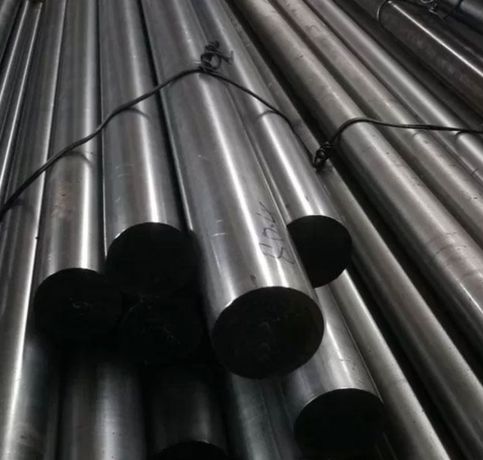

Neil Metals, a well-respected manufacturer and supplier located in Kolkata, India, is dedicated to providing top-notch Carbon Steel EN-44 Bars to a variety of industries. Renowned for their precision engineering and unwavering quality, Neil Metals guarantees that each bar adheres to international standards and meets customer expectations. Thanks to their advanced manufacturing techniques and rigorous quality control, the company has earned a strong reputation for reliability and durability in the carbon steel market. Their EN-44 bars are highly sought after for their impressive performance in demanding applications, making Neil Metals a go-to partner for industrial and engineering needs both locally and globally.

Carbon Steel EN-44 Bars are primarily made up of carbon, manganese, and trace amounts of silicon and sulfur, which give them remarkable strength and wear resistance. They boast mechanical properties like high tensile strength (usually between 700–850 MPa), good hardness, and moderate ductility. These bars are known for their toughness and can withstand significant stress without losing shape. The specific alloy composition allows for heat treatment, which further boosts their hardness and strength. Carbon Steel EN-44 Bars are perfect for creating components that need to be durable and impact-resistant, making them ideal for tough mechanical applications and challenging operating environments.

| Specifications | ASTM B446 / ASTM SB446 |

| size | 2-100mm A/F |

|---|---|

| Square bar size | 4 to 100mm |

| Flat bar size | Thickness: 2 -100mm Width: 10 to 500mm |

| Round bar size | Diameter: 3-~800mm |

| Rectangles Size | 33 x 30mm to 295 x 1066mm |

| Angle bar size | 3mm*20mm*20mm~12mm*100mm*100mm |

| Section | 3.0 to 12.0mm thickness |

| Channel Bar | 80 x 40mm to 150 x 75mm section; 5.0 to 6.0mm thickness |

| Hollow Bar | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| Billet Size | 1/2″ to 495mm Diameter |

| Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Surface | Hot Rolled Pickled, Bright, Sand Blasting Finished, Cold Drawn, Hairline, Polished |

| Condition | Hardened & tempered, annealed |

| Technique | Cold Drawn, Hot Rolled, Forged Round Bar,Cold Rolled, Rod |

| Processing | Bar cutting to 650mm |

| Form | Round, Welding Rod, T-Bar, Rod, Precision Ground Bar, Channel Bar, Square, Flat Bar, Blocks, Round Rod, Hollow, Rings, Rectangle, Hex (A/F), Triangle, Threaded, Profiles, Billet, Ingot, I/H Bar, Half Round Bar, Forging etc. |

| Grade | ||||||

| C% | Si% | Mn% | Cr% | Mo% | W% | |

| EN-1A | 0.007 TO 0.15 | 0.10 | 0.80 TO 1.00 | S | P | – |

| 0.20 TO 0.30 | 0.70 MAX | |||||

| EN-8 | 0.35 TO 0.45 | 0.05 TO 0.30 | 0.60 TO 1.00 | S | P | – |

| 0.06 MAX | 0.06 MAX | |||||

| EN-9 | 0.50 TO 0.60 | 0.05 TO 0.30 | 0.5 TO 0.80 | – | – | – |

| EN-19(V 320) | 0.35 TO 0.45 | 0.10 TO 0.30 | 0.5 TO 0.80 | 0.90 TO 1.40 | 0.20 TO 0.40 | |

| EN-24(V 130) | 0.35 TO 0.45 | 0.10 TO 0.35 | 0.45 TO 0.70 | 0.90 TO 1.40 | 0.20 TO 0.35 | NI |

| 1.3 TO 1.8 | ||||||

| EN-31 R-100 | 0.90 TO 1.20 | 0.10 TO 0.35 | 0.30 TO 0.75 | 1.00 TO 1.60 | – | – |

| EN-36C E-200 | 0.12 TO 0.18 | 0.10 TO 0.35 | 0.30 TO 0.60 | 0.60 TO 1.10 | – | NI |

| 3.0 TO 3.75 | ||||||

| EN-42 | 0.70 TO 0.85 | 0.10 TO 0.40 | 0.55 TO 0.75 | – | – | – |

| EN-44 | 0.90 TO 1.20 | 0.30 | 0.45 TO 0.70 | – | – | – |

| EN-45 F-110 | 50 TO 0.60 | 1.5 TO 2.0 | 0.70 TO 1.00 | – | – | – |

| EN-351 | 0.10 TO 0.20 | 0.35 | 0.60 TO 1.00 | 0.40 to 0.80 | 0.08 to 0.10 | NI |

| 0.60 TO 1.00 | ||||||

| EN-353 | 0.10 TO 0.20 | 0.35 | 0.50 TO 1.00 | 0.75 TO 1.25 | 0.08 to o.15 | NI |

| 1.00 TO 1.50 |

| Grade | HEAT TREATMENT | CORRESPONDING SPECIFICATION | |||||

| Hardening Temperature | Quenching Medium | Tempering Temperature | Brinell Rock well hardness | JAPAN JIS | AISI | POLDI THREAD | |

| EN-1A | – | – | – | – | – | – | – |

| EN-8 | 750-900 | OIL | 150-200 | ||||

| EN-9 | 850-900 | OIL | 200-250 | 55-60 | |||

| EN-19 (V 320) | 900-950 | OIL | 200-225 | 45-55 | SCM 4 | 4140 | |

| EN-24 (V 130) | 830-860 | OIL | 540-680 | 45-55 | SNCM 8 | 4340 | |

| EN-31 R-100 | 820-860 | OIL | 180-225 | 59-65 | |||

| EN-36C E-200 | 780-860 | OIL | 170-210 | 61-63 | SNC 22 | 3415 | |

| EN-42 | 600-700 | DIRECT HARDENING | 40-45 | ||||

| EN-44 | 650-750 | OIL | 150 | 45-50 | |||

| EN-45 | 830-860 | OIL | 470-520 | 50-55 | 9255 | ||

| EN-351 | 850-860 | OIL | 175-200 | 62-64 | |||

| EN-353 | 840-870 | OIL | 150-200 | 62-64 | |||

| Standard | CS EN-9 |

| UNS | – |

| WERKSTOFF NR. | CK55 |

| BS | 070M55 |

| IS | C55 |

| JIS | – |

| EN | EN9 |

| SAE/AISI | 1055 |

Yes, Carbon Steel EN-44 Bars can be heat-treated to improve mechanical properties such as strength and hardness. Common treatments include annealing, quenching, and tempering, depending on application requirements.

Carbon Steel EN-44 Bars are used in manufacturing automotive components, tools, and industrial equipment due to their excellent toughness, wear resistance, and high tensile strength, making them suitable for heavy-duty applications.

Carbon Steel EN-44 Bar offers high tensile strength (~700-850 MPa), excellent toughness, good wear resistance, moderate ductility, and hardness (~230-290 HB), making it suitable for heavy-duty applications.

Across various industries, Carbon Steel EN-44 Bars are in high demand due to their exceptional strength, wear resistance, and outstanding mechanical properties. They’re frequently used in manufacturing automotive parts like crankshafts, axles, and gears, where durability is essential. Additionally, these bars play a crucial role in the construction of heavy machinery, tools, and industrial equipment. In engineering and structural applications, EN-44 bars deliver dependable performance under high stress and load-bearing situations. Their ability to be heat treated also makes them perfect for customized components in critical engineering fields.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved