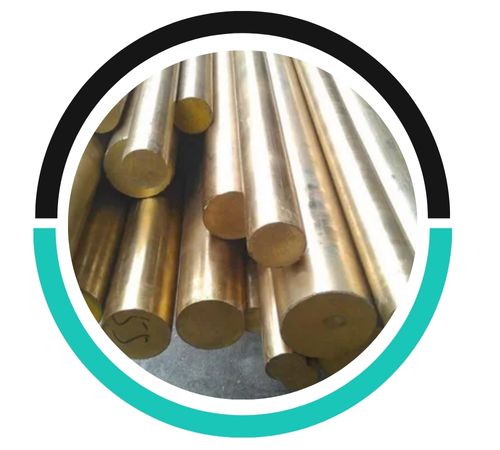

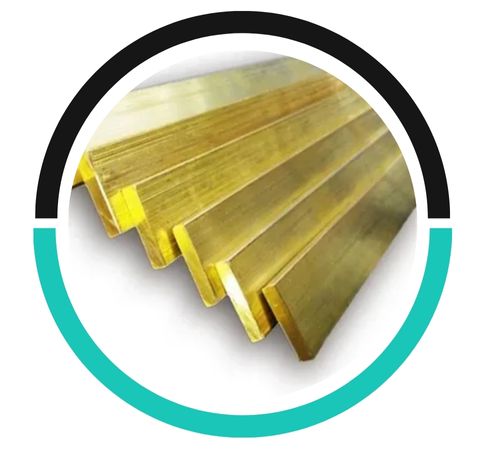

Neil Metals, based in Kolkata, India, has earned a solid reputation as a reliable manufacturer and supplier of Aluminium Bronze Bars and Rods. They provide high-performance metal solutions to a variety of industries both in India and around the world. Known for their technical know-how and unwavering commitment to quality, Neil Metals delivers Aluminium Bronze products that stand out for their remarkable strength, corrosion resistance, and durability, even in the toughest conditions. With cutting-edge facilities and rigorous quality control measures, the company customizes bars and rods to meet a wide range of specifications. They cater to industries like marine, aerospace, and heavy engineering, ensuring that their products are dependable and come with timely delivery and outstanding customer service.

Aluminium Bronze Bars and Rods are mainly made up of copper (80–90%) and aluminum (5–11%), with small amounts of iron, nickel, and manganese added to boost strength and corrosion resistance. These alloys boast impressive mechanical properties, featuring a tensile strength of 500–800 MPa along with good elongation and wear resistance. Their exceptional resistance to seawater corrosion and oxidation makes them perfect for extreme environments. Additionally, Aluminium Bronze provides good thermal conductivity, fatigue strength, and dimensional stability, making it an excellent choice for precision-machined and heavy-duty industrial components.

| Standards | ASTM B150, ASME SB150, BS, IS, JIS,DIN, UNI, AMS 4640, UNS C63000/C63200/C95800/C95510, UZ19AL6, AMS 4880 |

| Standard | ASTM, ASME, AMS, GB/T, JIS |

| Length | 100 mm To 3000 mm Long & Above, Random, Fix & Cut Length or as per clients’ requirement |

| Size | 5 mm To 500 mm |

| Diameter | 0.1-600mm |

| Finish | Bright, Polish |

| Type | Hot-Rolled (HR) / Cold-Rolled (CR) Sheet |

| Chemical Composition Limits | ||||||||

| Weight % | Cu | Al | Fe | Mn | Ni | Si | Sn | Zn |

| AMS 4640 | Bal | 9.0-11.0 | 2.0-4.0 | 1.5 | 4.0-5.5 | 0.25 | 0.20 | 0.30 |

| Material | Diameter |

Tensile Strength ksi |

Yield Strength ksi | Elongation 4D % | Hardness HB |

| AMS 4640 Annealed Bar | <1.0″ | 110 | 68 | 10 | 201-248 |

| AMS 4640 Annealed Bar | 1.0″ – 2.0″ | 110 | 60 | 10 | 201-248 |

| AMS 4640 Annealed Bar | 2.0″ – 3.0″ | 105 | 55 | 10 | 187-241 |

| AMS 4640 Annealed Bar | 3.0″ – 5.0″ | 100 | 50 | 10 | 187-241 |

To select the right aluminum bronze bar, consider factors like strength, corrosion resistance, wear resistance, temperature conditions, and alloy composition. Ensure compatibility with your specific application environment and mechanical requirements.

Aluminium bronze rods are available in various sizes, typically ranging from 1/8" to 6" in diameter. Finishes include as-forged, rough-turned, polished, and anodized for enhanced corrosion resistance.

Yes, aluminum bronze bars can be welded, typically using TIG or MIG welding methods. Preheating may be required to prevent cracking, and post-weld heat treatment helps ensure strength and integrity.

These Aluminium Bronze Bars and Rods find extensive use in industries that require top-notch corrosion resistance, mechanical strength, and durability. In the marine industry, they are perfect for applications like ship propellers, pump shafts, and seawater piping due to their ability to withstand saltwater corrosion. The aerospace and defense sectors rely on them for high-load components, landing gear parts, and bushings. They are also essential in heavy engineering, chemical processing, and oil and gas applications. Their non-sparking properties make them safe for use in explosive environments. Overall, Aluminium Bronze Bars and Rods deliver long-lasting performance in harsh, corrosive, and high-stress conditions.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved