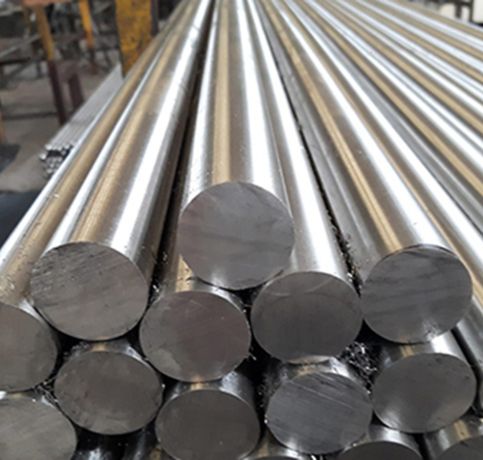

Neil Metals, located in Kolkata, India, has built a solid reputation as a manufacturer and supplier of top-notch Carbon Steel Bars and Rods. With a strong focus on excellence and precision, this company ensures that its products not only meet global standards but also address a diverse array of industrial needs. Thanks to years of experience and cutting-edge manufacturing techniques, Neil Metals delivers carbon steel solutions that are both durable and reliable, perfect for structural, automotive, and engineering applications. Their unwavering commitment to quality, prompt delivery, and competitive pricing has made them a trusted name in the carbon steel manufacturing sector, both in India and on the international stage.

When it comes to Carbon Steel Bars and Rods, they primarily consist of iron and carbon, with the carbon content typically falling between 0.05% and 2.1% by weight. To boost performance, additional elements like manganese, silicon, and copper might be included. These bars are known for their impressive tensile strength, yield strength, and hardness. Depending on the carbon content, they can be classified as low, medium, or high carbon steel. Their excellent machinability, weldability, and wear resistance make them ideal for a variety of load-bearing and high-stress applications in both industrial and commercial sectors.

| Carbon Steel Bar Standard | ASTM A36, AMS 5513, AMS 5511, AMS 5647 |

|---|---|

| Carbon Steel Bar Dimensions | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Carbon Steel Round bar size | Diameter: 3-~800mm |

| Carbon Steel Hex Bar size | 2-100mm A/F |

| CS Flat bar size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| Carbon Steel Square bar size | 4 to 100mm |

| Carbon Angle bar size | 3mm*20mm*20mm~12mm*100mm*100mm |

| Carbon Rectangular Bars Section | 3.0 to 12.0mm thickness |

| Carbon Steel Channel Bar | 80 x 40mm to 150 x 75mm section; 5.0 to 6.0mm thickness |

| ASTM A36 Type Hollow Bar | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| CS Threaded Bar Billet Size | 1/2 to 495mm Diameter |

| Carbon Steel Rectangular Size | 33 x 30mm to 295 x 1066mm |

| Carbon Hex Bars Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| ASTM A36 Type Hollow Bar Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Carbon T-Bar Surface | Bright, Hot Rolled Pickled, Cold Drawn, Sand Blasting Finished, Polished, Hairline |

| Rolled Carbon Steel Flat Bars Condition | Hardened & tempered, annealed |

| ASTM A36 Type Cold Rolled Bar Technique | Carbon Hot Rolled, Cold Drawn, Cold Rolled, Forged Round Bar, Rod |

| CS Rod Processing | Bar cutting to 650mm |

| Carbon Rounds Bar Form | Round, Rod, T-Bar, Channel Bar, Precision Ground Bar, Flat Bar, Square, Blocks, Round Rod, Rings, Hollow, Triangle, Rectangle, Hex (A/F), Threaded, Half Round Bar, Profiles, Billet, Ingot, I/H Bar, Forging etc. |

| Our Carbon Steel Round bar conforms to NACE MR0175/ISO 15156 | |

| Grades | Silicon | Mangenese | Carbon | Phosphorus. | Sulfur. |

|---|---|---|---|---|---|

| En-8D | 0.05/0.35 | 0.70/0.90 | 0.40/0.45 | 0.06 | 0.06 |

| En-9 | 0.50/0.80 | 0.50/0.60 | |||

| SAE 1006 | 0.10/0.30 | 0.25/0.40 | 0.08 max | 0.04 | 0.05 |

| SAE 1008 | 0.30/0.50 | 0.10 max | |||

| SAE 1030 | 0.10/0.40 | 0.60/0.90 | 0.28/0.34 | ||

| SAE 1035 | 0.32/0.38 | ||||

| SAE 1040 | 0.37/0.44 | ||||

| SAE 1010 | 0.10/0.30 | 0.30/0.60 | 0.08/0.13 | ||

| SAE 1018 | 0.60/0.90 | 0.15/0.20 | |||

| SAE 1020 | 0.30/0.60 | 0.18/0.23 | 0.09 | ||

| SAE 1045 | 0.10/0.40 | 0.60/0.90 | 0.40/0.50 | 0.05 | |

| Ck 45 | 0.15/0.35 | 0.50/0.80 | 0.42/0.50 | 0.04 | |

| Ck 55 | 0.60/0.90 | 0.52/0.60 | |||

| Ck 60 | 0.57/0.65 |

| Tensile Strength | Yield Stress, Min, MPa | % Elongation at gauge length 5.65 √Ѕo | Bend Test | ||

| Min, Mpa | |||||

| mm | <20 | 20-40 mm | >40 | min | min |

| mm | mm | ||||

| 410 | 250 | 240 | 230 | 23 | 3t* (*t is 3 times thickness) |

| EN | Normalized | ASTM | AMS | UNS |

|---|---|---|---|---|

| EN 1.0460 | A105n/SA 105n | ASTM A105 | ASME SA 105 | K03504 |

Carbon Steel Bars and Rods are used in industries such as construction, automotive, machinery, and manufacturing for components like shafts, bolts, and structural parts.

Yes, Carbon Steel Bars and Rods can be heat treated to enhance their hardness, strength, and wear resistance, making them suitable for demanding applications.

Carbon Steel Bars and Rods offer excellent strength, durability, and cost-effectiveness, making them ideal for a wide range of industrial applications.

Carbon Steel Bars and Rods are popular across numerous industries due to their strength, versatility, and cost-effectiveness. In construction, they’re used for reinforcement, frames, and support structures. In the automotive sector, they’re crucial for making shafts, axles, and structural components. These rods also play an essential role in industrial machinery, agricultural equipment, and railways. Their ability to adapt to heat treatment processes allows for customization in hardness and strength, making them suitable for both heavy-duty and precision engineering applications where durability and reliability are paramount.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved