Neil Metals, located in Kolkata, India, has earned a solid reputation as a reliable manufacturer and supplier of top-notch Carbon Steel EN-19 (V 320) Bars. These bars are celebrated for their remarkable strength, toughness, and resistance to wear. Crafted with precision and adhering to international standards, EN-19 bars from Neil Metals are perfect for demanding engineering tasks. The company prides itself on delivering consistent quality, accurate dimensions, and timely shipments, catering to sectors like automotive, oil and gas, power generation, and general engineering. Neil Metals is dedicated to providing dependable, high-performance EN-19 bars that fulfill the rigorous requirements of today’s industrial and mechanical applications.

The Carbon Steel EN-19 (V 320) Bars are primarily made up of carbon (0.36–0.44%), chromium (0.90–1.50%), and molybdenum (0.20–0.40%), with manganese and silicon present in smaller amounts. This unique alloy composition grants them outstanding tensile strength, hardenability, and fatigue resistance. Their mechanical properties boast a tensile strength ranging from 850 to 1000 MPa, a yield strength of about 680 MPa, and an elongation of approximately 13 to 16%. EN-19 bars are known for their good toughness, wear resistance, and machinability, making them ideal for parts that face high stress and impact.

| Grades | EN 8, EN 19, EN 24, EN 31 |

| Dimensions | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Carbon Steel EN Series Round Bars | 3.0 – 50.8 mm, Over 50.8 – 300mm |

| Carbon Steel EN Series Rectangular Bars | 6.35 x 12.7mm,6.35 x 25.4mm,12.7 x 25.4mm |

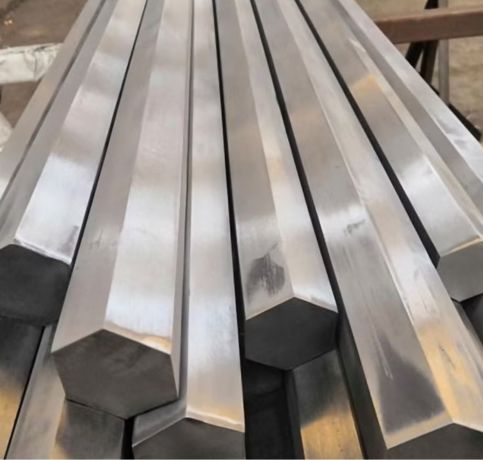

| Carbon Steel EN Series Hex Bars | AF5.8mm–17mm |

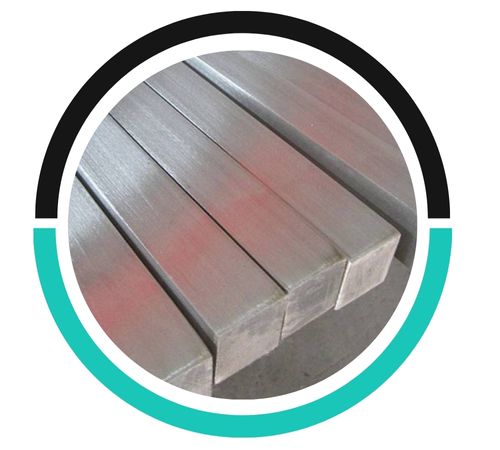

| Carbon Steel EN Series Square Bars | AF2mm – 14mm, AF6.35mm,9.5mm,12.7mm, 15.98mm,19.0mm, 25.4mm |

| Carbon Steel EN Series Flat Bars | 1/2” to 10” in thickness range of 2mm to 150mm |

| Length | 1 to 6 Meters, Custom Cut Lengths |

| Finish | Bright, Polish & Black |

| Form | Round, Square, Hex (A/F), Rectangle, Wire (Coil Form), Wire-mesh, Billet, Ingot, Forging Etc. |

| Grade | ||||||

| C% | Si% | Mn% | Cr% | Mo% | W% | |

| EN-1A | 0.007 TO 0.15 | 0.10 | 0.80 TO 1.00 | S | P | – |

| 0.20 TO 0.30 | 0.70 MAX | |||||

| EN-8 | 0.35 TO 0.45 | 0.05 TO 0.30 | 0.60 TO 1.00 | S | P | – |

| 0.06 MAX | 0.06 MAX | |||||

| EN-9 | 0.50 TO 0.60 | 0.05 TO 0.30 | 0.5 TO 0.80 | – | – | – |

| EN-19(V 320) | 0.35 TO 0.45 | 0.10 TO 0.30 | 0.5 TO 0.80 | 0.90 TO 1.40 | 0.20 TO 0.40 | |

| EN-24(V 130) | 0.35 TO 0.45 | 0.10 TO 0.35 | 0.45 TO 0.70 | 0.90 TO 1.40 | 0.20 TO 0.35 | NI |

| 1.3 TO 1.8 | ||||||

| EN-31 R-100 | 0.90 TO 1.20 | 0.10 TO 0.35 | 0.30 TO 0.75 | 1.00 TO 1.60 | – | – |

| EN-36C E-200 | 0.12 TO 0.18 | 0.10 TO 0.35 | 0.30 TO 0.60 | 0.60 TO 1.10 | – | NI |

| 3.0 TO 3.75 | ||||||

| EN-42 | 0.70 TO 0.85 | 0.10 TO 0.40 | 0.55 TO 0.75 | – | – | – |

| EN-44 | 0.90 TO 1.20 | 0.30 | 0.45 TO 0.70 | – | – | – |

| EN-45 F-110 | 50 TO 0.60 | 1.5 TO 2.0 | 0.70 TO 1.00 | – | – | – |

| EN-351 | 0.10 TO 0.20 | 0.35 | 0.60 TO 1.00 | 0.40 to 0.80 | 0.08 to 0.10 | NI |

| 0.60 TO 1.00 | ||||||

| EN-353 | 0.10 TO 0.20 | 0.35 | 0.50 TO 1.00 | 0.75 TO 1.25 | 0.08 to o.15 | NI |

| 1.00 TO 1.50 |

| Annealed | R | S | T | U | V | W | Y | |

|---|---|---|---|---|---|---|---|---|

| Ruling Section (mm) | 150 | 150 | 100 | 65 | 65 | 30 | 30 | 25 |

| Tensile Strength (MPa) | 680/720 | 690/850 | 770/930 | 850/1000 | 930/1080 | 1000/1160 | 1080/1240 | 1280 |

| Yield Stress (MPa) | 440/480 | 480 | 570 | 665 | 740 | 835 | 895 | 1050 |

| Elongation (% Min) | 22 | 15 | 15 | 13 | 12 | 12 | 10 | 10 |

| ISO V Impact (Joule) | 30 | 30 | 30 | 30 | 25 | 25 | 22 | 7 |

| Hardness (Brinell) | 190/210 | 201/255 | 223/277 | 248/302 | 269/321 | 293/341 | 311/375 | 363/415 |

| Proof Stress (0.2%) if required (MPa, Min) | 495 | 550 | 630 | 710 | 770 | 850 | 985 |

| Standard | CS EN-19 |

| UNS | – |

| WERKSTOFF NR. | 42Cr4Mo2 |

| BS | 709M40 |

| IS | 40Cr4Mo3 |

| JIS | – |

| EN | EN19 |

| SAE/AISI | 4140,4142 |

They offer high tensile strength, toughness, and excellent wear resistance, making them ideal for demanding applications.

Commonly used in automotive, aerospace, and engineering sectors for parts like crankshafts, gears, and heavy-duty machinery components.

Yes, we offer customization in sizes, lengths, and finishes to meet specific project requirements.

In various industries that require components capable of withstanding high torque, stress, and wear, Carbon Steel EN-19 (V 320) Bars are widely utilized. In the automotive field, they’re essential for producing crankshafts, gears, axles, and drive shafts. The oil and gas sector relies on them for drill collars, tool joints, and connectors. In power generation, they find their place in turbine shafts and mechanical couplings. These bars are also perfect for high-strength machine parts in construction, mining, and general engineering. Their exceptional mechanical properties make them a go-to choice for applications where strength, fatigue resistance, and durability are paramount.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved