Neil Metals, located in Kolkata, India, stands out as a top manufacturer and supplier of high-quality Carbon Steel EN-8 Bars. Known for their precision in manufacturing and a strong commitment to international standards, Neil Metals offers EN-8 bars that are celebrated for their impressive strength, toughness, and machinability. These bars are crafted using cutting-edge technology to guarantee consistent quality and durability. Catering to a variety of industries, including automotive, engineering, construction, and heavy machinery, Neil Metals provides tailored sizes and finishes, ensuring timely delivery. Their dedication to exceptional product performance and customer satisfaction has made them a go-to choice for reliable Carbon Steel EN-8 Bars in India.

Carbon Steel EN-8 Bars typically consist of carbon (0.35–0.45%), manganese (0.60–0.90%), along with small amounts of sulfur and phosphorus. This specific composition gives the bars good tensile strength, hardness, and moderate ductility. The mechanical properties feature a tensile strength of about 620–750 MPa, yield strength around 310 MPa, and elongation ranging from 12–16%. EN-8 bars are known for their excellent machinability and wear resistance, making them perfect for components that face moderate stress and impact while still maintaining toughness and durability.

| Grades | EN 8, EN 19, EN 24, EN 31 |

| Dimensions | EN, DIN, JIS, ASTM, BS, ASME, AISI |

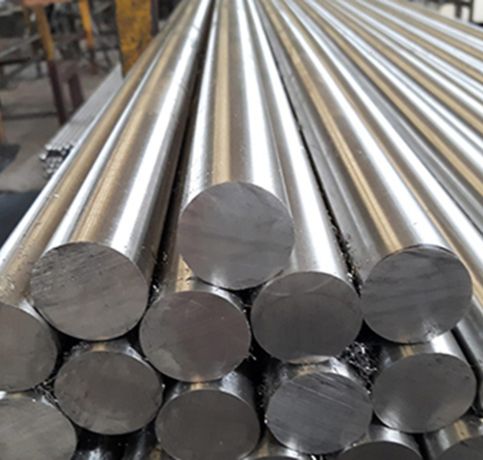

| Carbon Steel EN Series Round Bars | 3.0 – 50.8 mm, Over 50.8 – 300mm |

| Carbon Steel EN Series Rectangular Bars | 6.35 x 12.7mm,6.35 x 25.4mm,12.7 x 25.4mm |

| Carbon Steel EN Series Hex Bars | AF5.8mm–17mm |

| Carbon Steel EN Series Square Bars | AF2mm – 14mm, AF6.35mm,9.5mm,12.7mm, 15.98mm,19.0mm, 25.4mm |

| Carbon Steel EN Series Flat Bars | 1/2” to 10” in thickness range of 2mm to 150mm |

| Length | 1 to 6 Meters, Custom Cut Lengths |

| Finish | Bright, Polish & Black |

| Form | Round, Square, Hex (A/F), Rectangle, Wire (Coil Form), Wire-mesh, Billet, Ingot, Forging Etc. |

| Grade | ||||||

| C% | Si% | Mn% | Cr% | Mo% | W% | |

| EN-1A | 0.007 TO 0.15 | 0.10 | 0.80 TO 1.00 | S | P | – |

| 0.20 TO 0.30 | 0.70 MAX | |||||

| EN-8 | 0.35 TO 0.45 | 0.05 TO 0.30 | 0.60 TO 1.00 | S | P | – |

| 0.06 MAX | 0.06 MAX | |||||

| EN-9 | 0.50 TO 0.60 | 0.05 TO 0.30 | 0.5 TO 0.80 | – | – | – |

| EN-19(V 320) | 0.35 TO 0.45 | 0.10 TO 0.30 | 0.5 TO 0.80 | 0.90 TO 1.40 | 0.20 TO 0.40 | |

| EN-24(V 130) | 0.35 TO 0.45 | 0.10 TO 0.35 | 0.45 TO 0.70 | 0.90 TO 1.40 | 0.20 TO 0.35 | NI |

| 1.3 TO 1.8 | ||||||

| EN-31 R-100 | 0.90 TO 1.20 | 0.10 TO 0.35 | 0.30 TO 0.75 | 1.00 TO 1.60 | – | – |

| EN-36C E-200 | 0.12 TO 0.18 | 0.10 TO 0.35 | 0.30 TO 0.60 | 0.60 TO 1.10 | – | NI |

| 3.0 TO 3.75 | ||||||

| EN-42 | 0.70 TO 0.85 | 0.10 TO 0.40 | 0.55 TO 0.75 | – | – | – |

| EN-44 | 0.90 TO 1.20 | 0.30 | 0.45 TO 0.70 | – | – | – |

| EN-45 F-110 | 50 TO 0.60 | 1.5 TO 2.0 | 0.70 TO 1.00 | – | – | – |

| EN-351 | 0.10 TO 0.20 | 0.35 | 0.60 TO 1.00 | 0.40 to 0.80 | 0.08 to 0.10 | NI |

| 0.60 TO 1.00 | ||||||

| EN-353 | 0.10 TO 0.20 | 0.35 | 0.50 TO 1.00 | 0.75 TO 1.25 | 0.08 to o.15 | NI |

| 1.00 TO 1.50 |

| Annealed | R | S | T | U | V | W | Y | |

|---|---|---|---|---|---|---|---|---|

| Ruling Section (mm) | 150 | 150 | 100 | 65 | 65 | 30 | 30 | 25 |

| Tensile Strength (MPa) | 680/720 | 690/850 | 770/930 | 850/1000 | 930/1080 | 1000/1160 | 1080/1240 | 1280 |

| Yield Stress (MPa) | 440/480 | 480 | 570 | 665 | 740 | 835 | 895 | 1050 |

| Elongation (% Min) | 22 | 15 | 15 | 13 | 12 | 12 | 10 | 10 |

| ISO V Impact (Joule) | 30 | 30 | 30 | 30 | 25 | 25 | 22 | 7 |

| Hardness (Brinell) | 190/210 | 201/255 | 223/277 | 248/302 | 269/321 | 293/341 | 311/375 | 363/415 |

| Proof Stress (0.2%) if required (MPa, Min) | 495 | 550 | 630 | 710 | 770 | 850 | 985 |

| Standard | CS EN-19 |

| UNS | – |

| WERKSTOFF NR. | 42Cr4Mo2 |

| BS | 709M40 |

| IS | 40Cr4Mo3 |

| JIS | – |

| EN | EN19 |

| SAE/AISI | 4140,4142 |

They offer high tensile strength, wear resistance, and excellent machinability, making them suitable for demanding applications.

They are widely used in automotive, engineering, and heavy machinery industries for components like gears, shafts, and bolts.

Yes, we provide EN-8 Bars and Rods in various sizes and specifications to meet specific project requirements.

These Carbon Steel EN-8 Bars are widely utilized across various industries for creating parts that require strength, wear resistance, and toughness. They are frequently found in automotive components like shafts, gears, studs, and bolts. In the engineering and machinery sectors, EN-8 bars are ideal for producing axles, couplings, and fasteners. Additionally, construction and agricultural equipment manufacturers depend on these bars for robust structural components. With their outstanding mechanical properties and versatility, EN-8 bars are well-suited for applications that demand reliable performance under moderate to high-stress conditions.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved