Neil Metals, Kolkata, India, is a well-known producer and supplier of **Haynes 188 Bars and Rods**, providing high-quality cobalt-nickel-chromium-tungsten superalloy products customized for harsh high-temperature conditions. Produced with high-quality control and precision engineering, their Haynes 188 bars and rods are suitable for applications in industries such as aerospace, gas turbines, and industrial furnaces. Neil Metals follows quality standards to ensure each product, which is exported to global markets, meets international standards, providing reliable, strong, and high-performance components for critical applications.

Haynes 188 (UNS R30188) is a cobalt-nickel-chromium-tungsten alloy containing about **39% Co (balance), 22% Ni, 22% Cr, 14% W**, trace Fe, Mn, Si, C, La, and B ([haynesintl.com][1]). It has remarkable strength and oxidation resistance at up to **1095°C (2000°F)**, with room temperature tensile strength of ~946 MPa, yield ~464 MPa, and elongation ~53% ([hightempmetals.com][2]). The alloy exhibits excellent creep and sulfidation resistance at high-temperature sulfur-rich conditions ([newayprecision.com][3]). Its full weldability (TIG, MIG, electron beam), formability, and heat treatability also accommodate hot and cold working ([haynesintl.com][1]).

| Standards : | ASTM 5772, ASME S5772 |

| Dimensions : | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Wire : | Thickness starting from 0.05mm |

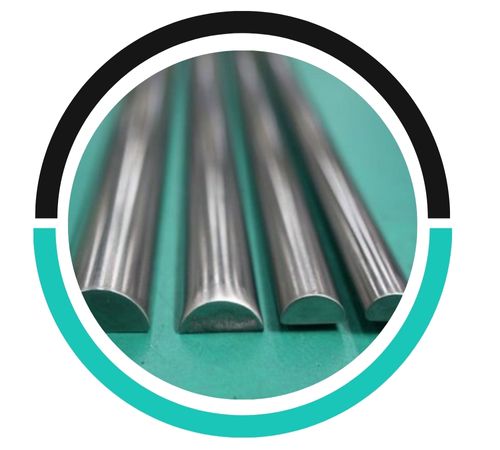

| Round bar size : | Diameter: 3-~800mm |

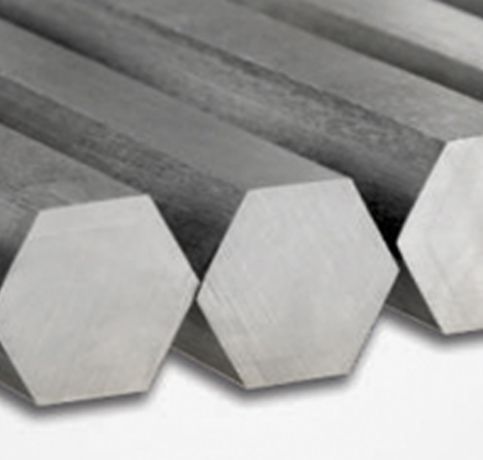

| Hex Bar size : | 2-100mm A/F |

| Flat bar size : | Thickness: 2 -100mm / Width: 10 to 500mm |

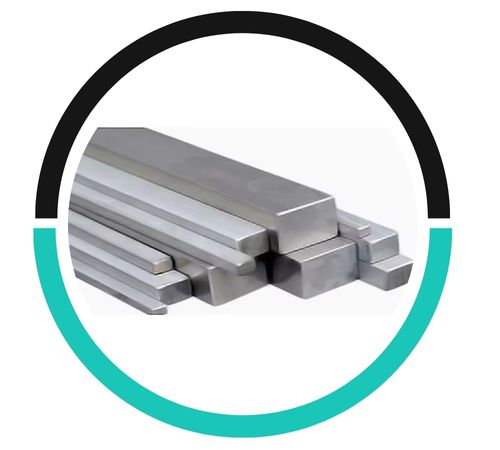

| Square bar size : | 4 to 100mm |

| Rectangular Bars Size : | 33 x 30mm to 295 x 1066mm |

| Hollow Bar : | 32mm OD x 16mm ID to 250mm OD x 200mm ID |

| Tolerance : | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Finish : | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

| Grade | C | Mn | P | S | Si | Ni | Cr | Fe | W | B | La |

| Haynes 188 | .05 – .15 | 1.25 max | .020 max | .015 max | .20 – .50 | 20.0 – 24.0 | 21.0 -23.0 | 3.0 max | 13.0 -15.0 | .015 max | .03 – .15 |

| Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| ksi – 65 , MPa – 446 | ksi – 140 , MPa – 963 | 55 % |

| STANDARD | WERKSTOFF NR. | UNS |

| Haynes 188 | 2.4683 | R30188 |

Haynes 188 Bars/Rods are widely applied in **aerospace gas turbine parts**—combustion cans, transition ducts, afterburner liners, flame holders—and **industrial turbine components**, **heat-treating and furnace components**, and **chemical/nuclear reactors** ([haynesintl.com][1]). Due to its resistance to high-temperature oxidation and sulfidation, it is best suited for **combustor atmospheres**, **industrial furnaces**, and **chemical process applications** with corrosive environments. The alloy is utilized in power generation, aerospace engines, and high-heat industrial equipment where mechanical stability and environmental resistance are essential.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved