Neil Metals stands out as a top-notch manufacturer and supplier of high-quality Alloy Steel F91 Bars and Rods, proudly based in Kolkata, India. Known for its commitment to precision engineering and strict adherence to international standards, Neil Metals provides durable and high-performance alloy steel products that cater to the needs of demanding industries. The company specializes in crafting F91 grade bars and rods, which are celebrated for their remarkable strength, high-temperature resistance, and corrosion-resistant features. With a team of skilled professionals and state-of-the-art manufacturing facilities, Neil Metals guarantees consistent quality and timely delivery to clients both in India and around the globe.

Alloy Steel F91 Bars and Rods are primarily made up of chromium (8–9.5%) and molybdenum (0.85–1.05%), along with trace amounts of vanadium, carbon, manganese, phosphorus, sulfur, and silicon. These elements work together to boost the alloy’s hardness, strength, and resistance to heat and corrosion. On the mechanical side, F91 boasts impressive tensile strength (minimum 585 MPa), yield strength (minimum 415 MPa), and good elongation (minimum 20%), making it perfect for high-stress environments. The blend of these mechanical and chemical properties ensures that it performs reliably in demanding applications.

|

type |

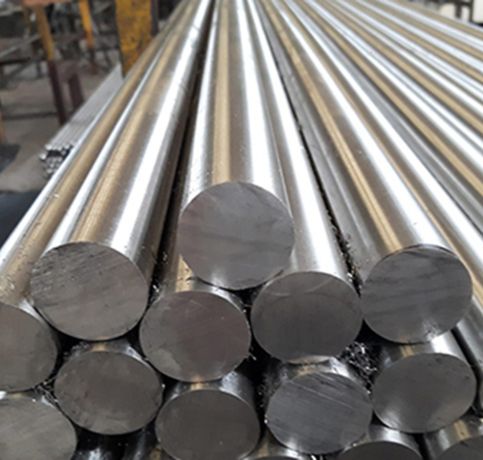

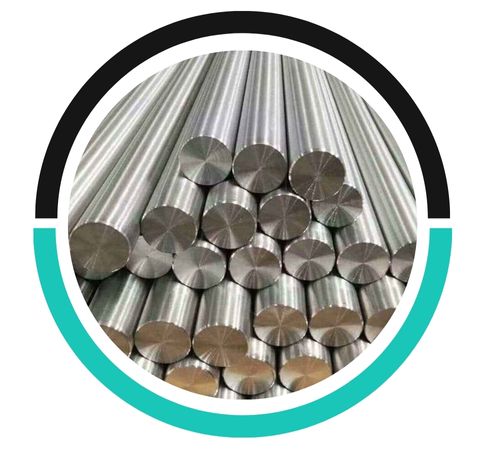

Alloy Steel ASTM A182 F91 Round Bars |

|

|

Type |

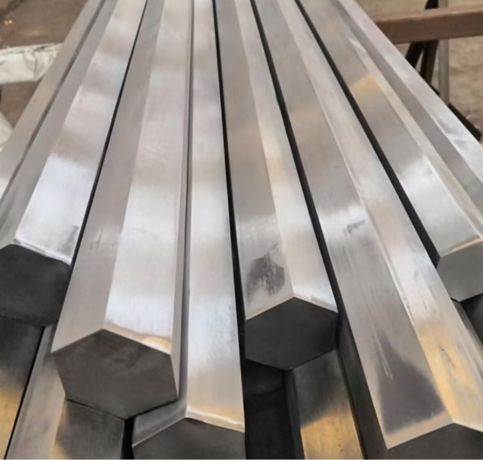

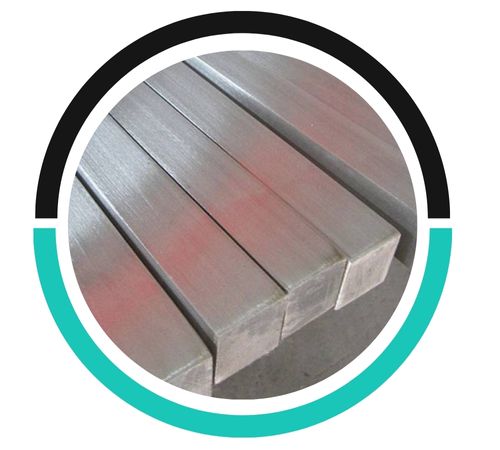

rod, square bar, Round bar, hexagon bar, flat bar, channel bar, angle bar, threaded bar |

|

|

Standards |

Alloy Steel ASTM A182 F91 , A479, A314, GB4226-84, GB/T1220-2007, JISG4311-91, JIS G4318-98, EN 10095-99, GB4226-84, EN10088-3-2005, JIS G3033-2005, etc |

|

|

Surface |

bright round bar, pickled round bar, black round bar |

|

|

Package Details |

Standard seaworthy package(wooden boxes package,pvc package, or other package) |

|

|

Technique |

Forged/Hot Rolled/Cold Drawn/Peeled |

|

|

Range |

Range – 3.17mm to 350mm dia |

|

|

Diameter |

|

|

|

Length |

1m-9m or according to the customer’s requirement |

| Grade | C | Mn | Si | Mo | P | Cr |

| ASTM A182 F91 | 0.08 – 0.15 | 0.30 – 0.60 | 0.20 – 0.50 | 0.85 – 1.05 | 0.020 | 8.0 – 9.5 |

| Tensile Strength (ksi) min | Elongation (% in 50mm) min | Yield Strength 0.2% Proof (ksi) min |

| 570 | 23 | 295 |

| STANDARD | WERKSTOFF NR. | UNS |

| ASTM A182 F91 | 1.4903 | – |

|

SHAPE |

POUNDS PER FOOT |

|---|---|

|

Round |

D2 x 2.67 |

|

Hexagon |

D2 x 2.945 |

|

Square |

D2 x 3.4 |

|

Flat |

Thickness (in.) x Width (in.) x 3.4 |

Alloy Steel F91 Bars and Rods are primarily used in high-temperature and high-pressure applications such as power plants, pressure vessels, and heat exchangers due to their strength and resistance to oxidation.

Alloy Steel F91 offers excellent tensile strength, high-temperature resistance, and good oxidation and corrosion resistance, making it ideal for demanding industrial applications.

Alloy Steel F91 performs exceptionally well in extreme environments, maintaining strength and integrity under high-temperature and high-pressure conditions, making it ideal for critical components.

You’ll find Alloy Steel F91 Bars and Rods widely used in sectors like power generation, petrochemicals, refineries, and heat exchangers, thanks to their outstanding performance under high pressure and temperature conditions. These rods are particularly well-suited for boiler components, pressure vessels, and piping systems in both thermal and nuclear power plants. Their excellent creep resistance and structural stability at elevated temperatures make them a dependable choice for critical applications. Plus, F91 bars are also used in the fabrication of valves, flanges, and fittings, ensuring safety and efficiency in complex industrial operations.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved