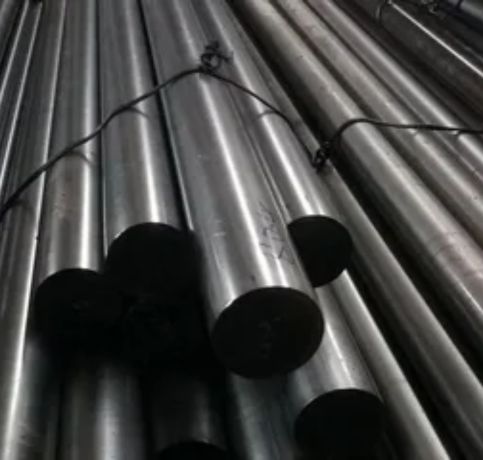

Neil Metals, based in Kolkata, India, stands out as a trusted manufacturer and supplier of high-quality C45 Round Bars, catering to a diverse array of industrial sectors with expertly crafted steel solutions. Renowned for their commitment to quality, reliability, and prompt delivery, Neil Metals ensures that their C45 Round Bars comply with both national and international standards. These bars are highly valued for their excellent machinability, toughness, and strength. With a strong emphasis on customer satisfaction, Neil Metals meets the specific needs of the automotive, machinery, construction, and engineering industries by providing customizable dimensions and specifications tailored to various application requirements.

C45 Round Bar is a medium carbon steel alloy primarily made up of carbon (0.42–0.50%), manganese (0.50–0.80%), and iron, along with trace amounts of sulfur and phosphorus. It boasts impressive tensile strength ranging from 570–700 MPa and yield strength between 330–400 MPa. This material also offers moderate wear resistance and outstanding machinability when either annealed or normalized. Thanks to its well-balanced composition and mechanical properties, C45 Round Bar is perfect for components that need moderate strength, toughness, and the capability to be heat-treated for improved performance in demanding mechanical applications.

|

Variant |

Cast |

Weldability |

C % |

Si % |

Mn % |

P % |

S % |

Cr % |

Ni % |

Mo % |

V % |

Ti % |

Cu % |

Al % |

DI % |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

SB8673 |

CC |

CEV 0.71max |

Min |

0.46 |

0.15 |

0.70 |

– |

0.020 |

0.25 |

0.10 |

– |

– |

– |

– |

0.020 |

1.70 |

|

Pcm 0.55max |

Max |

0.49 |

0.35 |

0.80 |

0.020 |

0.035 |

0.30 |

0.20 |

– |

– |

– |

0.25 |

0.040 |

2.00 |

||

|

SB1672 |

CC |

CEV 0.72max |

Min |

0.42 |

0.10 |

0.50 |

– |

0.020 |

– |

– |

– |

– |

– |

– |

– |

1.10 |

|

Pcm 0.55max |

Max |

0.50 |

0.40 |

0.90 |

0.045 |

0.045 |

0.40 |

0.40 |

0.10 |

– |

– |

– |

– |

1.80 |

||

|

SB1671 |

CC |

CEV 0.58max |

Min |

0.42 |

0.15 |

0.50 |

– |

0.035 |

– |

– |

– |

– |

– |

– |

– |

1.20 |

|

Pcm 0.51max |

Max |

0.50 |

0.40 |

0.80 |

0.045 |

0.050 |

– |

– |

– |

– |

– |

– |

– |

1.60 |

||

|

5081, Imatra 4 M |

CC |

CEV 0.72max |

Min |

0.42 |

0.10 |

0.50 |

– |

0.020 |

– |

– |

– |

– |

– |

– |

– |

1.10 |

|

Pcm 0.55max |

Max |

0.50 |

0.40 |

0.90 |

0.030 |

0.035 |

0.40 |

0.40 |

0.10 |

– |

– |

– |

– |

1.80 |

||

|

5155 |

CC |

CEV 0.72max |

Min |

0.44 |

0.10 |

0.50 |

– |

– |

– |

– |

– |

– |

– |

– |

– |

1.10 |

|

Pcm 0.55max |

Max |

0.49 |

0.40 |

0.80 |

0.030 |

0.025 |

0.40 |

0.40 |

0.10 |

– |

– |

– |

– |

1.80 |

||

|

047A |

IC |

CEV 0.76max |

Min |

0.46 |

0.15 |

0.50 |

– |

0.020 |

– |

– |

– |

– |

– |

– |

0.015 |

– |

|

Pcm 0.6max |

Max |

0.50 |

0.40 |

0.80 |

0.030 |

0.030 |

0.25 |

0.25 |

0.10 |

0.100 |

0.005 |

0.25 |

0.030 |

– |

||

|

C45 EN 10083-2:2006 |

Std |

CEV 0.68max |

Min |

0.42 |

– |

0.50 |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

|

Pcm 0.55max |

Max |

0.50 |

0.40 |

0.80 |

0.045 |

0.045 |

0.40 |

0.40 |

– |

– |

– |

– |

– |

– |

||

|

C45R EN10083-2:2006 |

Std |

CEV 0.65max |

Min |

0.42 |

– |

0.50 |

– |

0.020 |

– |

– |

– |

– |

– |

– |

– |

– |

|

Pcm 0.53max |

Max |

0.50 |

0.40 |

0.80 |

0.030 |

0.040 |

0.40 |

0.40 |

– |

– |

– |

– |

– |

– |

||

|

C45E EN 10083-2:2006 |

Std |

CEV 0.71max |

Min |

0.42 |

– |

0.50 |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

|

Pcm 0.55max |

Max |

0.50 |

0.40 |

0.80 |

0.030 |

0.035 |

0.40 |

0.10 |

– |

– |

– |

– |

– |

– |

|

Diameter d (mm) |

Thickness t (mm) |

0.2 % proof stress (N/mm2) |

Tensile strength (N/mm2) |

Elongation A5 (%) |

Reduction Z (%) |

|

<16 |

<8 |

min. 490 |

700-850 |

min. 14 |

min. 35 |

|

<17-40 |

<8<=20 |

min. 430 |

650-800 |

min. 16 |

min. 40 |

|

<41-100 |

<20<=60 |

min. 370 |

630-780 |

min. 17 |

min. 45 |

USA | Germany | China | Japan | France | England | Italy | Poland | ISO | Austria | Sweden | Spain |

ASTM/AISI/ UNS/SAE | DIN,WN-r | GB | JIS | AFNOR | BS | UNI | PN | ISO | ONORM | SS | UNE |

1045 G10450 | C45/Ck45/1.1191/C45 | 45# | S45C | C45E Ck45 | C40E 080M466 | 1660 |

Yes, C45 Round Bar can be recycled and repurposed without losing its essential properties.

C45 Round Bar does not have a specific pressure rating, as it is primarily used for mechanical and structural applications, not pressure-bearing components.

Yes, C45 Round Bar may require corrosion protection coatings when exposed to harsh environmental conditions to prevent rust and degradation.

C45 Round Bar finds extensive use across various industries due to its strength, machinability, and versatility. In the automotive field, it’s commonly used to manufacture axles, shafts, gears, crankshafts, and connecting rods. The machinery and engineering sectors utilize it for tools, spindles, and heavy-duty components that require enhanced wear resistance and durability. It’s also a great fit for construction applications, such as support bars and mechanical fasteners. Thanks to its adaptability to heat treatment processes, C45 Round Bar is a go-to material for forging and fabrication where precision and strength are essential.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved