Neil Metals, located in Kolkata, India, has built a solid reputation as a manufacturer and supplier of Inconel 601 Bars and Rods. They cater to industries that require exceptional oxidation resistance and high-temperature strength. With a strong focus on metallurgical expertise and a commitment to global quality standards, Neil Metals delivers Inconel 601 products that boast impressive dimensional accuracy, durability, and performance. These bars and rods are perfect for tough industrial settings, such as thermal processing, chemical plants, and power generation. Prioritizing customer satisfaction, Neil Metals guarantees timely deliveries, technical support, and tailored solutions for clients both at home and abroad.

Inconel 601 is a nickel-chromium-iron alloy made up of Nickel (58–63%), Chromium (21–25%), and Iron (the balance), along with Aluminum (1–1.7%) and trace elements. This unique blend offers remarkable oxidation resistance at high temperatures, along with excellent mechanical strength and good resistance to carburization and spalling. Typically, Inconel 601 Bars and Rods have a tensile strength ranging from 600 to 800 MPa, showcasing high creep resistance and stability even when exposed to elevated temperatures for extended periods, making them ideal for demanding structural applications.

Specification : ASTM B 166 / ASME SB 166, AMS 5715, DIN 17752, DIN 17753, DIN 17754, EN10095, ISO9723, ISO 9724, ISO 9725

Dimensions : ASTM, ASME and API

Size : 5 mm To 500 mm Dia in 100 mm TO 6000 mm Length available with NACE MR 01-75.

Diameter : 0.1 mm to 100 mm

Length : 100 mm To 3000 mm Long & Above

Finish : Bright, Polish & Black

Grade : Inconel 601 – UNS N06601

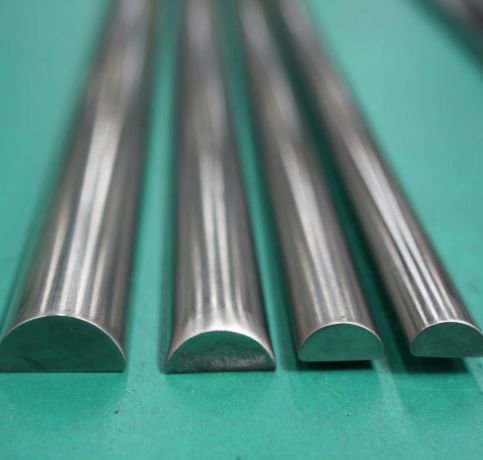

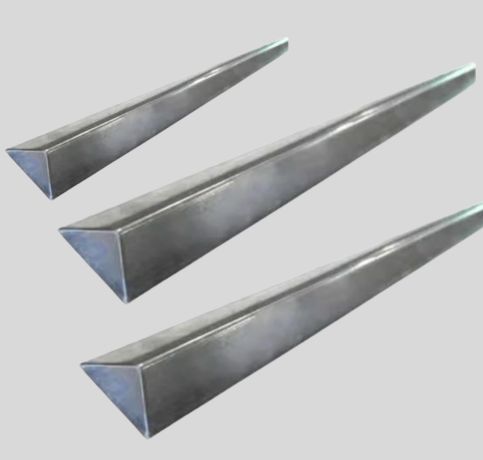

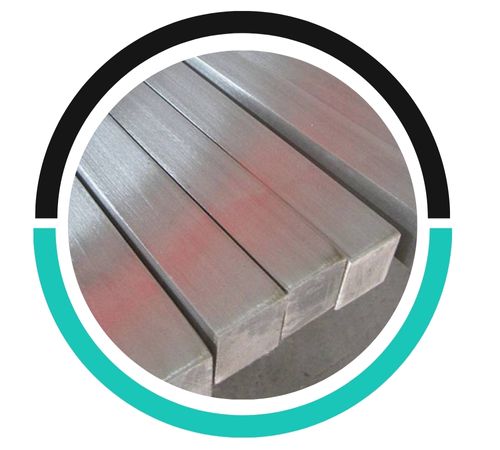

Form : Round, Square, Hex (A/F), Rectangle, Wire (Coil Form), Wire-mesh, Billet, Ingot, Forging Etc.

Our Inconel 601 Round Bars conforms to NACE MR0175/ISO 15156

| Grade | C | Mn | Si | Cu | S | Fe | Mo | Ni | Cr |

| Inconel 601 | 0.10 max | 1 max | 0.50 max | 1 max | 0.15 min | balance | – | 58 – 63 | 21 – 25 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.1 g/cm3 | 1411 °C (2571 °F) | Psi – 80,000 , MPa – 550 | Psi – 30,000 , MPa – 205 | 30 % |

| STANDARD | WERKSTOFF NR. | UNS | GOST | AFNOR | JIS | BS | EN | OR |

| Inconel 601 | 2.4851 | N06601 | XH60BT | NC23FeA | NCF 601 | NA 49 | NiCr23Fe | ЭИ868 |

Yes, we provide bars and rods in standard and customized dimensions and polishes to meet your specific project requirements. For more details mail us on sales@neilmetals.co.in

Inconel 601 bars and rods are primarily used in high-temperature and high-pressure environments, including power plants, chemical processing, and nuclear reactors, due to their excellent resistance to oxidation, corrosion, and stress corrosion cracking.

Inconel 601 bars and rods offer superior resistance to oxidation and corrosion at elevated temperatures, excellent weldability, and strength, making them ideal for harsh environments in industries like aerospace, chemical processing, and energy production.

These Inconel 601 Bars and Rods find extensive use in environments characterized by high heat and corrosive conditions. In the thermal processing sector, they are utilized in furnace components, heat treatment baskets, and radiant tubes. In power plants, you’ll find them in gas turbines, boilers, and exhaust systems. The chemical and petrochemical industries rely on them for reactors, catalyst supports, and process piping. Their ability to withstand oxidation, scaling, and thermal fatigue makes Inconel 601 a top-notch choice for applications where maintaining material integrity under extreme conditions is crucial.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved