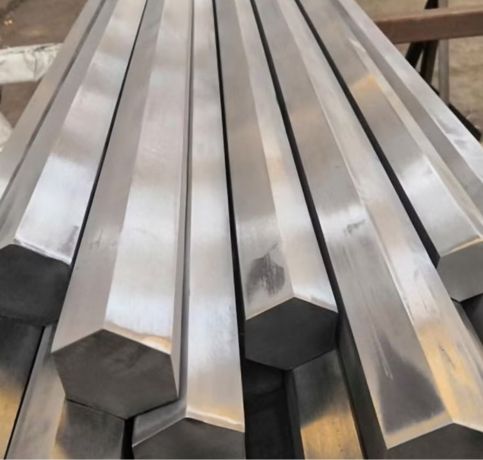

Neil Metals, located in Kolkata, India, has built a solid reputation as a manufacturer and supplier of top-notch Aluminium Hex Bars and Rods. Renowned for their precision engineering, consistent quality, and prompt delivery, the company caters to a wide range of industries. With cutting-edge facilities and a strong commitment to excellence, Neil Metals guarantees that every aluminium product adheres to both national and international standards. Their Aluminium Hex Bars and Rods are highly regarded for their strength, lightweight design, and resistance to corrosion, making them perfect for structural and industrial uses in both local and global markets.

These Aluminium Hex Bars and Rods are typically made from high-grade aluminium alloys like 6061, 6082, or 7075, which are celebrated for their impressive strength-to-weight ratio and corrosion resistance. They boast good machinability, weldability, and thermal conductivity. In terms of mechanical properties, they offer a tensile strength ranging from 150 to 550 MPa and a yield strength between 95 and 500 MPa, depending on the specific alloy and temper. With a melting point of about 660°C and elongation rates from 8% to 20%, these bars hold their shape under mechanical stress, ensuring durability and reliable performance across various conditions.

Standards : ASTM B221, B211, B565, B316, AMS 4121 2014

Temper : O

Standard : ASTM, ASME, AMS, GB/T, JIS

Length : 1000-6000

Size : 5 mm To 500 mm

Diameter : 6-150

Finish : Bright, Polish & Black

Type : Hot-Rolled (HR) / Cold-Rolled (CR) Sheet

| Alloy | Fe | Si | Mg | Mn | Cu | Zn | Ti | Cr | Others | AI |

| 1100 (min) | 0.35 | 0.25 | 0.01 | 0.01 | 0.05 | 0.01 | 0.020 | Trace | 0.05 (each) | 99.60% |

| 1100 (max) | 0.50 | 0.35 | 0.03 | 0.05 | 0.20 | 0.05 | 0.030 | Trace | 0.15 (total) | remainder |

| 5083 | 0.40 max | 0.40 max | 4.0 / 4.90 | 0.40 / 1.0 | 0.10 max | 0.25 max | 0.15 max | 0.05 / 0.25 | 0.05 max | Bal |

| 6061 | 0.7 | 0.4-0.8 | 0.8-1.2 | 0.15 | 0.15-0.4 | 0.25 | 0.15 | 0.15-0.35 | 0.005/0.15 | Remainder |

| 6068 | 0.50 max | 0.7 – 1.3 | 0.06-1.20 | 0.40-1.00 | 0.10 max | 0.20 max | 0.10 max | 0.25 max | 0.05 max | Bal |

| 7075 min | 2.10 | 1.20 | 5.10 | 0.18 | ||||||

| 7075 max | 0.50 | 0.40 | 2.90 | 0.30 | 2.00 | 6.10 | 0.20 | 0.28 | 0.05 |

| Alloy | Temper | UTS(Mpa) | % Elongation | Tensile Strength | Hardness Brinell | Proof Stress | Yield Strength (PSI) | Shear Strength (PSI) | Brinell Hardness | |||

| Min | Max | 0.5 mm -0.8 mm | 0.81 mm – 1.30 mm | 1.30 mm – above | ||||||||

| 1100 | O | 75 | 110 | 20 | 25 | 29 | ||||||

| H12 | 95 | 130 | 5 | 6 | 7 | |||||||

| H14 | 110 | 145 | 3 | 4 | 5 | |||||||

| H16 | 130 | 165 | 2 | 3 | 4 | |||||||

| H18 | 150 | — | 2 | 2 | 3 | |||||||

| 5083 | 12 Min % | 275 – 350 MPa | 75 HB | 125 Min MPa | ||||||||

| 6061 | – | 45,000 | 12 | 40,000 | 31,000 | 95 | ||||||

| 6082 | 8 | 295 | 95 | – | 240 | – | – | |||||

| 7075 T6, T651 | 11 | 83-572 | 73- 503 | 150 | ||||||||

| 7075 T73, T7351 | 13 | 73-503 | 63-434 | NA | ||||||||

| Grade | UNS | USA | Japan | France | ISO | WNR | EN | DIN | ISO | BS (OLD) |

| 1100 | A91100 | AA1100 | JIS A1100P | NF 1100 | Al 99.0 Cu. | – | – | – | – | – |

| 6082 | A96082 | AA6082 | – | – | – | 3.2315 | AW-6082 | AlMgSi1 | AlSi1MgMn | HE30 |

| 5083 | A95083 | 5083 | – | – | AlMg4,5Mn0,7 | 3.3547 | AW-AlMg4,5Mn0,7 | AlMg4,5Mn | – | – |

| 6061 | A96061 | AA6061 | – | – | – | 3.3211 | AW-AlMg1SiCu EN AW-6061 | AlMgSiCu | AlMg1SiCu | HE20 |

| 7075 | A97075 | 7075 | 3.4365 | ENAW-AlZn5.5MgCu EN AW-7075 | AlZnMgCu1.5 | AlZn6MgCu | 7075 L95 L96, V95 |

| HEXAGONS | ||

| Size(mm) | WT PER FEET IN KGS | WT PER MTR IN KGS |

| 16 | 0.55 | 1.79 |

| 18 | 0.69 | 2.27 |

| 20 | 0.85 | 2.80 |

| 22 | 1.03 | 3.39 |

| 25 | 1.33 | 4.38 |

| 28 | 1.67 | 5.49 |

| 30 | 1.92 | 6.30 |

| 32 | 2.19 | 7.17 |

| 36 | 2.77 | 9.07 |

| 38 | 3.08 | 10.11 |

| 40 | 3.41 | 11.20 |

| 45 | 4.32 | 14.18 |

| 50 | 5.34 | 17.50 |

| 56 | – | – |

| 60 | – | – |

| 65 | – | – |

| 70 | – | – |

| 75 | – | – |

| 80 | – | – |

| 90 | – | – |

| 100 | – | – |

Aluminium hex bar/rod is commonly used in aerospace, automotive, marine, construction, and manufacturing industries for lightweight structures, electrical components, fasteners, and precision machining due to its strength and corrosion resistance.

Aluminum hex bars are produced through extrusion, casting, or forging, followed by heat treatment and machining. This process enhances strength, dimensional accuracy, and surface finish, ensuring consistent quality and performance.

Yes, aluminum hex bar/rod can be welded. Recommended techniques include Tungsten Inert Gas (TIG) welding for precision, and Metal Inert Gas (MIG) welding for faster, more robust welds.

Aluminium Hex Bars and Rods find extensive applications in numerous industries thanks to their durability, corrosion resistance, and ease of machining. In the automotive field, they are used to manufacture engine components, transmission parts, and structural supports. The aerospace sector relies on them for aircraft fittings, frames, and connectors due to their lightweight and robust nature. You can also find them in marine hardware, construction projects, electrical conductors, and precision tools. Moreover, these rods are popular in architectural and decorative applications where both aesthetics and functionality are essential, showcasing their versatility across a multitude of engineering and design fields.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved