Neil Metals, based in Kolkata, India, has built a solid reputation as a manufacturer and supplier of top-notch Carbon Steel EN-45 Bars. They’re well-known for their precision and commitment to international quality standards, offering EN-45 bars that boast impressive strength, hardness, and wear resistance. Utilizing cutting-edge technology, these bars are crafted to ensure consistency and durability, making them perfect for tough industrial applications. Catering to industries like automotive, heavy machinery, construction, and manufacturing, Neil Metals delivers customized solutions with prompt service and competitive pricing, making them a go-to choice for reliable, high-performance carbon steel EN-45 bars.

When it comes to composition, Carbon Steel EN-45 Bars mainly consist of carbon (0.42–0.50%), manganese (0.60–0.90%), along with small amounts of sulfur and phosphorus. This blend results in high tensile strength, hardness, and moderate ductility. On the mechanical side, EN-45 bars showcase a tensile strength of about 700–850 MPa, a yield strength around 400 MPa, and an elongation of roughly 12–15%. They also offer excellent machinability and wear resistance, making them ideal for components that need to withstand heavy-duty demands.

| Grade | EN45 |

|---|---|

| Specification | BS970 1.0904 55Si7 55S6 55Si2Mn ASTM 9255 |

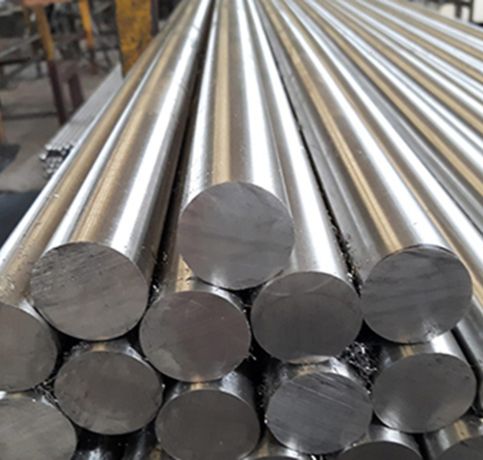

| Round bar size | Diameter: 3-~800mm |

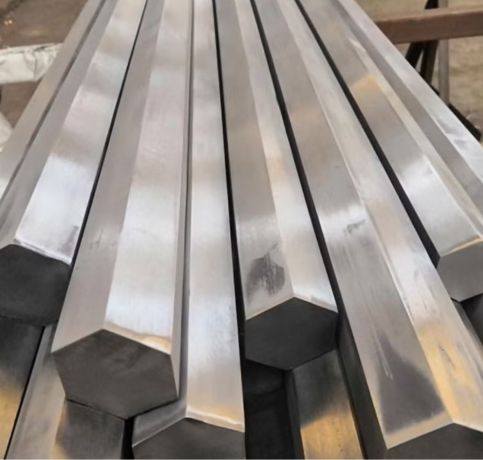

| Hex Bar size | 2-100mm A/F |

| Flat bar size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| Square bar size | 4 to 100mm |

| Angle bar size | 3mm*20mm*20mm~12mm*100mm*100mm |

| Section | 3.0 to 12.0mm thickness |

| Channel Bar | 80 x 40mm to 150 x 75mm section; 5.0 to 6.0mm thickness |

| Hollow Bar | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| Billet Size | 1/2″ to 495mm Diameter |

| Rectangles Size | 33 x 30mm to 295 x 1066mm |

| Finish | Cold (bright) drawn, centreless ground,smooth turned, peeled, slit rolled edge, hot rolled, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Surface | Bright, Hot Rolled Pickled, Cold Drawn, Sand Blasting Finished, Polished, Hairline |

| Condition | Hardened & tempered, annealed |

| Technique | EN45 Hot Rolled, Cold Drawn, Cold Rolled, Forged Round Bar, Rod |

| Processing | Bar cutting to 650mm |

| Form | EN45 Welding Rod, Round, Rod, T-Bar, Channel Bar, Precision Ground Bar, Flat Bar, Square, Blocks, Round Rod, Rings, Hollow, Triangle, Rectangle, Hex (A/F), Threaded, Half Round Bar, Profiles, Billet, Ingot, I/H Bar, Forging etc. |

| Our EN45 round bar conforms to NACE MR0175/ISO 15156 | |

| Element | En42J |

| C | 0.75 – 0.90% |

| Mn | 0.50 – 0.90% |

| Si | 0/1 – 0.35 |

| S | 0.04% Max |

| P | 0.04% Max |

|

ULTIMATE TENSILE STRENGTH, S. (MPA) |

621 |

|---|---|

|

Modulus of elasticity, E (Gpa) |

204 |

|

Fatigue strength coefficient, of (Mpa) |

948 |

|

Fatigue strength exponent, b |

-0.092 |

|

Fatigue ductility coeffient ,ef |

0.26 |

|

Fatigue ductility exponent,c |

-0.445 |

|

Type |

SIZES (mm) |

SIZES (Inches) |

ISO Tolerance |

|---|---|---|---|

|

Cold Drawn and Polish |

3.00 – 75.00 |

1/8″ – 3.00″ |

h8-h9-h10-h11 |

|

Cold Drawn and Ground |

10.00 – 75.00 |

5/6″ – 2.50″ |

h8-h9-h10-h11 |

|

Peeled and Polished |

40.00 – 150.00 |

1.50″ – 6.00″ |

h11, h11-DIN 1013 |

|

Peeled and Ground |

20.00 – 50.00 |

3/4″ – 2.00″ |

h9-h10-h11 |

EN-45 Bars and Rods are primarily used in automotive components like springs, shafts, and crankshafts, as well as in engineering tools and machinery parts requiring high strength and wear resistance.

EN-45 Bars and Rods offer excellent tensile strength (700-900 MPa), yield strength (450-600 MPa), and toughness, making them ideal for high-stress applications.

Yes, we offer customized Carbon Steel EN-45 Bars and Rods in various sizes and specifications to meet specific application needs.

In the engineering and manufacturing sectors, Carbon Steel EN-45 Bars are widely used for parts that require exceptional strength and durability. They’re perfect for crafting gears, shafts, bolts, studs, and other mechanical components that face heavy loads and wear. The automotive industry relies on EN-45 bars for transmission parts and engine components, while the construction and heavy machinery sectors use them for structural components and equipment parts. With their outstanding combination of hardness and toughness, EN-45 bars are well-suited for applications that demand resistance to wear, fatigue, and impact.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved