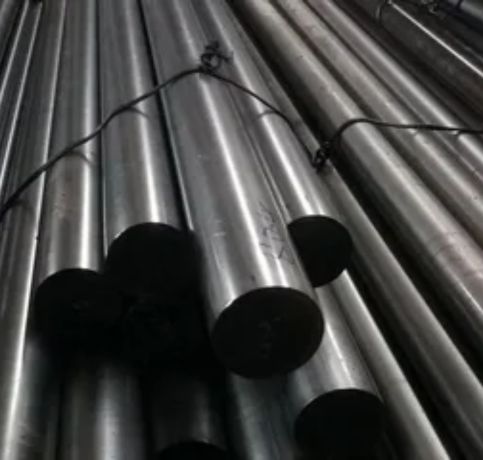

Neil Metals, located in Kolkata, India, has built a solid reputation as a reliable manufacturer and supplier of Carbon Steel Spring Bars and Rods. They’re well-known for providing durable, high-performance solutions across various industries. With a strong emphasis on quality, precision, and compliance with international standards, Neil Metals crafts spring bars and rods that can handle high stress and repeated loading with ease. These products are made using cutting-edge processes and come in a variety of sizes and finishes. Catering to sectors like automotive, construction, railways, and heavy machinery, Neil Metals guarantees dependable performance, prompt delivery, and outstanding customer support for every order.

When it comes to composition, Carbon Steel Spring Bars and Rods typically contain carbon (0.5–1.0%), manganese (0.6–1.0%), along with trace amounts of silicon, sulfur, and phosphorus. This blend gives them remarkable strength and wear resistance. Their mechanical properties boast a tensile strength ranging from 600 to 1,200 MPa, yield strength between 350 and 850 MPa, and an elongation of about 10–20%. These bars and rods are designed to resist fatigue and maintain elasticity, making them perfect for applications that require frequent bending and load-bearing without permanent deformation or failure under repeated stress.

|

Steel Grade |

C |

Mn |

Si |

P |

S |

Cr |

Ni |

B |

Cu |

Mo |

V |

|---|---|---|---|---|---|---|---|---|---|---|---|

|

55 |

0.52-0.60 |

0.50-0.80 |

0.17-0.37 |

0.035 max |

0.035 max |

0.25 max |

0.30 max |

/ |

0.25 max |

/ |

/ |

|

65 |

0.62-0.70 |

0.50-0.80 |

0.17-0.37 |

0.035 max |

0.035 max |

0.25 max |

0.25 max |

/ |

0.25 max |

/ |

/ |

|

70 |

0.62-0.75 |

0.50-0.80 |

0.17-0.37 |

0.035 max |

0.035 max |

0.25 max |

0.25 max |

/ |

0.25 max |

/ |

/ |

|

75 |

0.72-0.80 |

0.50-0.80 |

0.17-0.37 |

0.035 max |

0.035 max |

0.25 max |

0.30 max |

/ |

0.25 max |

/ |

/ |

|

85 |

0.95-1.04 |

0.40 max |

0.35 max |

0.025 max |

0.025 max |

/ |

/ |

/ |

/ |

/ |

/ |

|

65Mn |

0.62-0.70 |

0.90-1.20 |

0.17-0.37 |

0.035 max |

0.035 max |

0.25 max |

0.25 max |

/ |

0.25 max |

/ |

/ |

|

60Si2Mn |

0.56-0.64 |

0.70-1.00 |

1.50-2.00 |

0.035 max |

0.035 max |

0.35 max |

0.25 max |

/ |

0.25 max |

/ |

/ |

|

50CrVA |

0.46-0.54 |

0.50-0.80 |

0.17-0.37 |

0.025 max |

0.025 max |

0.80-1.10 |

0.35 max |

/ |

0.25 max |

/ |

0.10-0.20 |

|

55SiCrA |

0.51-0.59 |

0.50-0.80 |

1.20-1.60 |

0.025 max |

0.025 max |

0.50-0.80 |

0.35 max |

/ |

0.25 max |

/ |

/ |

|

60Si2CrA |

0.56-0.64 |

0.40-0.70 |

1.40-1.80 |

0.025 max |

0.025 max |

0.70-1.00 |

0.35 max |

/ |

0.25 max |

/ |

/ |

|

Steel Grade |

Tensile Strength Rm (Mpa) |

Yield Strength Rp0.2 (Mpa) |

Elongation A5 (%) |

Area Reduction Ratio C (%) |

|---|---|---|---|---|

|

65 |

980 min |

785 min |

9 min |

35 min |

|

70 |

1030 min |

835 min |

8 min |

30 min |

|

85 |

1130 min |

980 min |

6 min |

30 min |

|

65Mn |

980 min |

785 min |

8 min |

30 min |

|

60Si2Mn |

1275 min |

1180 min |

5 min |

25 min |

|

50CrVA |

1275 min |

1130 min |

10 min |

40 min |

|

55SiCrA |

1450-1750 |

1300 min |

6 min |

25 min |

|

60Si2CrA |

1765 min |

1570 min |

6 min |

20 min |

When selecting carbon steel spring bars, consider factors like the required strength, durability, and fatigue resistance for the specific application. Also, evaluate the environment's corrosion potential and the bar's ability to retain spring properties over time.

Carbon steel spring bars are generally not suitable for cryogenic applications due to their reduced toughness and brittleness at extremely low temperatures. Materials like stainless steel or special alloys are preferred for such conditions.

Carbon steel spring rods are available in various sizes, typically ranging from 1/4 inch to several inches in diameter, with lengths varying based on application requirements. Custom sizes can be manufactured to meet specific load, stress, or design needs.

You’ll find Carbon Steel Spring Bars and Rods in a variety of applications that call for high tensile strength, fatigue resistance, and elasticity. In the automotive sector, they’re essential for making suspension springs, stabilizer bars, and clutch springs. In construction, they play a crucial role in load-bearing assemblies, reinforcement systems, and structural components. The railway and heavy machinery industries depend on these bars and rods for shock-absorbing systems, couplings, and mechanical linkages. They’re also utilized in agricultural equipment, industrial tools, and general-purpose machinery where durability, spring action, and resistance to cyclic stress are vital for ensuring a long service life and reliability.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved