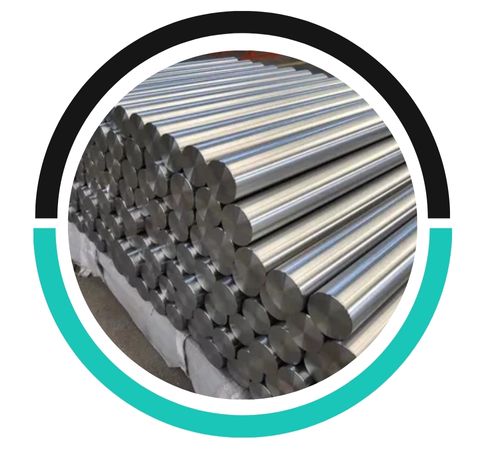

Neil Metals, located in Kolkata, India, stands out as a top manufacturer and supplier of Aluminium 7050 bars and rods, renowned for their high-strength, aerospace-grade aluminium products. Thanks to their cutting-edge manufacturing techniques and rigorous quality control, Neil Metals guarantees that their Aluminium 7050 bars and rods meet international performance and reliability standards. Catering to the aerospace, defense, automotive, and structural sectors, they offer tailored solutions that boast exceptional mechanical properties, impressive corrosion resistance, and long-lasting durability. Their dedication to precision and on-time delivery has made them a reliable partner for high-performance aluminium products in both domestic and global markets.

Aluminium 7050 bars and rods are primarily made up of aluminium (around 87%), with notable amounts of zinc (6.2%), magnesium (2.3%), and copper (2.3%), along with trace elements like chromium. This heat-treatable alloy showcases remarkable mechanical properties, featuring a tensile strength of 510–570 MPa, yield strength of 450–490 MPa, and elongation ranging from 8–12%. It also demonstrates excellent resistance to stress corrosion cracking and fatigue, along with good machinability and high toughness, making it perfect for demanding structural applications.

| Aluminium Alloy | ASTM B211, B211, B565, B316 5082, AMS 4121 |

| Standard | ASTM, ASME, AMS, GB/T, JIS |

| Aluminium Round Bar Temper | O, H12, H14, H16, H18, H22, H24, H26, H32, H112 |

| Aluminium Bar Form | Aluminium Round, Hex, Flat, Half Round, Oval, Rectangular in Black & Bright Finish |

| Aluminium Round Bar Diameter | 0.1-600mm,etc |

| Aluminium Hexagonal Bar | 0.1-600mm,etc |

| Aluminium Angle Bar Size | 0.5mm*40mm*40mm-20mm*400mm*400mm |

| Aluminium Flat Bar Thickness | 0.1-600mm,etc |

| Aluminium Flat Bar Size | 1-2500mm, etc |

| Aluminium Round Bar Length | 1-12m, Random, Fix & Cut Length or as per clients’ requirement |

| Aluminium Bar | Bright, Polish & Black |

| Weight % | Zn | Cu | Mg | Zr | Fe | Si | Mn | Ti | Cr | Others (total) |

| Minimum | 5.7 | 2.0 | 1.9 | 0.08 | – | – | – | – | – | – |

| Maximum | 6.7 | 2.6 | 2.6 | 0.15 | 0.15 | 0.12 | 0.10 | 0.06 | 0.04 | 0.15 |

| Properties | Metric | Imperial |

|---|---|---|

| Tensile strength | 515 MPa | 74695 psi |

| Yield strength | 455 MPa | 65992 psi |

| Fatigue strength | 240 MPa | 34809 psi |

| Elastic modulus | 70-80 GPa | 10153-11603 ksi |

| Poisson’s ratio | 0.33 | 0.33 |

| Elongation | 11% | 11% |

| UNS | EN | DIN,WNr | ISO |

| A97050 | EN3982 | 3.4144 | AlZn6CuMgZr |

| Size in mm | Average Weight | |

| KG/MTR | KG/FT | |

| 10 | 0.62 | 0.18 |

| 12 | 0.90 | 0.30 |

| 14 | 1.20 | 0.40 |

| 16 | 1.60 | 0.50 |

| 18 | 2.00 | 0.60 |

| 20 | 2.50 | 0.80 |

| 22 | 3.00 | 0.90 |

| 24 | 3.56 | 1.08 |

| 25 | 3.90 | 1.20 |

| 28 | 4.80 | 1.50 |

| 30 | 5.55 | 1.69 |

| 32 | 6.30 | 1.90 |

| 34 | 7.14 | 2.18 |

| 36 | 8.00 | 2.44 |

| 40 | 9.90 | 3.00 |

| 45 | 12.49 | 3.81 |

| 50 | 15.40 | 4.70 |

| 56 | 19.34 | 5.89 |

| 60 | 22.20 | 6.80 |

| 63 | 24.47 | 7.46 |

| 63.5 | 24.86 | 7.58 |

| 65 | 26.05 | 7.94 |

| 70 | 30.20 | 9.20 |

| 73 | 32.86 | 10.00 |

| 75 | 34.72 | 10.58 |

| 78 | 37.51 | 11.43 |

| 80 | 39.50 | 12.00 |

| 83 | 42.47 | 12.95 |

| 85 | 44.55 | 13.58 |

| 90 | 50.00 | 15.20 |

| 92 | 52.19 | 15.91 |

| 93 | 53.39 | 16.27 |

| 95 | 55.65 | 16.95 |

| 100 | 61.66 | 18.79 |

| 105 | 67.98 | 20.72 |

| 110 | 74.60 | 22.74 |

| 115 | 81.64 | 24.88 |

| 125 | 96.34 | 29.36 |

Yes, Aluminium 7050 bars are ideal for structural applications, particularly in aerospace and military sectors, offering high strength, corrosion resistance, and fatigue resistance, making them suitable for demanding environments and designs.

To maintain Aluminium 7050 bars, regularly clean them with mild soap and water to remove dirt and debris. Avoid harsh chemicals, inspect for corrosion, and store in a dry, cool environment.

Yes, Aluminium 7050 rods are highly recyclable. Aluminium, including alloy 7050, can be recycled multiple times without losing its properties, making it an environmentally friendly choice for sustainable manufacturing and use.

Industries that require a high strength-to-weight ratio and outstanding corrosion resistance widely use Aluminium 7050 bars and rods. In the aerospace sector, they are essential for aircraft structural components, fuselage frames, and wing skins. In defense, they find applications in military vehicles and missile parts due to their durability and resistance to fatigue. The automotive industry utilizes Aluminium 7050 for high-performance components, while the marine sector relies on it for corrosion-resistant structural parts. Additionally, it is well-suited for high-stress engineering applications where strength, toughness, and resistance to environmental factors are crucial.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved