Neil Metals, located in Kolkata, India, has built a solid reputation as a manufacturer and supplier of top-notch Inconel 602 Bars and Rods. They specialize in providing advanced material solutions designed to thrive in high-temperature and highly corrosive environments. Known for their precision engineering and dependable performance, Neil Metals adheres to international standards and caters to critical industries like aerospace, thermal processing, power generation, and petrochemicals. With cutting-edge infrastructure, tailored product offerings, and a rigorous quality assurance process, Neil Metals guarantees timely delivery and consistent excellence, making them a go-to partner for industries in need of durable, heat-resistant, and corrosion-resistant materials like Inconel 602 Bars and Rods.

Inconel 602 Bars and Rods are primarily made up of nickel (up to 63%), with notable amounts of chromium (around 25%), iron, aluminum, and trace elements such as titanium and yttrium. This distinctive blend gives them remarkable oxidation resistance at temperatures over 1100°C. These bars boast impressive mechanical properties, featuring a tensile strength ranging from 620 to 870 MPa and good creep rupture strength. Inconel 602 is celebrated for its excellent thermal fatigue resistance, superior scale adhesion, and structural stability during extreme thermal cycling, making it a top pick for demanding and high-temperature industrial settings.

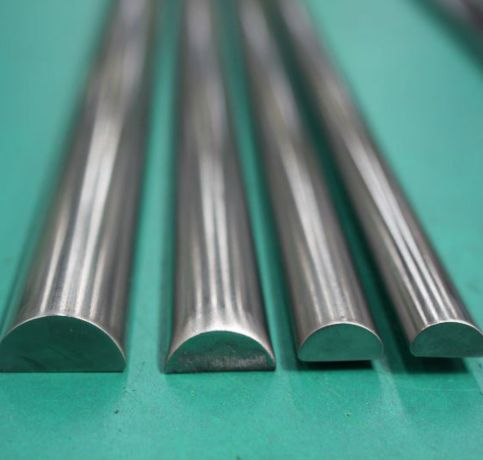

Standard: ASTM B163-04 Seamless Inconel Bars and Rods

Steel Grade: 602 N06025 2.4633 Nicrofer 6025HT(VDM)

Size Range:

OD: 6-219mm, Wall Thickness: 1.0-15mm

Chemcial Composition(%): Unless specified in the table, numerical value presents maximum

| Grade (UNS) | C | Si | Mn | S | Cr | Ni | Fe |

| N06025 | 0.15-0.25 | 0.50 | 0.50 | 0.01 | 24.0-26.0 | Bal. | 8.0-11.0 |

| Finish Condition | Tensile Strength (KsiMpa) Min | Yield Strength (Ksi/Mpa) Min | Elongation (%) Min |

| Annealed | 98Ksi/680Mpa | 39Ksi/270Mpa | 30% |

Yes, Inconel 602 bars and rods are specifically designed for high-temperature applications. They offer excellent resistance to oxidation and maintain their strength and stability in extreme heat environments, making them ideal for industrial use.

Yes, Inconel 602 bars and rods can be recycled. Their high nickel and chromium content makes them suitable for reuse in various industrial processes, promoting sustainability and reducing waste.

Yes, Inconel 602 bars and rods should undergo regular inspection, especially in high-stress and high-temperature applications, to ensure their structural integrity and optimal performance over time.

Inconel 602 Bars and Rods find extensive use in applications that require exceptional high-temperature oxidation resistance and mechanical strength. In the aerospace industry, they are perfect for components in gas turbines, jet engines, and heat shields. Thermal processing sectors utilize them in furnace hardware, radiant tubes, and muffles, thanks to their ability to endure cyclic heating and corrosive environments. In power generation and petrochemical industries, these bars are employed in reformers, flare tips, and high-temperature reactors. Their outstanding resistance to carburization, scaling, and thermal fatigue makes them essential for challenging applications.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved