings, including critical components like turbine blades, vanes, and combustion liners. Their outstanding heat and oxidation resistance make them perfect for industrial gas turbines, turbochargers, and hardware used in power plants. Additionally, they are utilized in heat treatment fixtures, furnace components, and automotive exhaust systems that face continuous thermal and mechanical loads. The alloy’s mechanical strength and resistance to scaling are vital for applications where reliability under heat and stress is crucial.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved