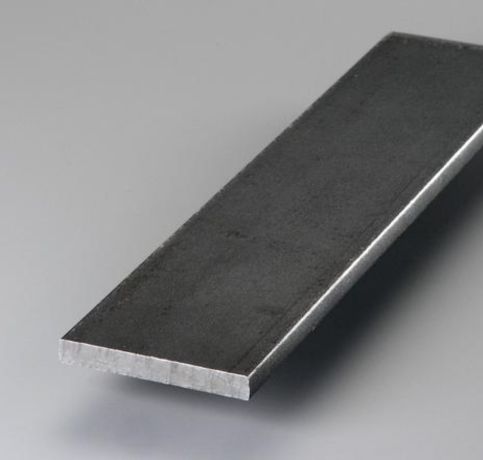

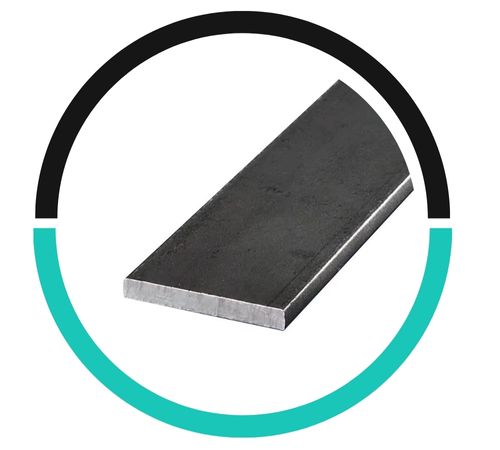

Neil Metals is a reputable manufacturer and supplier of Carbon Steel Flat Bars, proudly based in Kolkata, India. Renowned for its precision engineering and top-notch quality, Neil Metals meets a variety of industrial needs with its sturdy and dependable carbon steel products. These flat bars are produced using cutting-edge manufacturing techniques and come in a range of sizes and specifications to suit client demands. With a strong focus on quality and timely delivery, Neil Metals has built a solid reputation among clients in the construction, fabrication, automotive, and engineering sectors, both locally and internationally.

Carbon Steel Flat Bars mainly consist of carbon and iron, with different amounts of manganese, silicon, and trace elements depending on the grade. They boast impressive mechanical properties, including high tensile strength (usually between 400–550 MPa), good ductility, and moderate toughness. The yield strength typically falls between 250–400 MPa, and they offer good machinability and weldability. Their hardness and wear resistance can be improved through heat treatment, making them ideal for structural and industrial applications that require strength and durability.

| Grade | Carbon Steel |

|---|---|

| Carbon Steel Square bar size | 4 to 100mm |

| CS Hollow Bar | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| Low Carbon Steel Hex Bar size | 2-100mm A/F |

| Carbon Steel Angle bar size | 3mm*20mm*20mm~12mm*100mm*100mm |

| CS Rectangles Size | 33 x 30mm to 295 x 1066mm |

| Low Carbon Steel Flat bar size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| Carbon Steel Channel Bar | 80 x 40mm to 150 x 75mm section; 5.0 to 6.0mm thickness |

| CS Section | 3.0 to 12.0mm thickness |

| Low Carbon Steel Round bar size | Diameter: 3-~800mm |

| Carbon Steel Billet Size | 1/2″ to 495mm Diameter |

| CS Round Bar Standard Dimensions | Diameter / Height: Carbon Steel Rod and Bar Sizes : 0.5 inches / 0.625 inches / 0.75 inches / 0.875 inches / 1.0 inches / 1.125 inches / 1.25 inches / 1.375 inches / 1.5 inches / 1.75 inches / 2.0 inches / 2.25 inches / 2.5 inches / 2.75 inches / 3.0 inches / 3.25 inches / 3.5 inches / 3.75 inches / 4.0 inches / 4.25 inches / 4.5 inches / 5.0 inches / 5.25 inches / 5.5 inches / 6.0 inches / 7.0 inches / 8.0 inches / 9.0 inches. |

| Carbon Steel Surface | Bright, Hot Rolled Pickled, Cold Drawn, Sand Blasting Finished, Polished, Hairline |

| CS Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Low Carbon Steel Technique | Carbon Steel Hot Rolled, Cold Drawn, Cold Rolled, Forged Round Bar, Rod |

| Carbon Steel Condition | Hardened & tempered, annealed |

| Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Form | Carbon Steel Round, Rod, T-Bar, Channel Bar, Precision Ground Bar, Flat Bar, Square Bar, Blocks, Round Rod, Rings, Hollow, Triangle, Rectangle, Hex (A/F), Threaded, Half Round Bar, Profiles, Billet, Ingot, I/H Bar, Forging etc. |

| Processing | Bar cutting to 650mm |

| Our Carbon Steel Round bar conforms to NACE MR0175/ISO 15156 | |

| Carbon Steel Grades | C | Mn | Si | S Max. | P Max. |

|---|---|---|---|---|---|

| Ck 45 | 0.42/0.50 | 0.50/0.80 | 0.15/0.35 | 0.04 | 0.04 |

| Ck 55 | 0.52/0.60 | 0.60/0.90 | 0.15/0.35 | 0.04 | 0.04 |

| Ck 60 | 0.57/0.65 | 0.60/0.90 | 0.15/0.35 | 0.04 | 0.04 |

| SAE1006 | 0.08 max | 0.25/0.40 | 0.10/0.30 | 0.05 | 0.04 |

| SAE1008 | 0.10 max | 0.30/0.50 | 0.10/0.30 | 0.05 | 0.04 |

| SAE1010 | 0.08/0.13 | 0.30/0.60 | 0.10/0.30 | 0.05 | 0.04 |

| SAE1018 | 0.15/0.20 | 0.60/0.90 | 0.10/0.30 | 0.05 | 0.04 |

| SAE1020 | 0.18/0.23 | 0.30/0.60 | 0.10/0.30 | 0.09 | 0.04 |

| SAE1030 | 0.28/0.34 | 0.60/0.90 | 0.10/0.40 | 0.05 | 0.04 |

| SAE1035 | 0.32/0.38 | 0.60/0.90 | 0.10/0.40 | 0.05 | 0.04 |

| SAE1040 | 0.37/0.44 | 0.60/0.90 | 0.10/0.40 | 0.05 | 0.04 |

| SAE1045 | 0.40/0.50 | 0.60/0.90 | 0.10/0.40 | 0.05 | 0.04 |

| En-8D | 0.40/0.45 | 0.70/0.90 | 0.05/0.35 | 0.06 | 0.06 |

| En-9 | 0.50/0.60 | 0.50/0.80 | 0.05/0.35 | 0.06 | 0.06 |

| Grade | Yield Strength, | Tensile Strength, | Elongation at Break (in 50 mm) | Bulk Modulus (typical for steel) | Modulus of Elasticity | HBW | Poissons Ratio | Fatigue strength coefficient, of (Mpa) | Shear Modulus | Impacting Energy | Reduction of area, min: |

|---|---|---|---|---|---|---|---|---|---|---|---|

| a36 | 250 MPa | 400 – 550 MPa | 23.00% | 140 GPa | 200 GPa | 0.26 | 79.3 GPa | ||||

| 36300 psi | 58000 – 79800 psi | 23.00% | 20300 ksi | 29000 ksi | 0.26 | 11500 ksi | |||||

| EN45 | 35 (241) | 80 (551) | 40% | 204 Gpa | 948 | ≥63 | |||||

| EN19 | ≥930 Mpa | ≥1080 Mpa | ≥12 | 217 | ≥45 | ||||||

| 105 | 36,000 psi [250 MPa] | 70,000 psi (485 MPa] | 187 | 30% min | |||||||

| EN8 | ≥210 | ≥380 | ≥25 | ≤111HB | ≥50 |

Yes, common coatings for carbon steel flat bars include galvanizing, powder coating, zinc plating, epoxy coating, and polyurethane coating to enhance corrosion resistance and durability for various applications.

The different types of carbon steel flat bars include mild steel, medium carbon steel, high carbon steel, alloy steel, and tool steel, each offering various strength, hardness, and wear resistance properties.

Yes, carbon steel flat bars can be recycled. After use, they can be melted down and repurposed for new steel products, reducing waste and conserving resources in manufacturing.

These Carbon Steel Flat Bars are widely utilized across various industries due to their strength, durability, and versatility. In construction, they act as essential components for structural frameworks, supports, and reinforcements. In the automotive sector, they are used to create chassis parts, brackets, and other components. Additionally, these bars find common use in shipbuilding, railways, industrial fabrication, and agricultural equipment. Their ease of machining and welding makes them perfect for custom fabrication projects and heavy machinery. They are also employed in the production of tools, base plates, grating, and various mechanical parts that demand high strength.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved