Neil Metals, located in Kolkata, India, has made a name for itself as a top-notch manufacturer and supplier of high-quality Carbon Steel EN-9 Bars. With a strong dedication to precision and quality, Neil Metals produces EN-9 bars that adhere to strict international standards, guaranteeing durability and outstanding mechanical performance. These bars are popular across various industries thanks to their exceptional strength and wear resistance. Available in a range of sizes and finishes, Neil Metals serves sectors like automotive, construction, machinery, and manufacturing. Their commitment to timely delivery and customer satisfaction has made them a go-to choice for reliable carbon steel EN-9 bar products throughout India and beyond.

Carbon Steel EN-9 Bars are primarily made up of carbon (0.36–0.44%), manganese (0.50–0.80%), along with small amounts of sulfur and phosphorus. This blend provides good tensile strength and toughness while maintaining moderate hardness. In terms of mechanical properties, EN-9 bars usually exhibit a tensile strength of 580–700 MPa, a yield strength of around 330 MPa, and an elongation of about 15–20%. These bars are recognized for their excellent machinability, wear resistance, and moderate toughness, making them perfect for components that face medium stress and impact.

| Grade | 070M55 / EN-9 |

|---|---|

| Specification | BS 970 1991 |

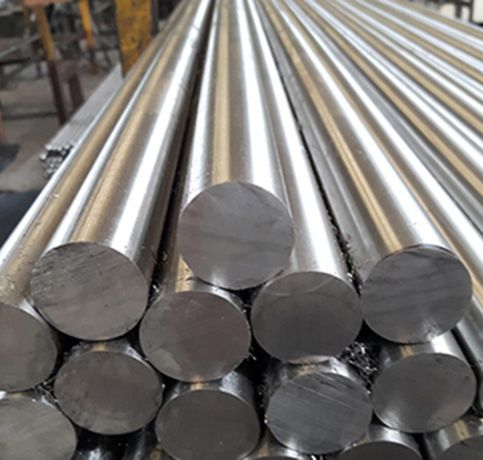

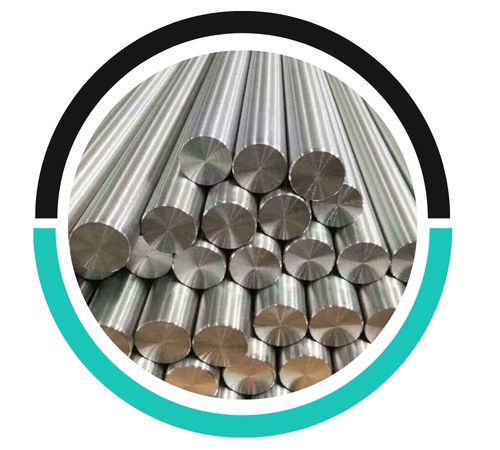

| Round Bar Size | Diameter: 3-~800mm |

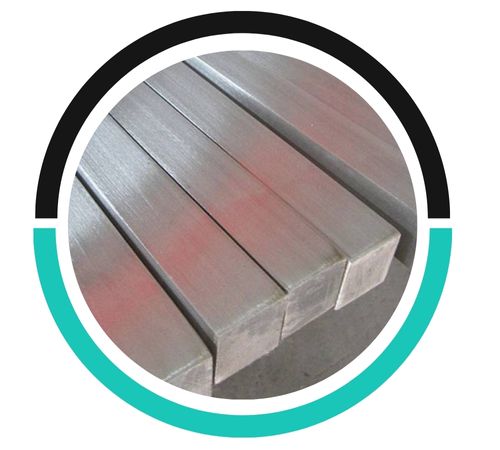

| Square Bar size | 4 to 100mm |

| Flat Bar Size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

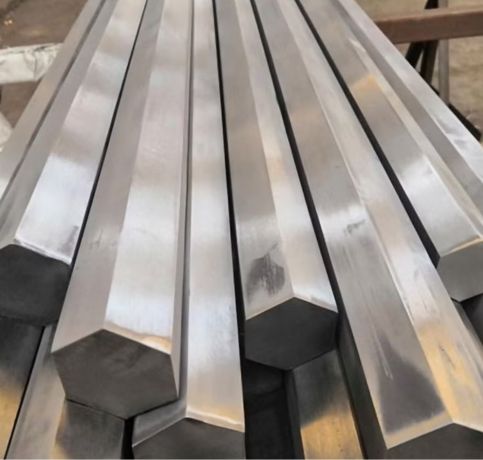

| Hex Bar Size | 2-100mm A/F |

| Rectangles Size | 33 x 30mm to 295 x 1066mm |

| Hollow Bar | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| Angle Bar Size | 3mm*20mm*20mm~12mm*100mm*100mm |

| Channel Bar | 80 x 40mm to 150 x 75mm section; 5.0 to 6.0mm thickness |

| Section | 3.0 to 12.0mm thickness |

| Billet Size | 1/2″ to 495mm Diameter |

| Finish | Cold (bright) drawn, centreless ground,smooth turned, Rough Turned, Bright, peeled, hot rolled, hot rolled annealed, slit rolled edge, Polish, Grinding, Centreless Ground & Black |

| Tolerance | K9, K10, K11, K12, H8, H9, H10, H11, H12, H13, or as per clients’ requirements |

| Surface | Polished, Bright, Cold Drawn, Hot Rolled Pickled, Sand Blasting Finished, Hairline |

| Condition | Hardened & Tempered, Annealed |

| Technique | en9 Hot Rolled, Cold Rolled, Cold Drawn, Forged Round Bar, Rods |

| Processing | Bar cutting to 650mm |

| Form | en9 Welding Rod, Round, Round Rod, Rings, Hollow, Rod, T-Bar, Channel Bar, Flat Bar, Square, Blocks, Precision Ground Bar, Triangle, Rectangle, Hex (A/F), Threaded, Ingot, I/H Bar, Half Round Bar, Profiles, Billet, Forging etc. |

| EN9 / 070M55 Bars and Rods Conforms To NACE MR0175/ISO 15156 | |

| Grade | Cr | C | Ni | Si | S | Mn | P | Mo |

| EN – 9 | – | .50 – .60 | – | .05 – .35 | .040 MAX | .50 – .80 | .040 MAX | – |

| Heat Treatment | Condition Tons/SQ.inch | Tensile Stress RE MPA | RP0.2 MPA | A min on 5.65so | Impac | Hardness HB | Limited Ruling Section mm | |

| IZODFT.L.b | KCV Joules | |||||||

| Normalise | 45 | 700 | – | 12 | – | – | 201-255 | 63 |

| 39 | 600 | – | 13 | – | – | 170/223 | 250 | |

| R | 45/55 | 700/850 | 385 | 14 | – | – | 201/277 | 100 |

| S | 50/60 | 775/925 | 450 | 14 | – | – | 223/277 | 63 |

| T | 55/65 | 850/1000 | 555 | 12 | – | – | 248/302 | 19 |

| Standard | CS EN-9 |

| UNS | – |

| WERKSTOFF NR. | CK55 |

| BS | 070M55 |

| IS | C55 |

| JIS | – |

| EN | EN9 |

| SAE/AISI | 1055 |

Carbon Steel EN-9 is commonly used for manufacturing bolts, nuts, fasteners, and structural components in heavy-duty applications like automotive and construction industries.

EN-9 offers excellent tensile strength, wear resistance, and hardenability, making it suitable for components subjected to mechanical stresses and heavy-duty environments.

Yes, Carbon Steel EN-9 can be heat-treated to enhance its hardness and strength, making it versatile for various engineering applications.

In the engineering and manufacturing sectors, Carbon Steel EN-9 Bars are widely utilized where strength and wear resistance are crucial. They are often used to create gears, shafts, studs, bolts, and other machine parts that require toughness and durability. The automotive industry relies on EN-9 bars for transmission and engine components, while construction and agricultural equipment also benefit from these bars in load-bearing parts and structural applications. Their versatility and dependable mechanical properties make EN-9 bars ideal for situations involving moderate to high stress and impact conditions.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved