Neil Metals, located in Kolkata, India, has built a solid reputation as a reliable manufacturer and supplier of high-quality Alloy Steel AISI 4130 Bars and Rods. They cater to industries that prioritize strength, toughness, and weldability. Renowned for their precision-engineered alloy steel products, Neil Metals guarantees that each bar and rod adheres to international quality and performance standards. With cutting-edge manufacturing capabilities and a strong focus on customer satisfaction, the company serves various sectors, including aerospace, oil & gas, automotive, and structural engineering. Neil Metals is well-regarded for its dedication to timely deliveries, technical know-how, and tailored alloy steel solutions for critical, high-performance applications.

Alloy Steel AISI 4130 Bars and Rods consist of about 0.28–0.33% carbon, 0.40–0.60% manganese, 0.80–1.10% chromium, 0.15–0.25% molybdenum, along with trace elements of silicon, phosphorus, and sulfur, with the rest being iron. These bars boast an impressive strength-to-weight ratio, good hardenability, and excellent impact resistance. Their mechanical properties include a tensile strength ranging from 560 to 670 MPa and a yield strength of approximately 460 MPa. The alloy is highly weldable and can undergo heat treatment processes like quenching and tempering, making it perfect for high-stress structural and mechanical applications.

| Dimensions | : | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Size | : | 5 mm To 500 mm |

| Diameter | : | 0.1 mm to 100 mm |

| Length | : | 100 mm To 3000 mm Long & Above |

| Finish | : | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

| Tolerance | : | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

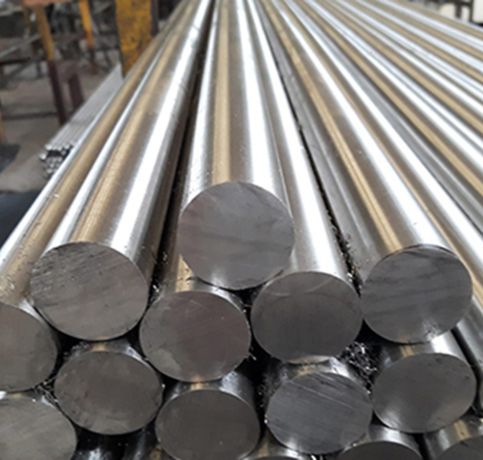

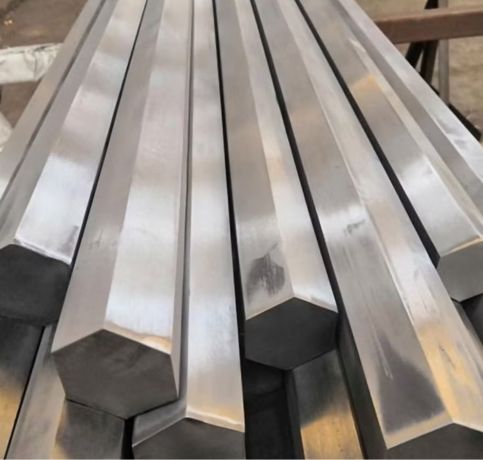

| Form | : | Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc. |

| Grade | C | Mn | Si | P | S | Fe | Mo | Ni | Cr |

| AISI 4130 | 0.28-0.33 | 0.40-0.60 | 0.15-0.35 | 0.035 max | 0.025 MAX | 97.3-98.22 | 0.15-0.25 | 0.50 max | 0.80-1.10 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.85 g/cm3 | 1432 ℃ | 560 | 460 | 21.50% |

Alloy Steel AISI 4130 Bars and Rods offer exceptional strength, toughness, and resistance to wear due to their chromium and molybdenum content. These properties make them ideal for high-stress and high-temperature environments across industries like aerospace, automotive, and oil and gas.

Yes, our AISI 4130 Bars and Rods can undergo heat treatments such as quenching and tempering to enhance their mechanical properties, including increased hardness, strength, and toughness, for specialized applications.

Our AISI 4130 Bars and Rods are widely used in aerospace for structural components, in automotive for gears and shafts, and in oil and gas for pipelines and drilling equipment, thanks to their durability and adaptability.

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | EN |

| AISI 4130 | 1.7218 | G41300 | JIS G4105 | BS 970 | 25CrMo4 |

Alloy Steel AISI 4130 Bars and Rods find extensive use in scenarios where a blend of strength, ductility, and weldability is essential. In the aerospace industry, they are utilized for structural components, landing gear parts, and airframe tubing. The oil & gas sector relies on them for drill collars, mud motor shafts, and pipeline fittings, thanks to their toughness and fatigue resistance. In automotive and motorsports, AISI 4130 is favored for roll cages, suspension parts, and steering components. Additionally, it plays a crucial role in industrial machinery, power plants, and the fabrication of pressure vessels, owing to its outstanding mechanical performance under dynamic loads.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved