Neil Metals, located in Kolkata, India, has built a solid reputation as a manufacturer and supplier of top-notch Alloy Steel F2 Bars and Rods. With a strong foothold in both domestic and international markets, the company is celebrated for its precision-engineered products that adhere to global standards. Thanks to state-of-the-art manufacturing facilities and rigorous quality control processes, Neil Metals consistently delivers high-performance F2 alloy bars tailored to meet a variety of industrial needs. Their dedication to excellence, prompt delivery, and customer satisfaction has made them a go-to partner in the alloy steel industry.

Alloy Steel F2 Bars and Rods are primarily made up of carbon, manganese, silicon, and chromium, with small amounts of molybdenum that boost their strength and durability. These bars are known for their excellent machinability, moderate tensile strength, and outstanding hardening capabilities. In terms of mechanical properties, they boast a tensile strength of around 600 MPa, a yield strength of about 300 MPa, and impressive impact resistance, making them perfect for heat-treated components. The steel retains its dimensional stability and hardness even after machining, ensuring reliability for precision applications.

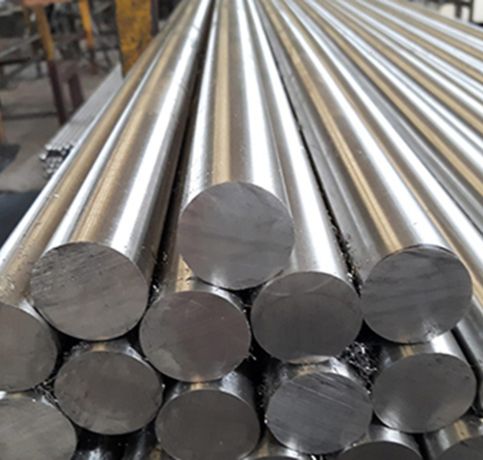

Alloy Steel Round Bar Specification : ASTM A182, ASME SA182

Dimension Standard : EN, DIN, JIS, ASTM, BS, ASME, AISI

Size : 14mm-300mm

Thickness : 50 mm to 6000 mm Long

Length : 1 To 6 Meters, Custom Cut Length

Form : Round, Square, Hex(A/F), Rectangle, Billet, Ingot, Forging Etc.

| Grade | C | Mn | P | S | Si | Ni | Ch | Mo | Cb |

|---|---|---|---|---|---|---|---|---|---|

| F1 | 0.28 | 0.60 – 0.90 | 0.045 | 0.045 | 0.15 – 0.30 | – | – | 0.44-0.65 | – |

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

|---|---|---|---|---|---|

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| F1 | 485 | 275 | 20 | – | 143-192 |

| STANDARD | UNS | WERKSTOFF NR. |

|---|---|---|

| Alloy Steel F1 | K12822 | 1.5415 |

They are used in high-temperature applications like pressure vessels, heat exchangers, and boilers, primarily in power generation and aerospace industries.

The combination of Chromium, Molybdenum, and Carbon enhances its resistance to oxidation and high-temperature degradation.

They offer a tensile strength of 600-850 MPa and a yield strength of 450 MPa, ensuring durability and performance in demanding conditions.

Due to their machinability and strength, Alloy Steel F2 Bars and Rods are widely utilized across various industries. They are perfect for crafting tools, jigs, fixtures, shafts, and machine components that demand dimensional accuracy and wear resistance. Their ability to endure heat treatment makes them ideal for automotive parts, heavy engineering, and general mechanical applications. In the aerospace and defense sectors, these rods are employed in components that require high stability under mechanical stress. Additionally, they are used in die-making and industrial equipment where dependable performance and durability are crucial.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved