Neil Metals, based in Kolkata, India, has built a solid reputation as a top-notch manufacturer and supplier of high-quality Carbon Steel EN-36C Bars. Renowned for their precision in manufacturing and commitment to international standards, Neil Metals offers EN-36C bars that stand out for their remarkable toughness, hardenability, and wear resistance. These bars are perfect for components that face heavy loads and stress. Crafted with advanced techniques and rigorous quality control, Neil Metals provides customized EN-36C bars in a variety of sizes and finishes. The company caters to vital sectors like automotive, aerospace, defense, and heavy engineering, ensuring reliable performance, quick delivery, and consistent product quality with every order.

Carbon Steel EN-36C Bars mainly consist of carbon (0.12–0.18%), nickel (3.0–3.75%), chromium (0.9–1.2%), molybdenum (0.08–0.15%), along with trace amounts of manganese and silicon. This specific alloy composition grants excellent core strength and surface hardness after undergoing case hardening. In terms of mechanical properties, EN-36C bars showcase a tensile strength ranging from 900 to 1,100 MPa, a yield strength of about 650 MPa, and an elongation of 12 to 18%. These bars are known for their outstanding toughness, fatigue resistance, and wear characteristics, making them ideal for high-stress and high-impact applications, especially after proper heat treatment or carburizing processes.

| Dimensions | EN, DIN, JIS, ASTM, BS, ASME, AISI |

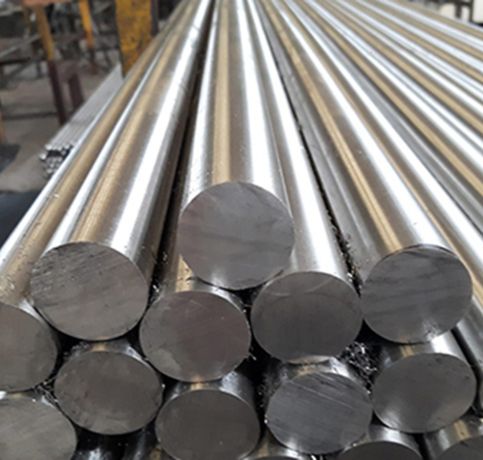

| Round Bars | 3.0 – 50.8 mm, Over 50.8 – 300mm |

| Rectangular Bars | 6.35 x 12.7mm,6.35 x 25.4mm,12.7 x 25.4mm |

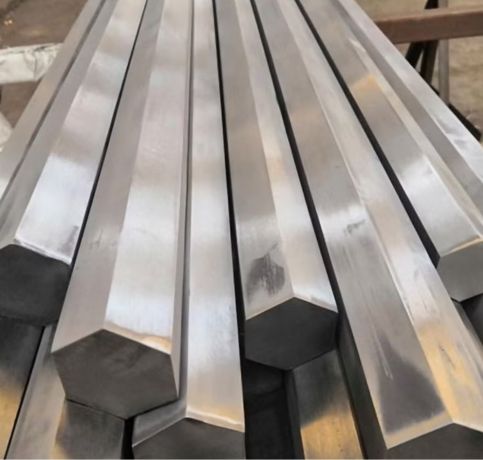

| Hex Bars | AF5.8mm–17mm |

| Square Bars | AF2mm – 14mm, AF6.35mm,9.5mm,12.7mm, 15.98mm,19.0mm, 25.4mm |

| Flat Bars | 1/2” to 10” in thickness range of 2mm to 150mm, |

| Finish | Bright, Polish & Black |

| Length | 1 to 6 Meters, Custom Cut Lengths |

| Form | Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc. |

| C | Mn | Si | P | S | Cr | Ni | Mo |

| 0.11-0.17 | 0.30-0.60 | 0.40 max | 0.025 max | 0.025 max | 0.80-1.10 | 3.00-3.50 | 0.20-0.30 |

| Process | Tensile Strength Rm (Mpa) | Elongation A5 (%) | Impact Value Kv (J) Room Temperature | Hardness (HB) |

| SOFT ANNEALED | – | – | – | 217 max |

| QUENCHED AND TEMPERED | 1230-1480 | 9 min | 35 min | 368-424 |

| DIN | EN | ANFOR | BS |

| 1.6657 | 14NiCrMo13-4 | 16NCD13 | 832M13 / EN36C |

Carbon Steel EN-36C Bars and Rods offer high strength, durability, and excellent wear resistance, making them ideal for heavy-duty applications.

These bars are commonly used in automotive, manufacturing, and construction industries for producing components that undergo high mechanical stress.

EN-36C Bars and Rods are used in the production of bearings, bushings, and structural components that require excellent toughness and fatigue resistance.

Carbon Steel EN-36C Bars find extensive use in industries where high strength, wear resistance, and toughness are crucial. In the automotive industry, they are utilized for crankshafts, gears, camshafts, and transmission components that demand hard surfaces and resilient cores. In aerospace and defense, EN-36C bars are perfect for shafts, pins, and load-bearing parts that endure dynamic stresses. In heavy machinery and industrial equipment, they are employed in components like drive shafts, gear blanks, and spindles. Their exceptional hardenability and machinability also make them ideal for die manufacturing, tool parts, and components that face surface wear and impact.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved